Embedded inductor structure and manufacturing method thereof

A manufacturing method and embedded technology, applied in the field of inductance, can solve the problems of low space utilization rate of vertical inductance, low utilization rate of metal wires, and difficult control of inductance value, so as to achieve performance optimization, reduce area, and ensure verticality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

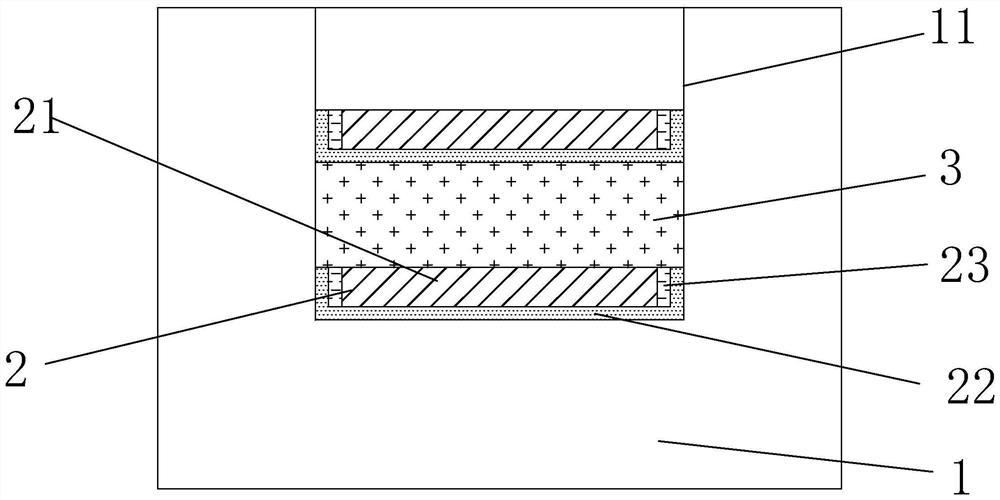

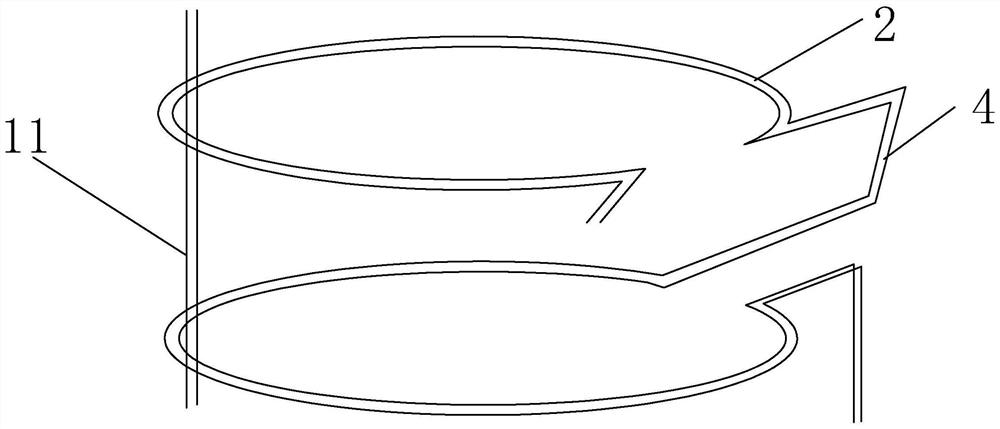

[0034] refer to figure 1 , the embedded inductor structure proposed by the embodiment of the present application includes a substrate 1 , a coil structure 2 and a second dielectric layer 3 . There is a trench 11 with a certain depth on the substrate 1, and a plurality of coil structures 2 and the second dielectric layer are stacked in the trench 11 to form an embedded inductor. Wherein, the thickness of the substrate 1 is 625-665 μm, and the material of the substrate 1 includes Si or GaAs. The depth of the trench 11 is 10 μm˜100 μm, and the sidewall of the trench 11 has a certain verticality in the substrate 1 . Specifically, the included angle between the sidewall of the ditch 11 and the bottom of the ditch 11 is 88°-92°. The coil structure 2 is arranged at intervals from the bottom of the trench 11 along the depth direction of the trench 11 to form a multi-layer coil, and a second dielectric layer 3 is arranged between two adjacent coil structures 2, and the second dielect...

Embodiment 2

[0047] refer to figure 1 , another embedded inductance structure, the difference from the first embodiment is that the adhesion layer is Si, and the metal layer is fabricated by using a self-aligned silicide (Salicide) process in step 4. Thus in case the adhesion layer is Si, the metal layer is deposited on the surface of the Si layer, and the metal layer is in contact with the surface of the Si layer. Then heat treatment is performed to form a silicide metal layer on the surface of the contact metal layer and the silicon layer. In step 5, the first dielectric layer and the Si layer on the sidewall of the trench above the silicide metal layer are removed, wherein the metal layer can be selected.

Embodiment 3

[0049] refer to Figure 4 , another embedded inductance structure, the difference from Embodiment 1 is that there is an air cavity 5 between two adjacent coil structures. Specifically, in step 6, a sacrificial material is filled between two adjacent coil structures, and the second dielectric layer is set as a sacrificial layer. In the manufacturing method, step 8 further includes: forming an air cavity 5 between adjacent upper and lower coils by opening holes and removing the sacrificial layer after the upper coil is manufactured. Sacrificial material can choose SOG.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com