LCD backlight module convenient to demount

A backlight module, a technology for easy disassembly, applied in optics, nonlinear optics, instruments, etc., can solve the problems of inconvenient disassembly, lower economic efficiency, and affect the efficiency of replacement and disassembly, so as to facilitate disassembly, improve work efficiency, and work efficiency Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

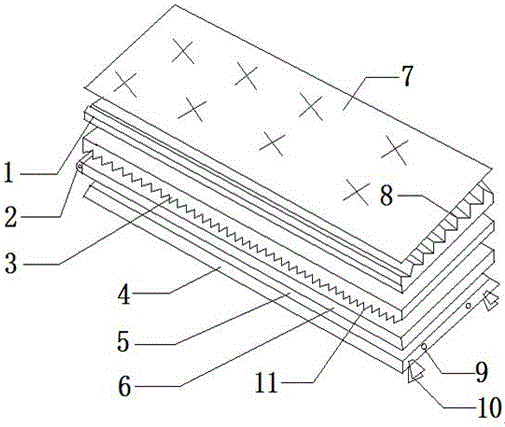

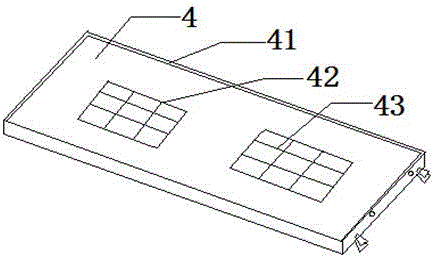

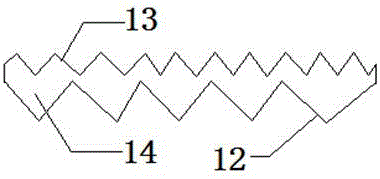

[0019] This example provides Figure 1-3 The LCD backlight module shown as a convenient disassembly includes a fixed base 4 and a reflective sheet 5, a light guide plate 6 is arranged above the reflective sheet 5, and a light emitting module 2 is installed on the left side of the light guide plate 6. The top of the light guide plate 6 is provided with a reverse-edge light-condensing sheet 3, and the bottom of the reverse-edge light-condensing sheet 3 is provided with a reverse-prism surface 11. A prism surface 8 is laid on the upper surface of the prismatic light concentrating sheet 1, an upper diffusion sheet 7 is arranged above the positive prismatic light concentrating sheet 1, and a through hole 9 is opened on the right side edge of the fixed base 4, and the left side of the through hole 9 A fixing clip 10 is provided, the fixing base 4 includes a heat dissipation window 42 , a protective pad 41 is arranged inside the fixing base 4 , and the heat dissipation window 42 is c...

Embodiment 2

[0022] This example provides Figure 1-3 The LCD backlight module shown as a convenient disassembly includes a fixed base 4 and a reflective sheet 5, a light guide plate 6 is arranged above the reflective sheet 5, and a light emitting module 2 is installed on the left side of the light guide plate 6. The top of the light guide plate 6 is provided with a reverse-edge light-condensing sheet 3, and the bottom of the reverse-edge light-condensing sheet 3 is provided with a reverse-prism surface 11. A prism surface 8 is laid on the upper surface of the prismatic light concentrating sheet 1, an upper diffusion sheet 7 is arranged above the positive prismatic light concentrating sheet 1, and a through hole 9 is opened on the right side edge of the fixed base 4, and the left side of the through hole 9 A fixing clip 10 is provided, the fixing base 4 includes a heat dissipation window 42 , a protective pad 41 is arranged inside the fixing base 4 , and the heat dissipation window 42 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com