Method for manufacturing drilling display panel and silk screen board

A technology of screen printing screen and display panel, applied in nonlinear optics, instruments, optics, etc., can solve the problem of easy leakage of liquid crystal, rupture and separation of array substrate and color filter substrate, and inability to completely and reliably seal the sealant in the drilling area, etc. problems, to achieve complete and reliable sealing, improve product quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

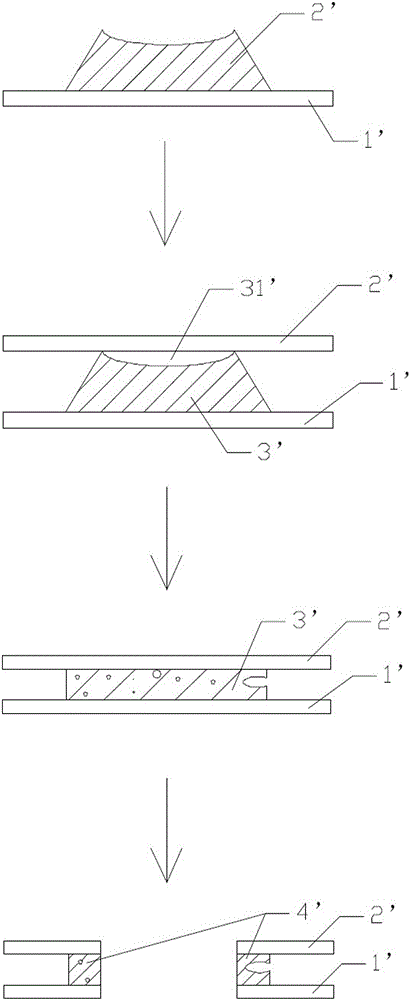

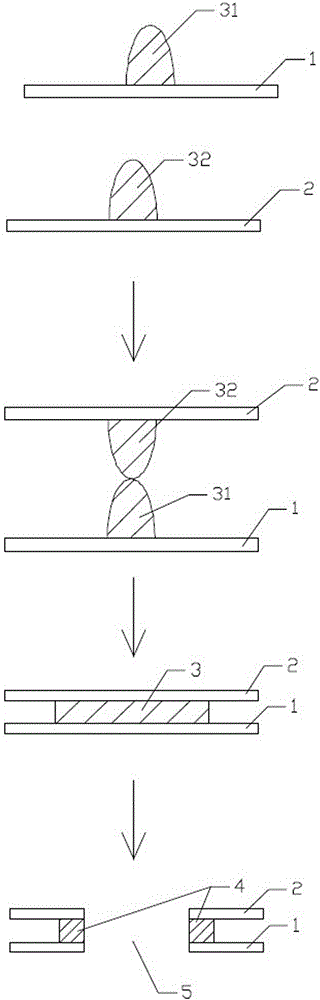

Method used

Image

Examples

Embodiment 1

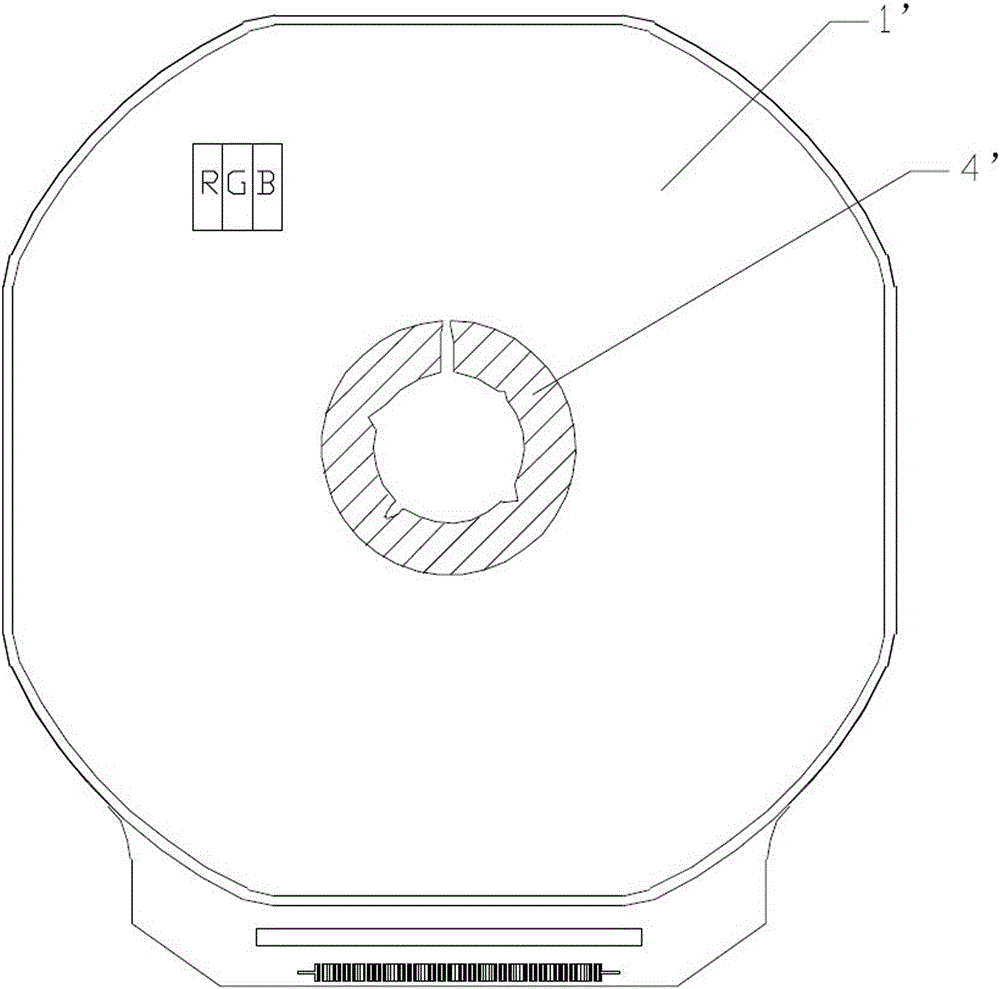

[0040] A method for manufacturing a drilled display panel, selecting the drilled hole diameter d of the drilled display panel 2 About 2.0mm, sealing ring width d 3 About 0.6mm, then the curing diameter d 1 About 3.5mm, the volume of sealant in the drilling area (that is, the amount of sealant required in the drilling area) V 1 About π(3.5 / 2) 2 *h 1 ; the method includes the following steps:

[0041] An array substrate and a color filter substrate are provided; the array substrate has a drilling area, a display area, and a frame area, and the display area is between the drilling area and the frame area; the color filter substrate is connected to the array substrate Correspondingly, there is a drilling area, a display area and a frame area on it, and the display area is between the drilling area and the frame area;

[0042] Provide the first screen printing screen and the second screen printing screen; the first screen printing screen adopts 305M mesh, the thickness of the ...

Embodiment 2

[0048] A method for manufacturing a drilled display panel, selecting the drilled hole diameter d of the drilled display panel 2 About 2.0mm, sealing ring width d 3 About 0.6mm, then the curing diameter d 1 About 3.5mm, the volume of sealant in the drilling area (that is, the amount of sealant required in the drilling area) V 1 About π(3.5 / 2) 2 *h 1 ; the method includes the following steps:

[0049] An array substrate and a color filter substrate are provided; the array substrate has a drilling area, a display area, and a frame area, and the display area is between the drilling area and the frame area; the color filter substrate is connected to the array substrate Correspondingly, there is a drilling area, a display area and a frame area on it, and the display area is between the drilling area and the frame area;

[0050] Provide the first screen printing screen and the second screen printing screen; the first screen printing screen adopts 305M mesh, the thickness of the ...

Embodiment 3

[0056] A method for manufacturing a drilled display panel, selecting the drilled hole diameter d of the drilled display panel 2 About 2.0mm, sealing ring width d 3 About 0.6mm, then the curing diameter d 1 About 3.5mm, the volume of sealant in the drilling area (that is, the amount of sealant required in the drilling area) V 1 About π(3.5 / 2) 2 *h 1 ; the method includes the following steps:

[0057] An array substrate and a color filter substrate are provided; the array substrate has a drilling area, a display area, and a frame area, and the display area is between the drilling area and the frame area; the color filter substrate is connected to the array substrate Correspondingly, there is a drilling area, a display area and a frame area on it, and the display area is between the drilling area and the frame area;

[0058] Provide the first screen printing screen and the second screen printing screen; the first screen printing screen adopts 305M mesh, the thickness of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com