BP neural network-based anti-dazzle glass chemical erosion technological parameter optimization method

A BP neural network and process parameter optimization technology, applied in neural learning methods, biological neural network models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

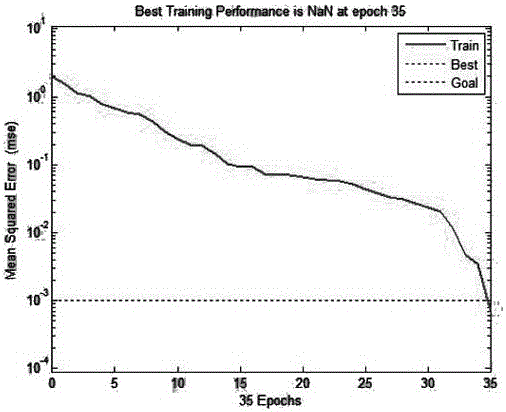

[0027] The anti-glare glass chemical erosion process parameter optimization method based on BP neural network comprises the following steps:

[0028] S1: Data processing, establishing the anti-glare glass chemical erosion process data set, which includes the erosion temperature, erosion time data and glass transmittance data corresponding to the erosion temperature and erosion time during the anti-glare glass chemical erosion process, and Normalize the glass transmittance in the dataset:

[0029] ;

[0030] Among them, μ is the mean of all sample data, σ is the standard deviation of all sample data, For the normalized glass transmittance data, is the glass transmittance data before normalization;

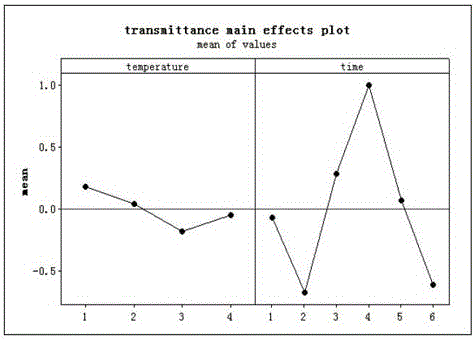

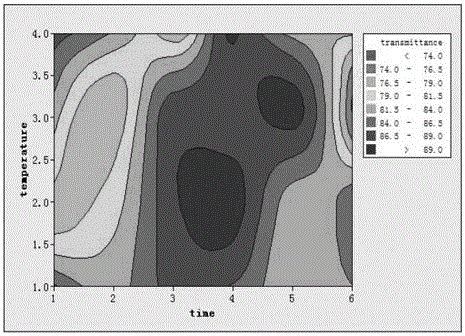

[0031] In the experimental data of chemical etching process research on anti-glare glass, tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com