Battery heating method and heating system and battery

A battery and heating sheet technology, applied in the battery field, can solve the problems of lithium-ion battery discharge capacity decay greatly, migration rate slow down, and affect the use of mobile terminals by users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Certain terms are used throughout the description and claims to refer to particular components. It should be understood by those skilled in the art that manufacturers may use different terms to refer to the same component. The specification and claims do not use the difference in name as a way to distinguish components, but use the difference in function of components as a basis for distinction. The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

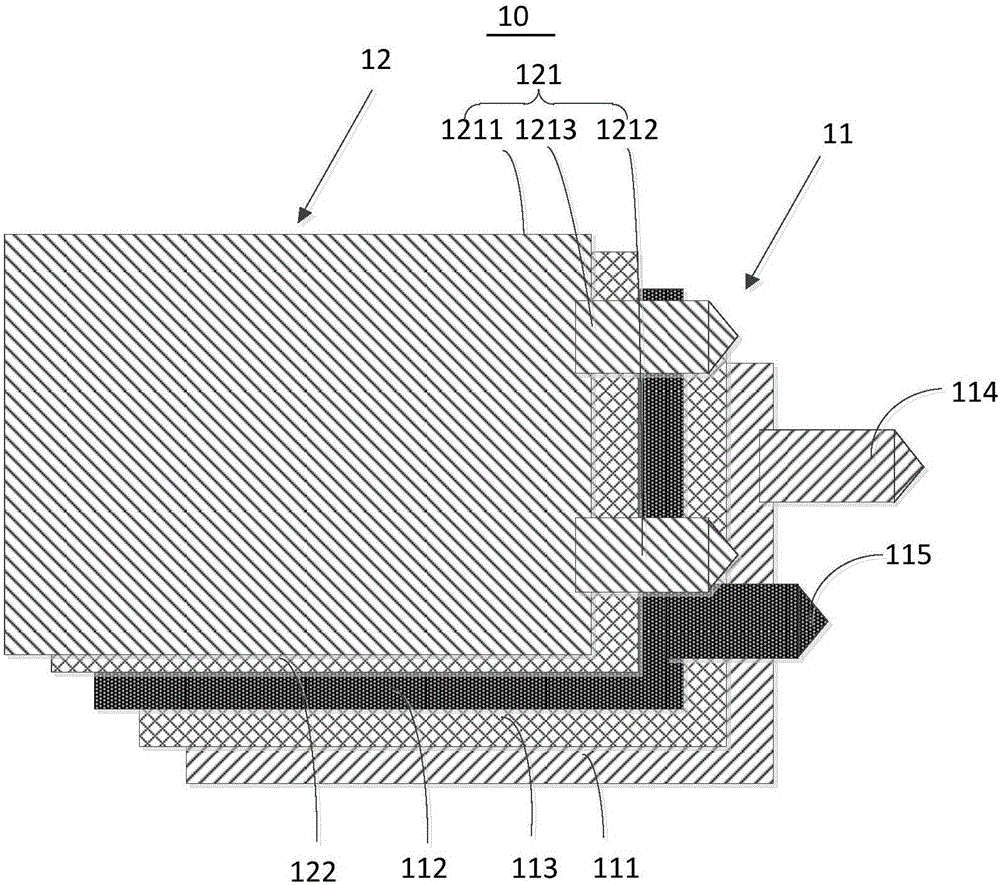

[0020] figure 1 It is a structural schematic diagram of the battery of the embodiment of the present invention. Such as figure 1 As shown, the battery 10 includes a battery core 11 , a switch circuit (not shown) and a heating device 12 disposed on the outer surface of the battery core 11 .

[0021] The battery core 11 includes a positive electrode sheet 111 wound with each other, a negative electrode sheet 112, a first separator 113 spaced between the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com