Cable stripping device

A technology for cables and pipes, applied in the field of cable stripping devices, can solve the problems of inability to adjust and inconvenient use, and achieve the effects of easy processing, simple design structure and stable cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing and specific implementation example:

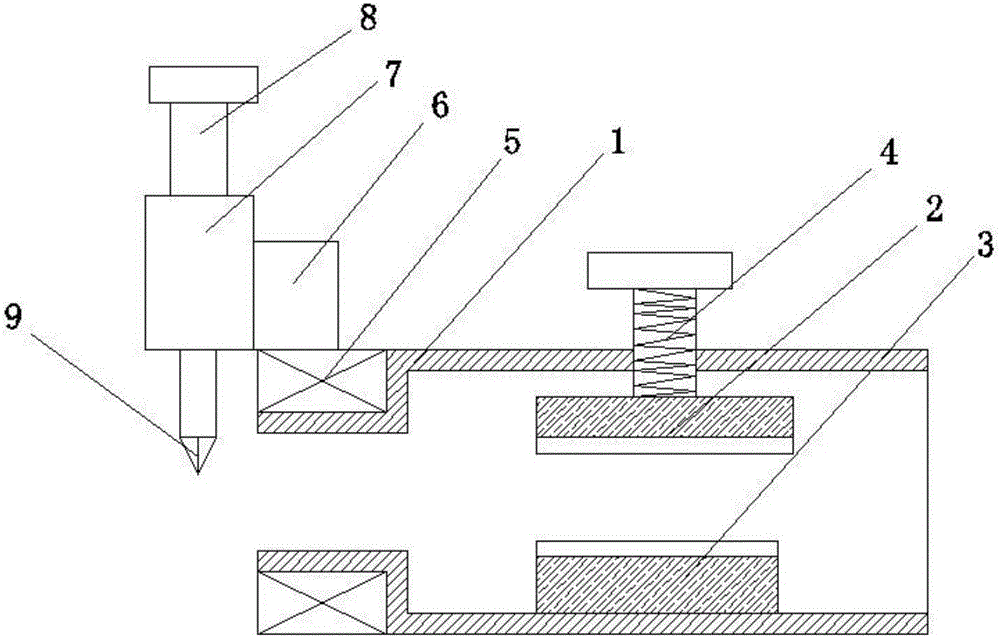

[0015] Such as figure 1 As shown, a cable stripping device includes a pipe 1, a clamping block 2, a fixing block 3, a thumb screw 4, a bearing 5, a connecting block 6, a hydraulic rod 7, a hydraulic rod adjustment part 8 and a blade 9, the described The inside of the pipe 1 is provided with a fixed block 3, and the clamping block 2 is set on the pipe 1 and above the fixed block 3 through the thumb screw 4, and the clamping block 2 can move up and down under the action of the thumb screw 4 , the cable is fixed by the clamping block 2 and the fixing block 3 to facilitate the subsequent peeling work; the front end of the pipe 1 is provided with a bearing 5, and the bearing 5 is directly welded together with the hydraulic rod 7 through the connecting block 6; the described One end of the hydraulic rod 7 is provided with a hydraulic rod adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com