A Distributed Fault Detection and Isolation Method with Adaptive Characteristics

A distributed and fault-based technology, applied in the field of feeder automation, can solve problems such as error-prone, cumbersome and abnormal on-site maintenance, and achieve the effect of simple on-site implementation and operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

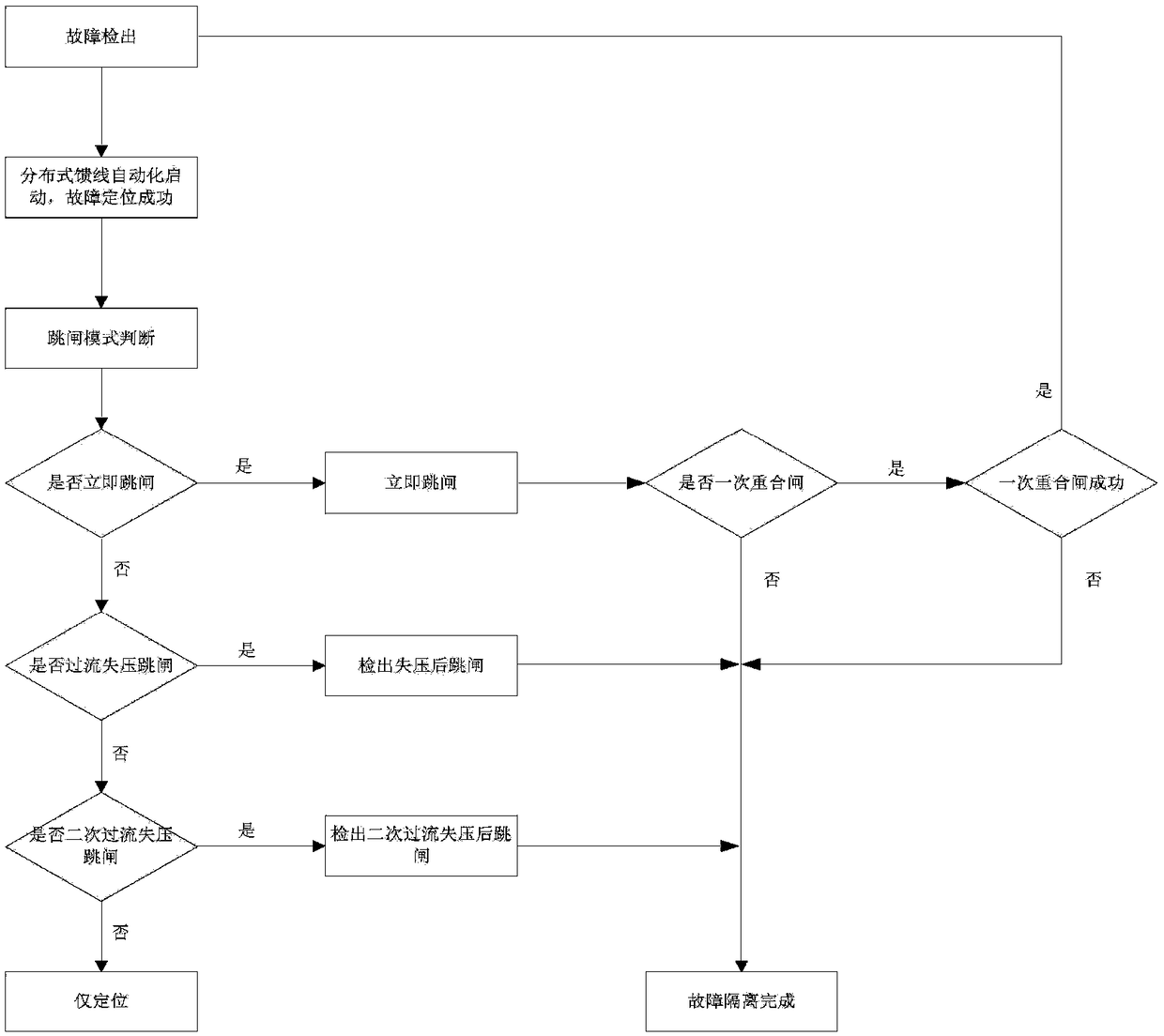

[0024] Such as Figure 1~2 As shown, a distributed fault detection and isolation method with adaptive characteristics is characterized in that: when the transmission line detects a line fault for the first time, the distributed feeder automation starts immediately, and through the information exchange of adjacent switchgear, First complete the fault location, and immediately trip the faulty equipment that has been located according to the trip mode and complete the fault isolation.

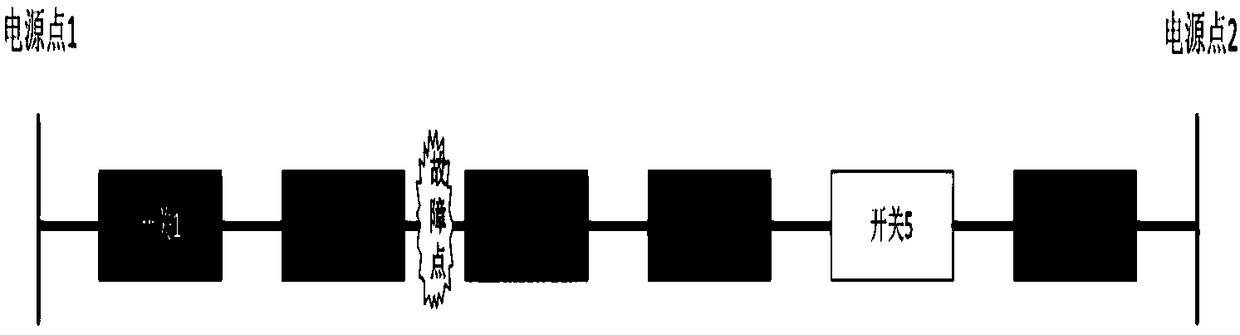

[0025] During the test as figure 2 As shown, according to the technical scheme of the present invention, each switch and terminal equipment are formed into a hand-in-hand line, wherein switch 1 and switch 6 are substation outlet circuit breakers, switch 2-switch 5 are line switches, and the line fault occurs in switch 2 and switch Between 3, each switch and each circuit breaker a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com