Gap correction mechanism and half nut fastening device of injection molding machine having same

A technology of injection molding machine and correction mechanism, which is applied in the field of split nut fastening devices, which can solve the problems that the load cannot be applied evenly, the simultaneous tightening action of split nuts cannot be accurately performed, and cannot be completely removed, so as to improve durability and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

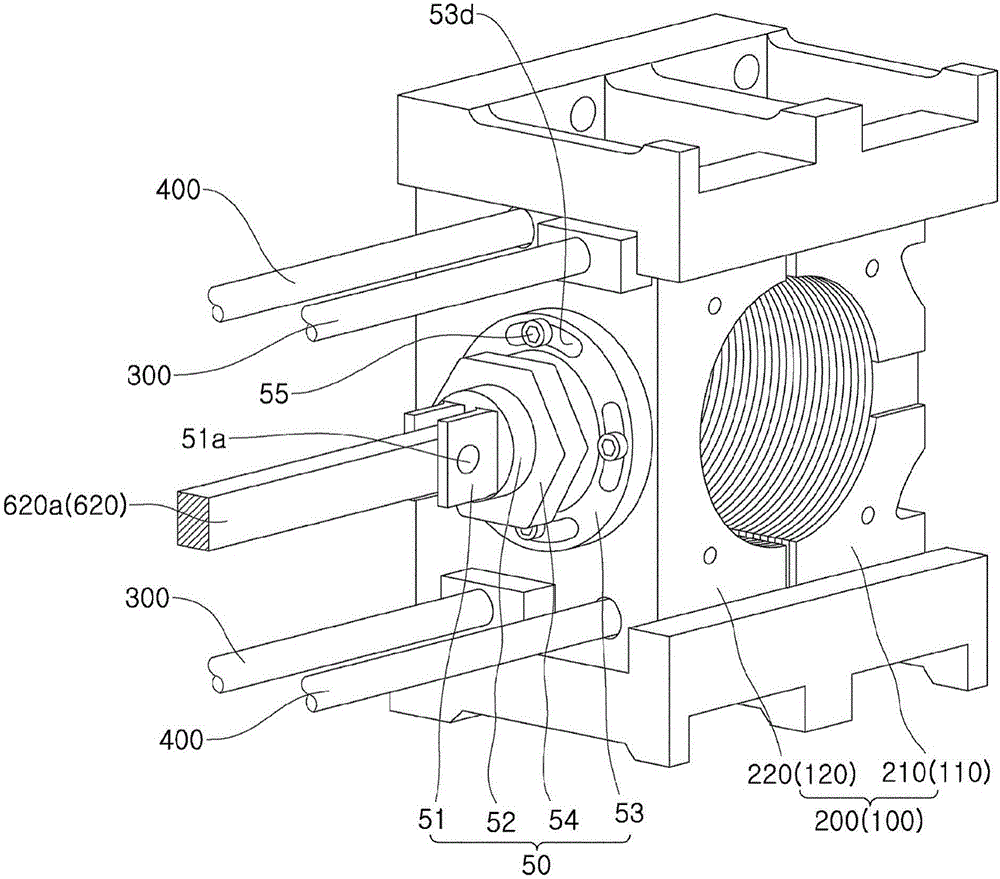

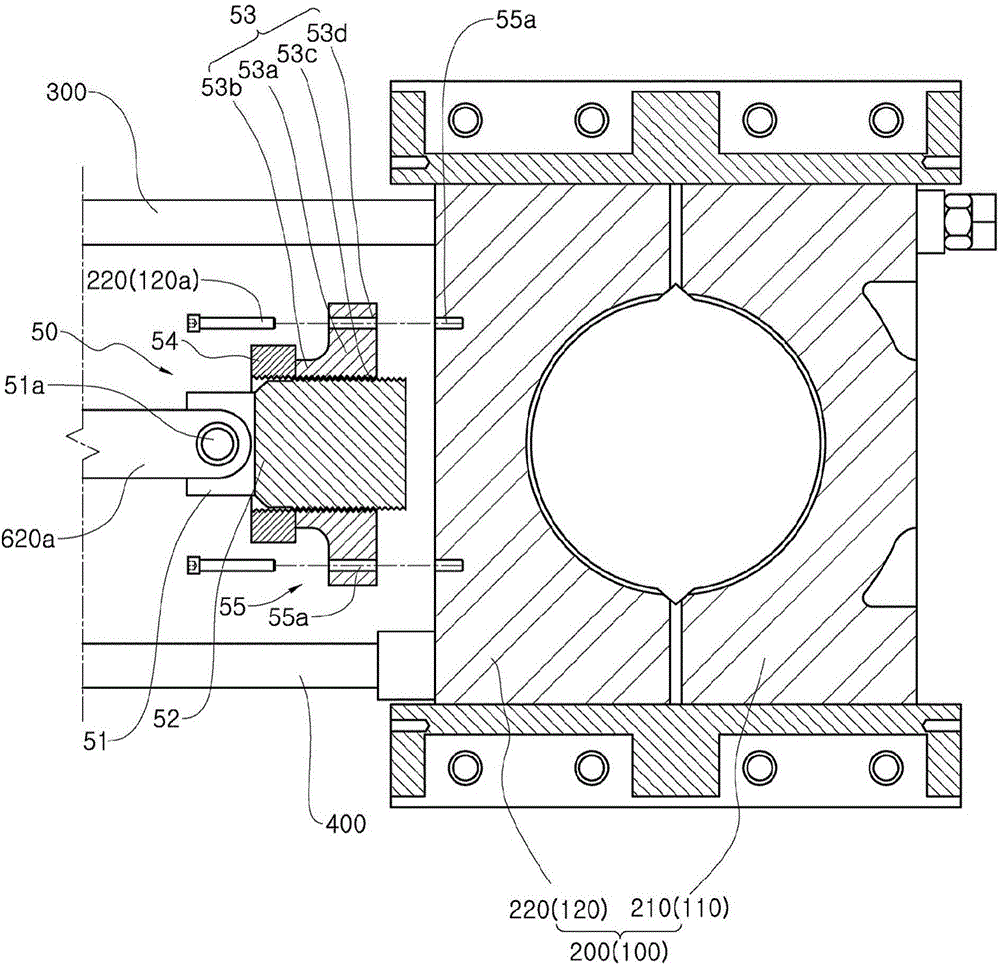

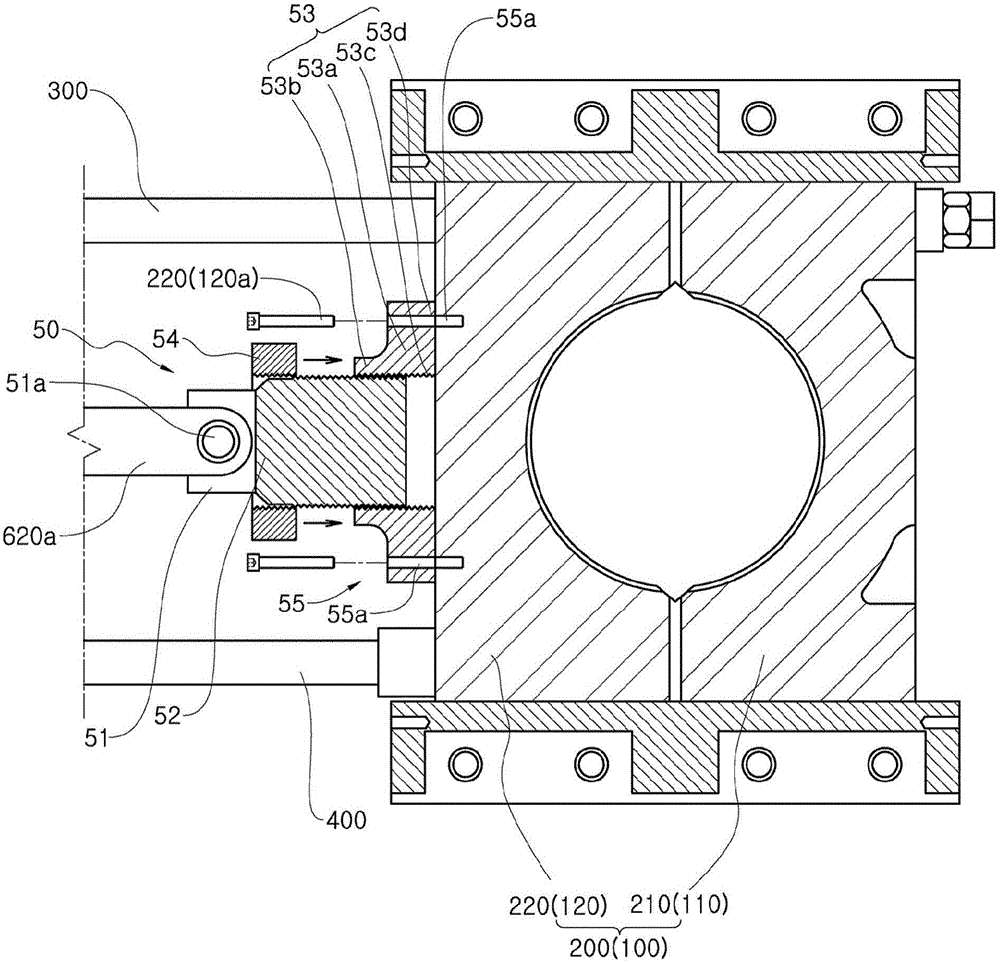

[0055] Below, the specific content of implementing the present invention will be described in detail according to the attached example diagrams.

[0056] figure 1 It is a perspective view showing a one-side split nut fastening device provided with a backlash correction mechanism according to an embodiment of the present invention, figure 2 is as figure 1 Combined cross-sectional view of , a schematic diagram of the state of the fixed part of the backlash correction mechanism before contacting the side of the split nut. image 3 is a schematic diagram of the state when the above-mentioned fixing part contacts the side surface of the split nut, Figure 4 It is a schematic diagram of a state in which the fixing part is connected to the side surface of the split nut through a fixing nut and a fastening member.

[0057] First, refer to figure 1 , among the first split nuts 110, 210 and the second split nuts 120, 220 constituting the left and right split nuts 100, 200, a gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com