Preparation method and application of chip with hydrophilic-super-hydrophobic composite interface

A super-hydrophobic and interfacial technology, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve problems such as unfavorable mass production, achieve the effect of increasing stability and durability, and improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

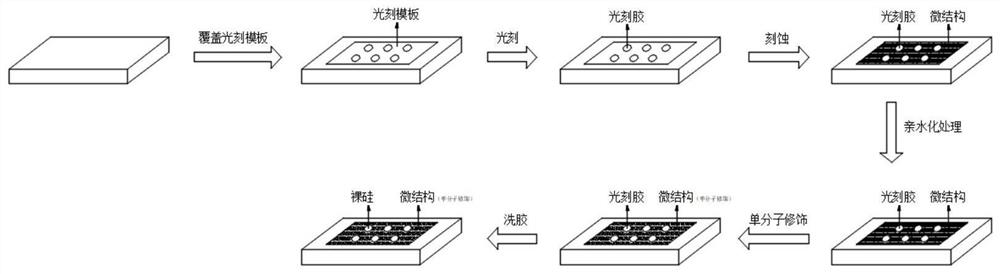

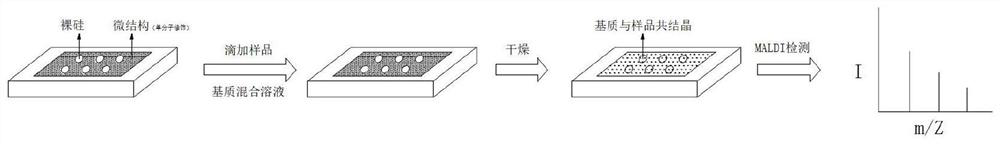

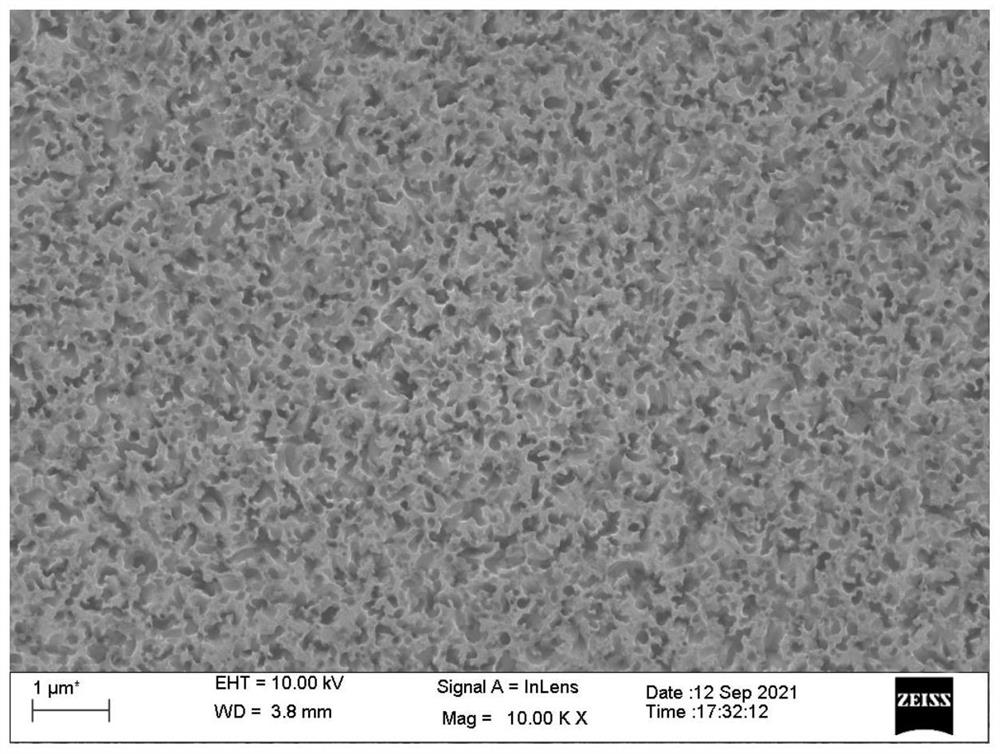

[0050] Select single-crystal silicon as the substrate, put the single-crystal silicon substrate into acetone, chloroform, ethanol, and ultrapure water successively for ultrasonic cleaning, take out the substrate to dry, and put the dried substrate into H 2 SO 4 :H 2 o 2 =In a mixed solution of 3:1, heat at 80°C for 30 minutes, rinse with water, and blow dry with nitrogen; evenly spin-coat positive-type photoresist on the substrate, the spin-coating condition is 500-5000 rpm, and the time is 5-5 50s; place the photolithography mask on the above substrate, wherein the size of the mask pattern is 100-2000μm, the pitch is 500-5000μm, and expose it under the ultraviolet lamp, the exposure time is 2-300s; the exposed substrate Put it into the developing solution for development, then take out the substrate, and dry it with nitrogen gas to obtain the photoresist dot matrix; use O to obtain the substrate 2 -Plasma was treated with a power of 200W for 10 minutes for hydrophilization...

Embodiment 2

[0052] Select a stainless steel sheet as the substrate, put the stainless steel sheet substrate into acetone, chloroform, ethanol, and ultrapure water for ultrasonic cleaning respectively, take out the substrate to dry, and put the dried substrate into H 2 SO 4 :H 2 o 2 =In a mixed solution of 3:1, heat at 100°C for 10 minutes, rinse with water, and blow dry with nitrogen; evenly spin-coat positive-type photoresist on the substrate, the spin-coating condition is 500-5000 rpm, and the time is 5-5 50s; place the photolithography mask on the above substrate, wherein the size of the mask pattern is 100-2000μm, the pitch is 500-5000μm, and expose it under the ultraviolet lamp, the exposure time is 2-300s; the exposed substrate Put it into the developing solution for development, then take out the substrate, and dry it with nitrogen gas to obtain the photoresist dot matrix; use O to obtain the substrate 2 -Plasma was treated with a power of 200W for 10 minutes for hydrophilizatio...

Embodiment 3

[0054] Select quartz as the substrate, place the quartz substrate in acetone, chloroform, ethanol, and ultrapure water for ultrasonic cleaning, take out the substrate and dry it, and use O 2 -Plasma was treated with a power of 200W for 10 minutes to perform hydrophilic treatment, rinsed with water, and dried with nitrogen; evenly spin-coated positive-type photoresist on the substrate, the spin-coating condition was 500-5000 rpm, and the time was 5 ~50s; place the photolithography mask on the above substrate, wherein the size of the mask pattern is 100-2000μm, the pitch is 500-5000μm, and expose it under the ultraviolet lamp, the exposure time is 2-300s; the exposure time is 2-300s; Put the substrate into the developing solution for development, then take out the substrate, and dry it with nitrogen gas to obtain the photoresist dot matrix; put the obtained substrate into H 2 SO 4 :H 2 o 2 = 3:1 mixed solution, heated at 80°C for 30min, rinsed with water, and blown dry with n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com