Turbomachine turbine blade comprising cooling circuit with improved homogeneity

一种涡轮机、叶片的技术,应用在移动叶片的冷却领域,能够解决冷却不均质等问题,达到提高冷却均质性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

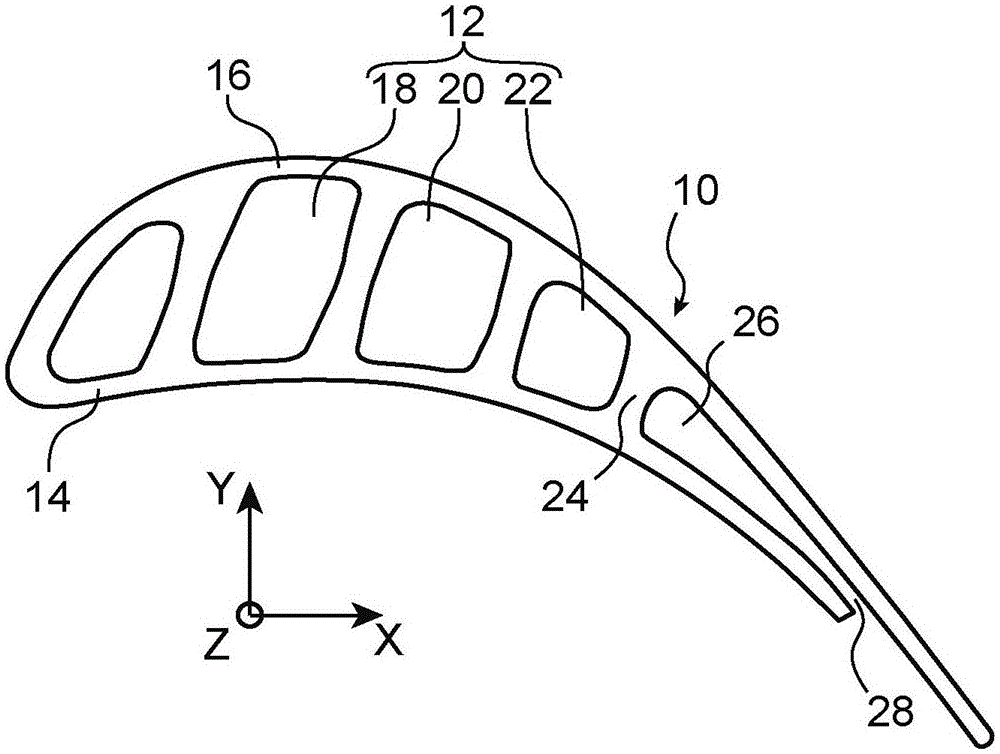

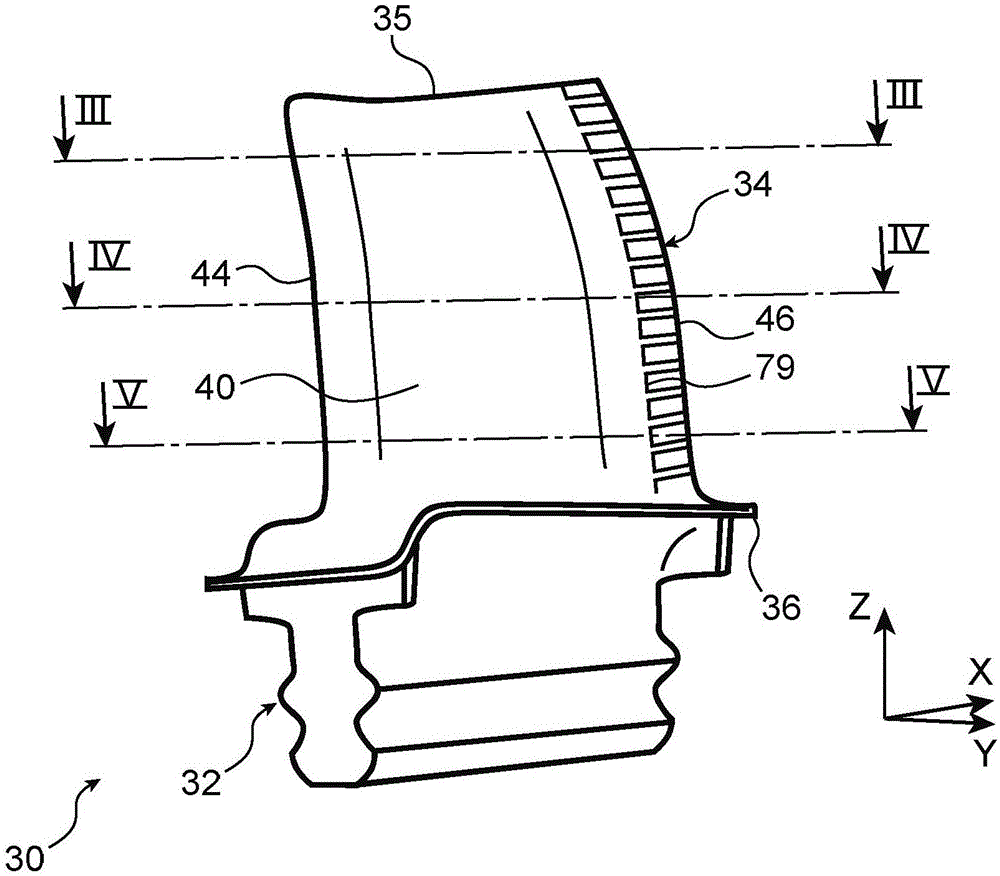

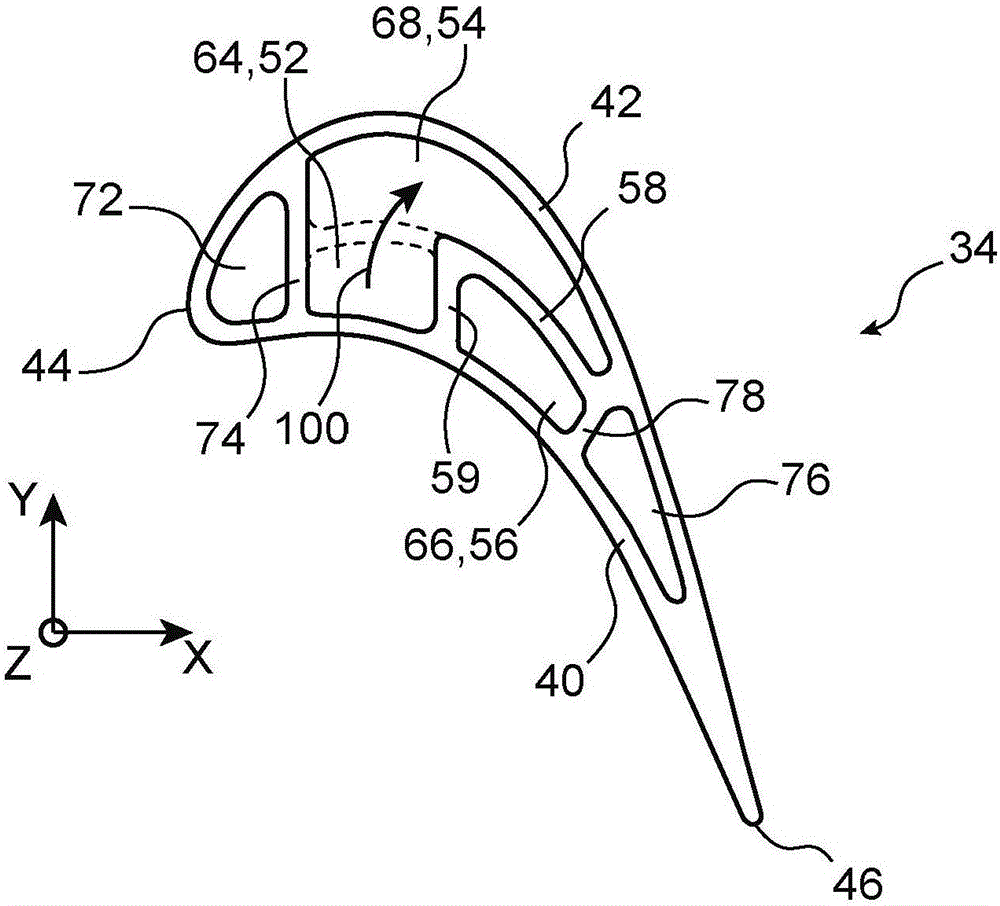

[0049] figure 2 A blade 30 for an aircraft turbine is shown according to a preferred embodiment of the present invention, generally comprising a blade root 32 to which an airfoil part 34 terminating at a tip 35 of the blade is connected on the opposite side of the blade root 32 . The blade root comprises a radially inner portion for retaining the blade in the rotor disk by a slip fit in a known manner. Furthermore, the blade root is connected to the airfoil part by an aerodynamic platform 36 which serves to internally define the main flow channel within the turbine.

[0050]In this description, the direction X is the direction corresponding to the direction of the engine axis when the blades 30 are mounted on the rotor disk inside the turbine wheel. Direction Z is a radial direction with respect to direction X, which merges with the direction of the length or span of the blade. The direction Y is such that the three directions X, Y and Z form an orthogonal reference coordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com