valve assembly

A valve assembly and component technology, applied in valve devices, safety valves, balance valves, etc., can solve the problems of large installation space, valve assembly occupation, huge construction cost, installation cost and maintenance cost, etc., to achieve short installation error chain, Space-saving, highly dynamic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

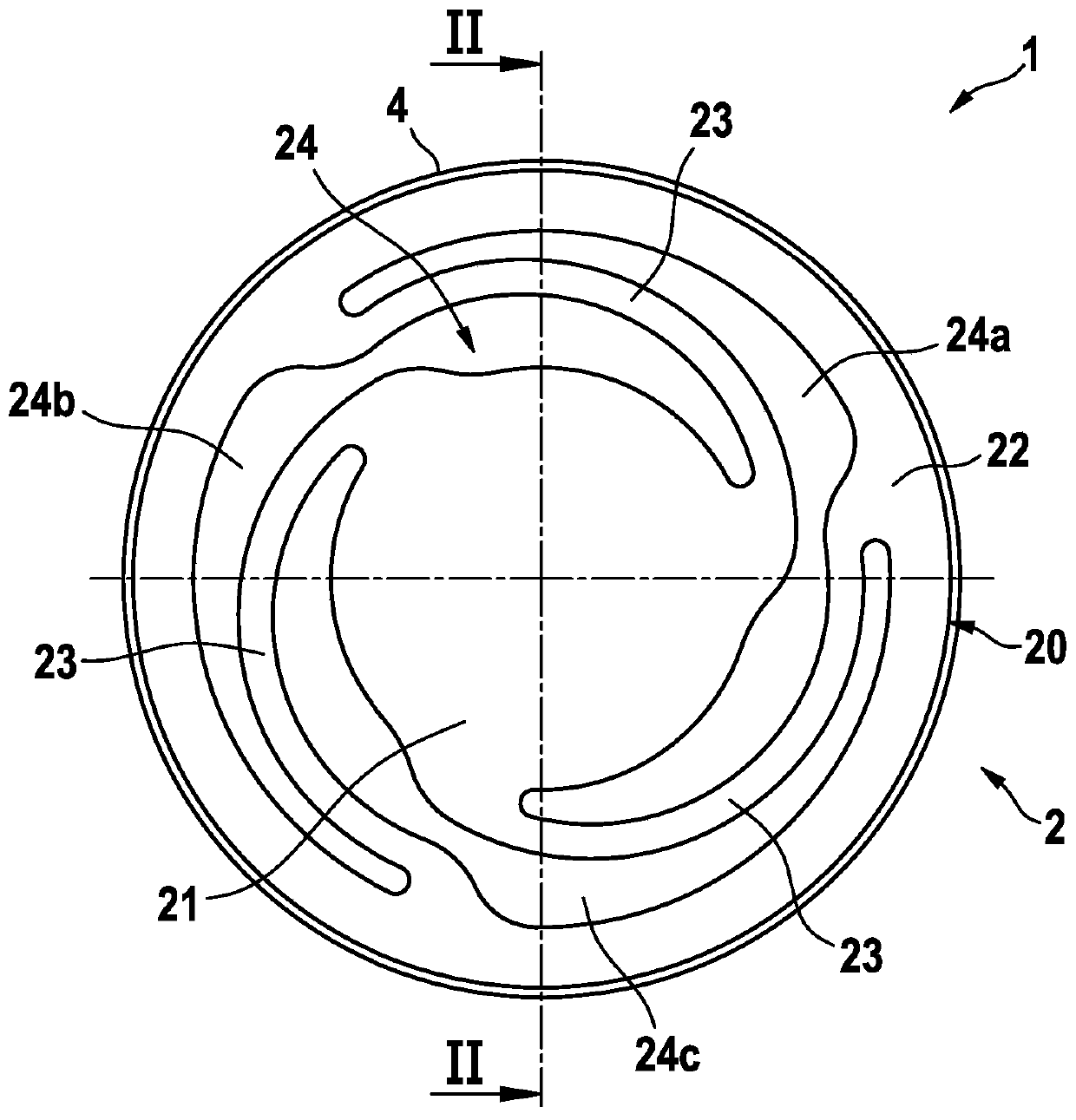

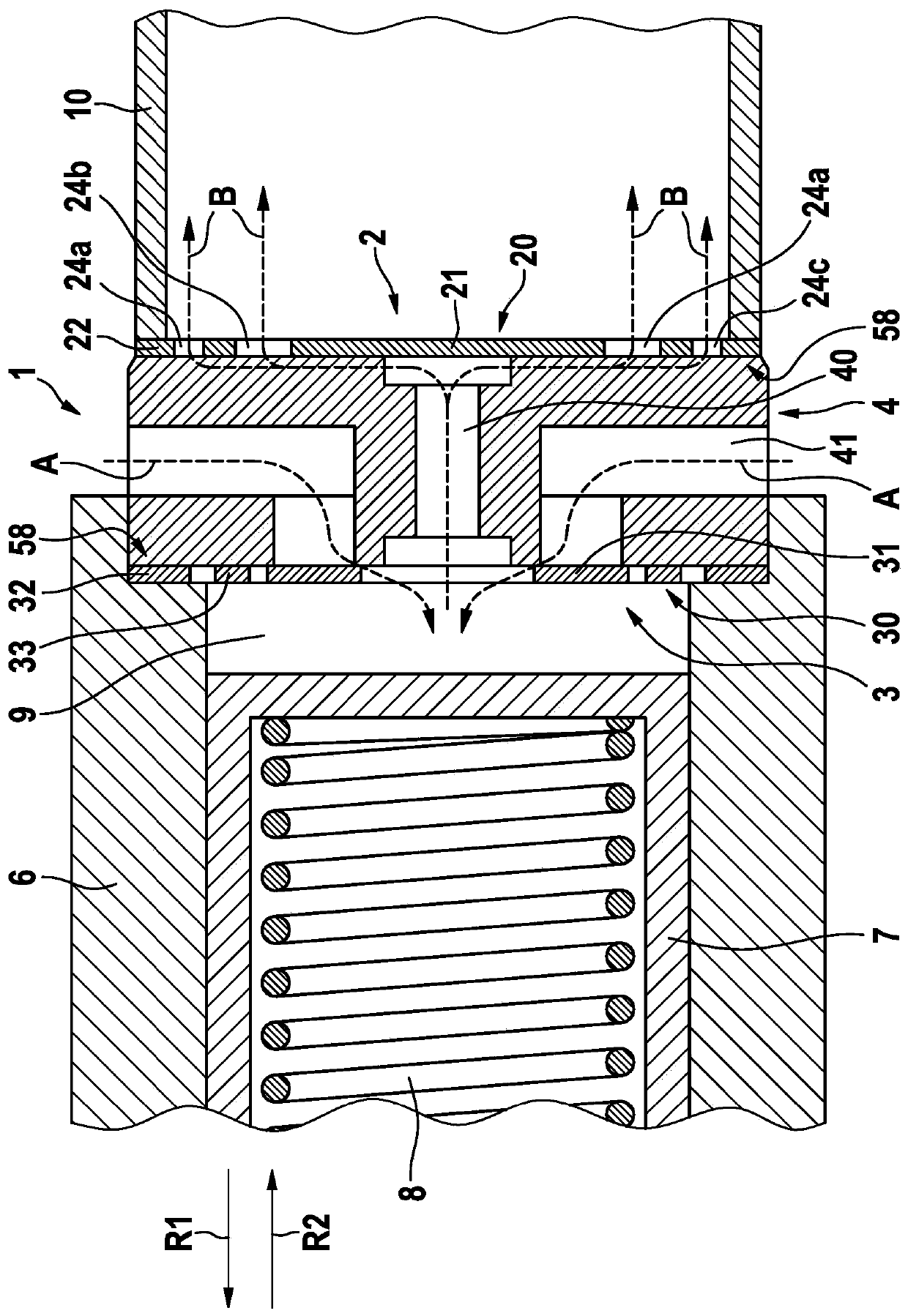

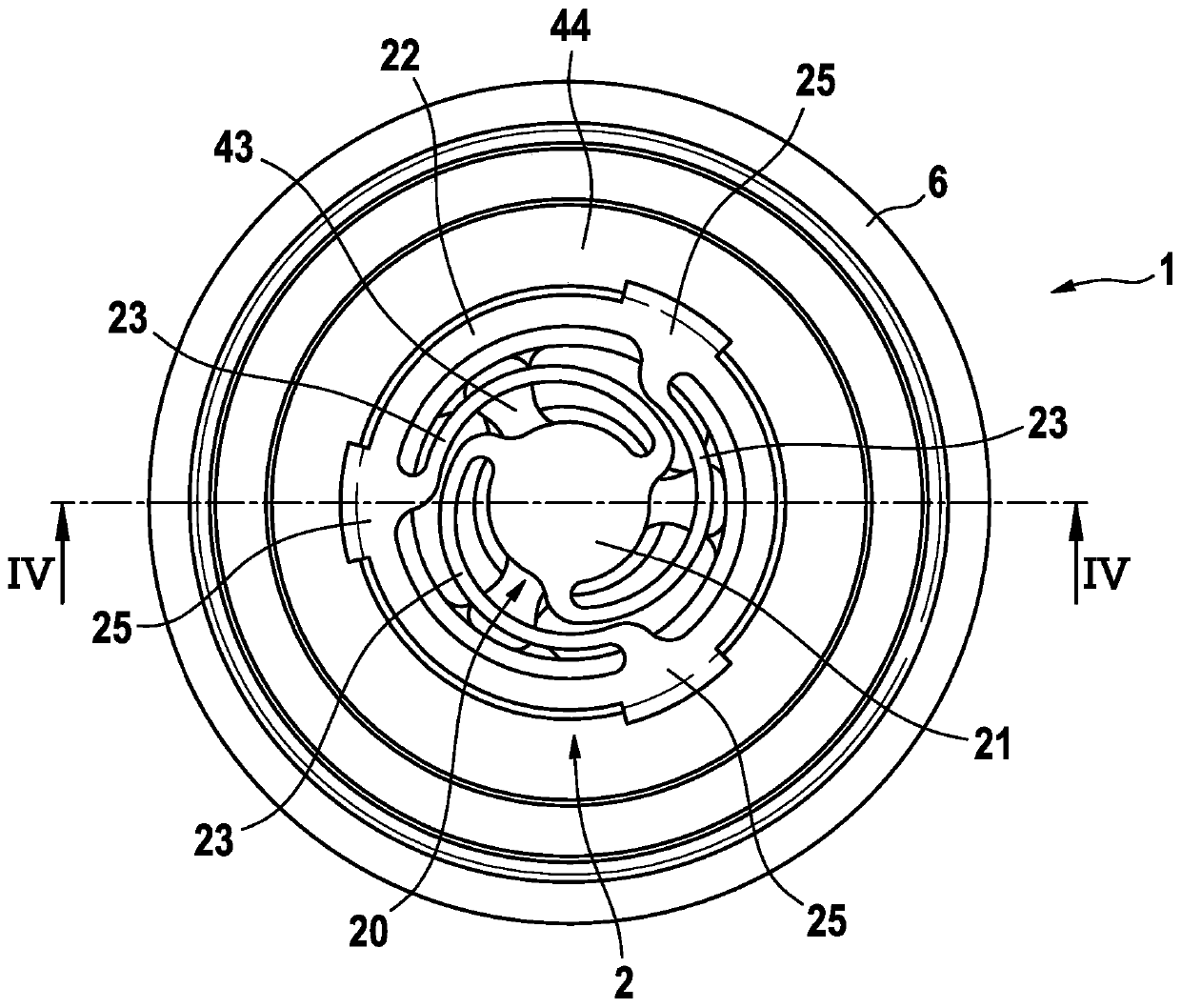

[0032] Next refer to figure 1 with 2 The valve assembly 1 according to the first preferred embodiment of the present invention is explained in detail.

[0033] figure 1 A top view of a valve assembly 1 according to the invention is shown. figure 2 shown from the left figure 1 A sectional view of the valve assembly 1 of FIG. 1 , wherein the piston 7 with the reset element 8 and the outlet opening 10 arranged in the cylinder 6 are schematically additionally shown in a section for explaining the mode of operation of the valve assembly 1 .

[0034] as from figure 2 and partly from figure 1 As can be clearly seen in FIG. 1 , the valve assembly 1 has an outlet valve 2 , an inlet valve 3 and a valve carrier 4 with a through-opening 40 . According to the invention, outlet valve 2 comprises a first diaphragm spring 20 .

[0035] exist figure 1 The first diaphragm spring 20 , better seen in , has a first inner sealing portion 21 , a first outer support portion 22 and three fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com