Heat protective shield for gas cooking appliance

A technology for cooking utensils and shielding parts is applied in the field of manufacturing gas cooking utensils, which can solve the problems of incorrect assembly of components, labor-intensive costs, complex assembly, etc., and achieve the effects of easy installation/disassembly, improved isolation performance, and reduced costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

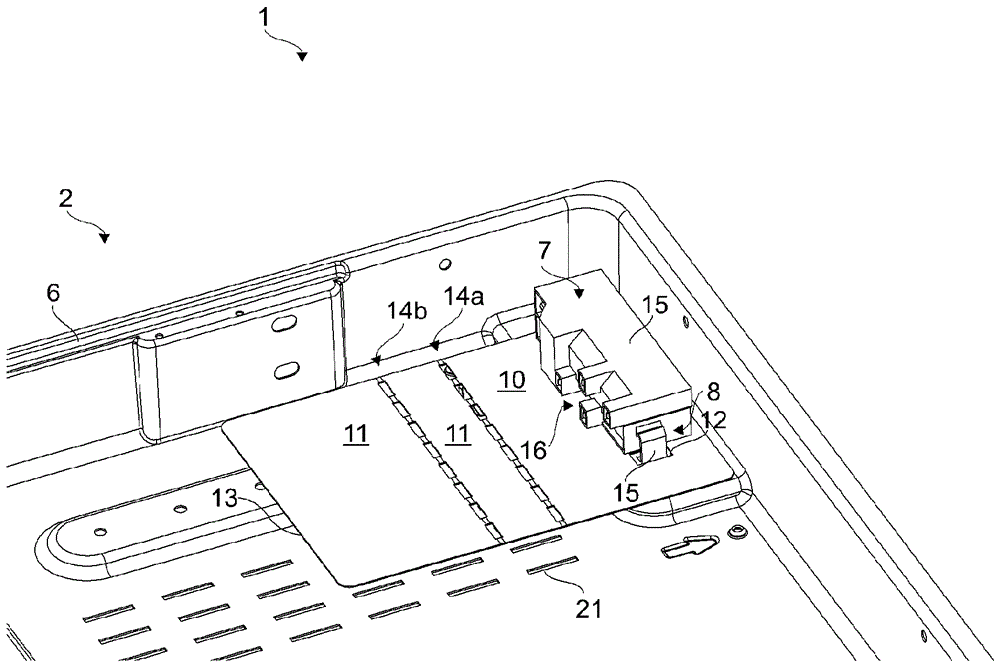

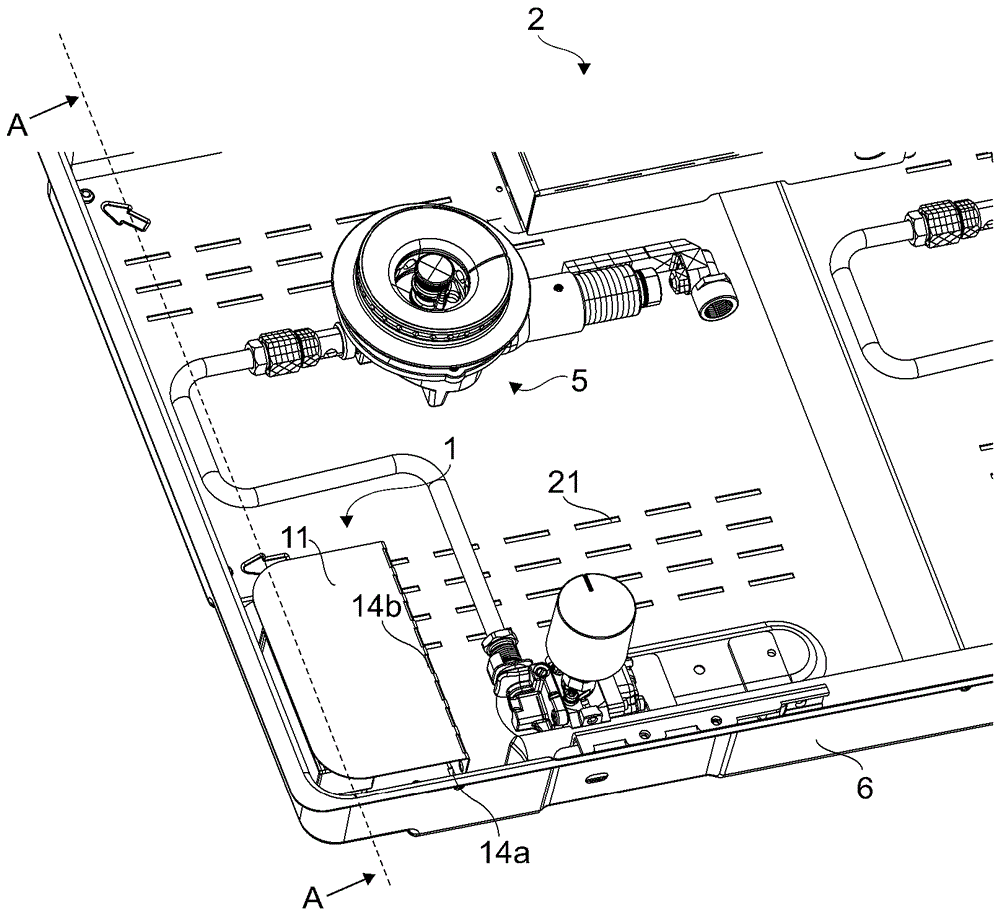

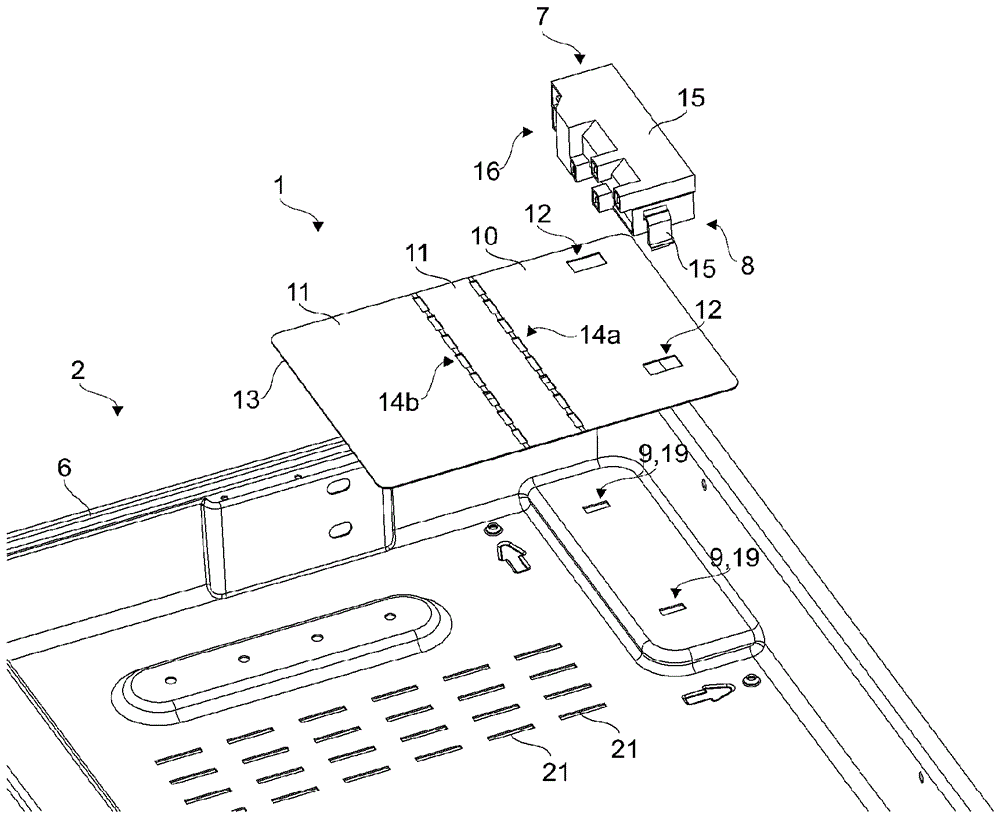

[0057] Thermally protective shield (1) suitable for use in gas cooking appliances (2) ( figure 1 to 9).

[0058] The gas cooking appliance (2) comprises a housing (3), at least one gas burner assembly (5) and at least one electrical component (7), the housing having a lower cover (6) and an upper cover (4), the at least one gas burner assembly (5) and at least one electrical component (7) A gas burner assembly (5) is mounted on the upper cover (4), and the at least one electrical component (7) is mounted on the lower cover (6) ( figure 1 to 9).

[0059]In the gas cooking appliance (2) of the present invention, the electrical component (7) has a snap-fit fastener (8) configured to mate with a pair formed on the lower cover (6) The piece (9) is releasably engaged. The gas cooking appliance (2) of the present invention further comprises a thermally protective shield (1) ( figure 1 to 9).

[0060] The thermal protective shield (1) of the present invention comprises: a base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com