Reaction kettle

A technology of reaction kettle and high pressure reaction kettle, applied in the field of reaction kettles, can solve the problems of difficulty in cleaning the reaction kettle, influence on product production, unstable quality of finished products, etc., and achieve the effects of simple structure, easy observation and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

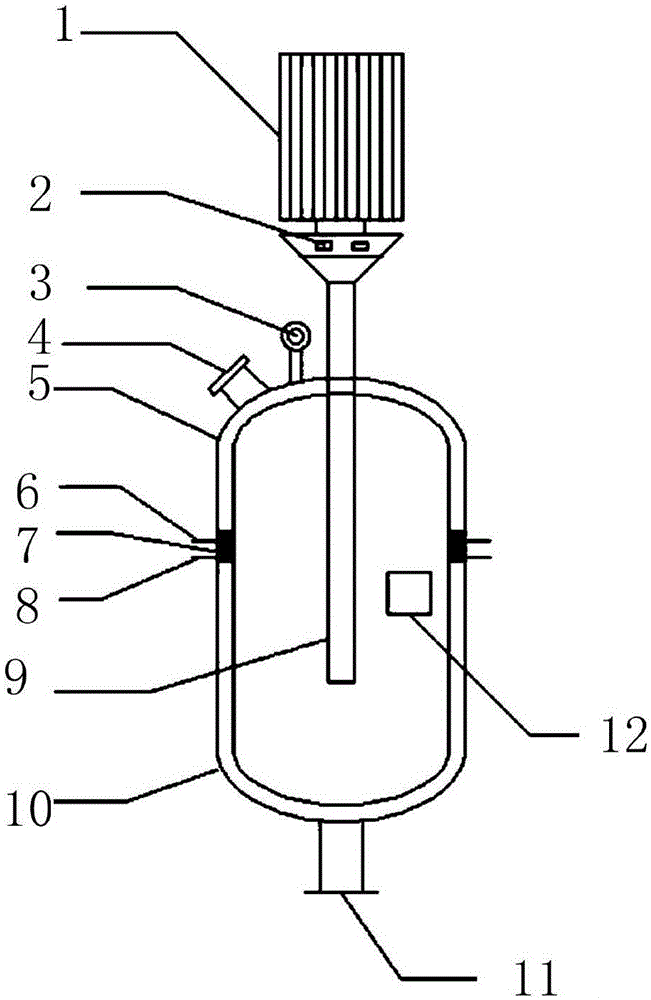

[0026] like figure 1 As shown, a reactor includes an upper reactor body 5, an upper partition 6, a lower reactor body 10, a lower partition 8, a stirring rod 9, a temperature and pressure control system 3, an explosion-proof motor 1, and a reducer 2. The inner wall of the upper reactor body 5 is provided with an upper partition 6 that fits the inner wall, and the upper reactor body 5 is provided with a feed port 4 and an observation port 12; Between the body 5 and the lower reactor body 10, the upper and lower parts of the flanging are provided with a sealing rubber pad 7, and the partition is fixed on the reactor body through the flanging; the lower reactor body 10 and the upper reactor body 5 are connected by hinges, and the lower The reaction kettle body 10 is provided with a discharge port 11, and the lower reaction kettle body 10 is provided with a lower partition 8; the upper part of the lower partition 8 is flanged, and the upper and lower parts of the two flanges are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com