Method for detecting metal defect and method for forming detection structure

A metal defect and detection structure technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of difficulty in addressing physical defects, time-consuming search for the physical location of metal defects, etc., and achieve high detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

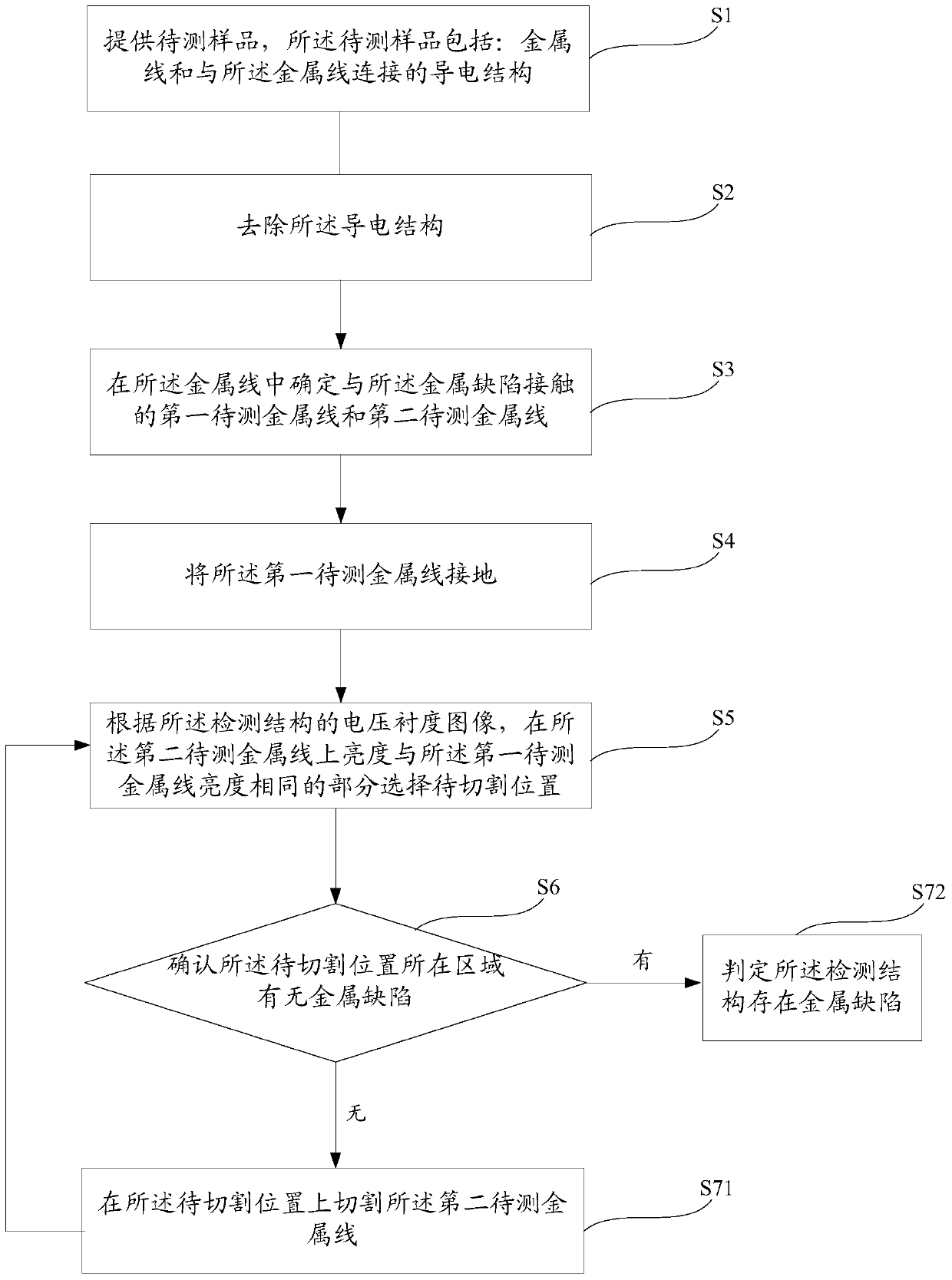

[0031] Such as figure 1 As shown, the embodiment of the present invention provides a method for forming a metal defect detection structure, including:

[0032] Step S1: providing a sample to be tested, the sample to be tested includes: a metal wire and a conductive structure connected to the metal wire;

[0033] Step S2: removing the conductive structure;

[0034] Step S3: determining a first metal line to be tested and a second metal line to be tested in contact with the metal defect among the metal lines;

[0035] Step S4: grounding the first metal wire to be tested.

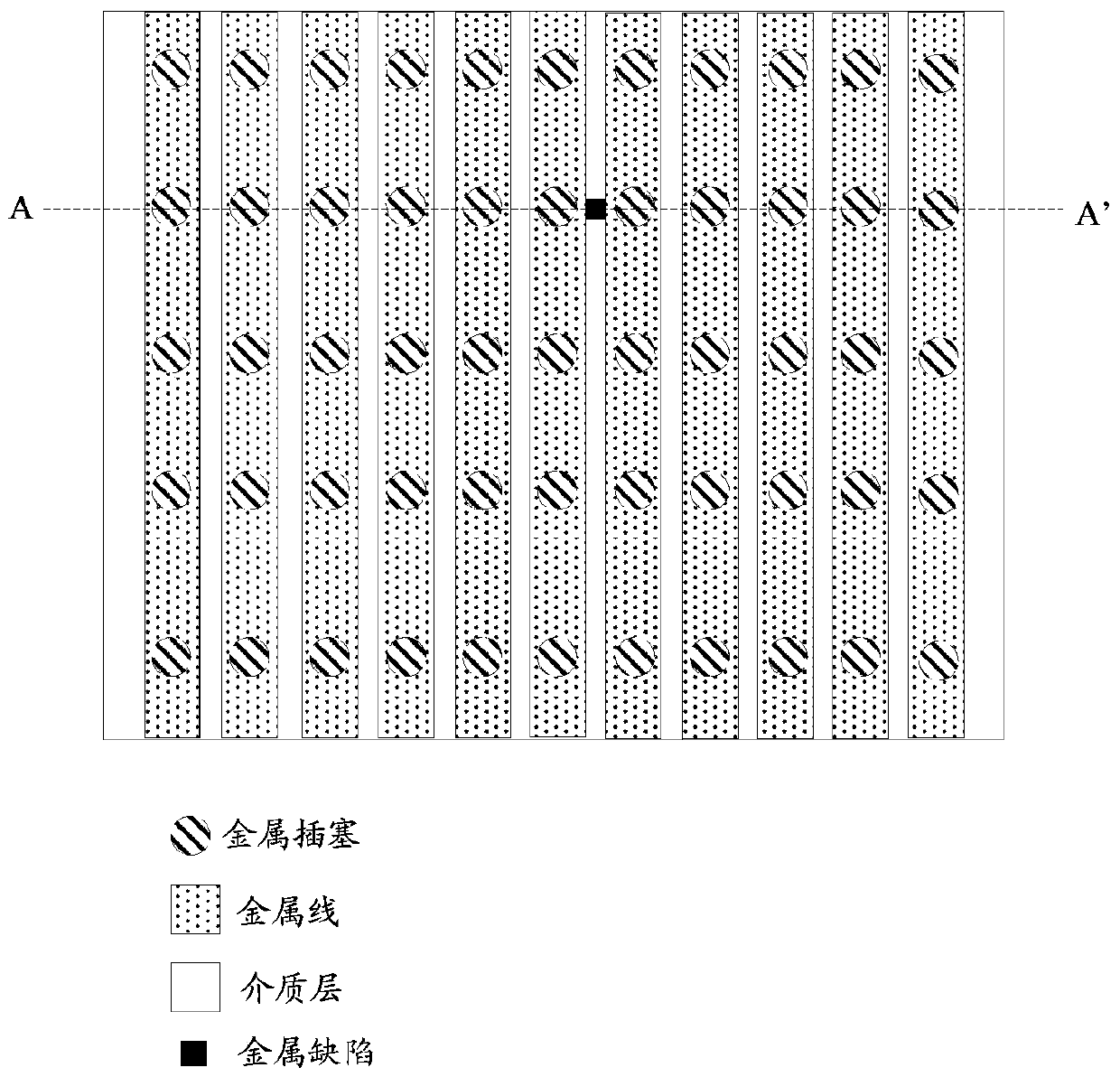

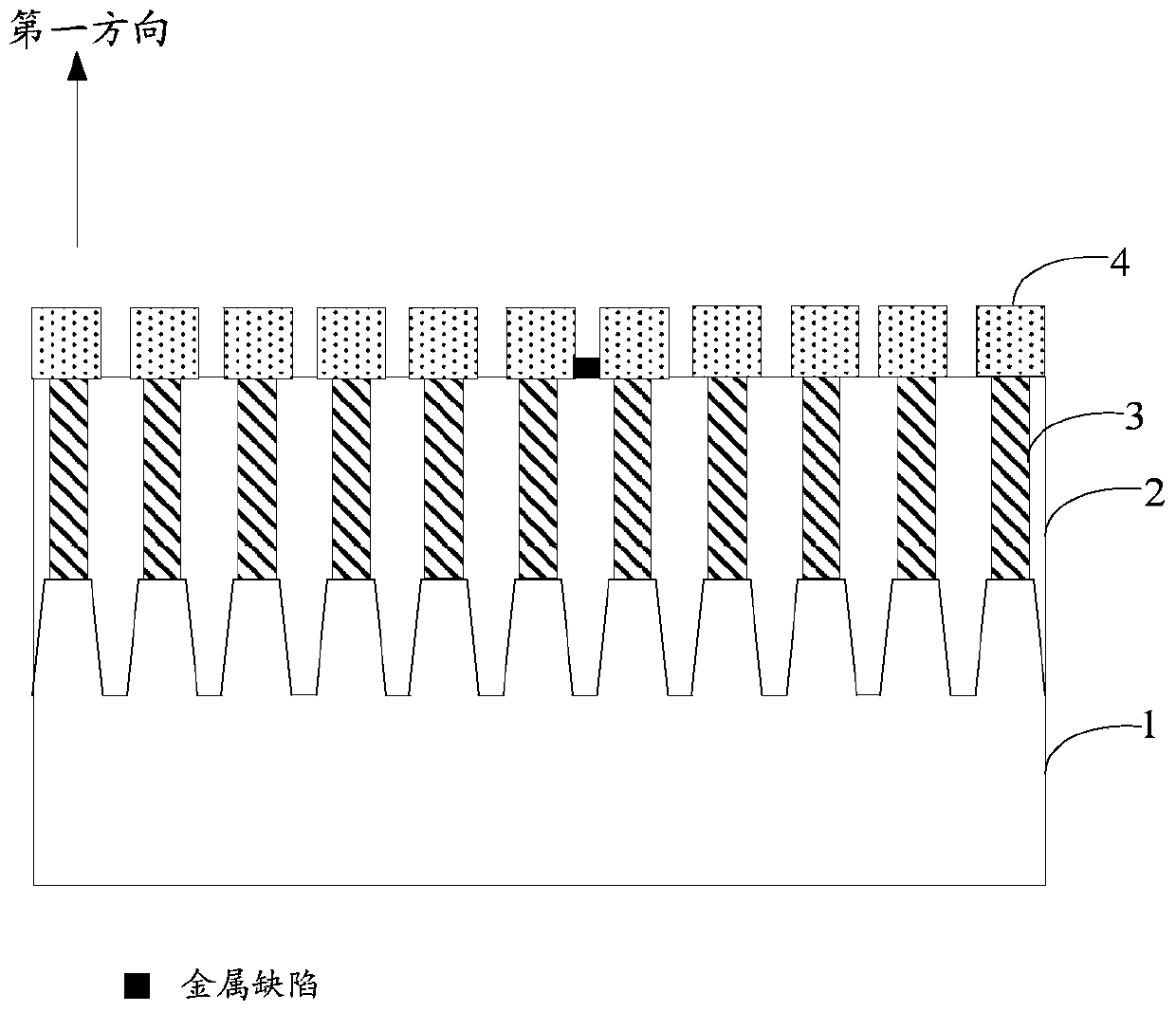

[0036] As a specific embodiment, the conductive structure may include: a metal plug, and the sample to be tested may also include: a substrate and a dielectric layer; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap