Multi-vision defect detecting equipment and method for large-size LCD glass substrate in production line

A glass substrate and defect detection technology, which is used in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of inconvenient storage and query of detection data, poor working environment, and low detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be described in further detail below in conjunction with specific examples and accompanying drawings.

[0071] Aiming at the deficiencies of the existing detection technology, the invention provides a multi-visual defect detection device and method for large-size LCD glass substrates on a production line.

[0072] A multi-vision defect detection equipment for large-size LCD glass substrates on a production line, including an imaging detection system and a bus control system;

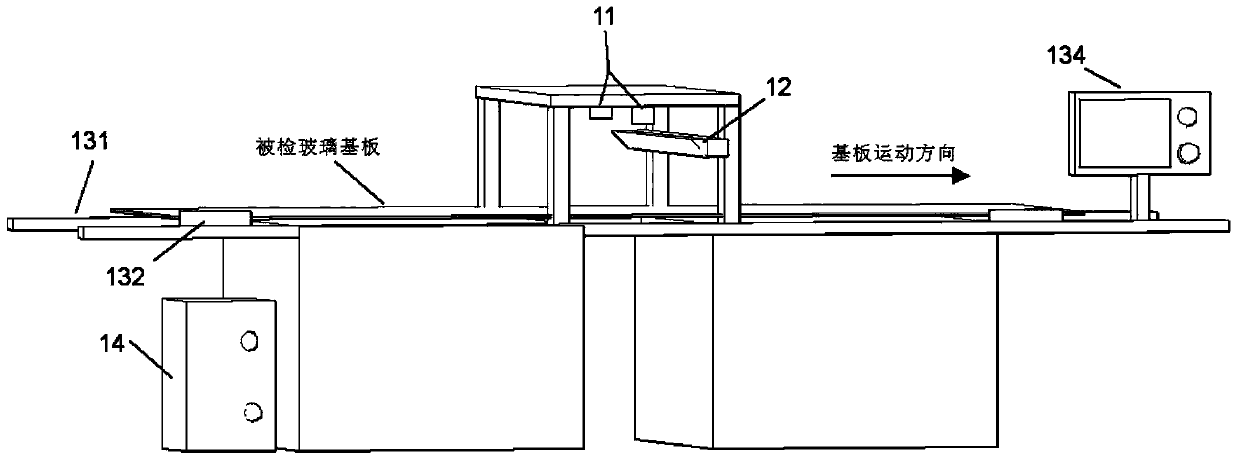

[0073] Wherein, the imaging detection system includes at least two line scan cameras 11 installed side by side, one or more LED line light sources 12, a transmission control device 13 and a detection computer 14;

[0074] The transmission control device 13 includes a conveyor belt 131, a contact sensor 132, a PLC 133 and a PLC interactive display unit 134;

[0075] The touch sensor 132, the PLC 133 and the PLC interactive display unit 134 are connected in sequence; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com