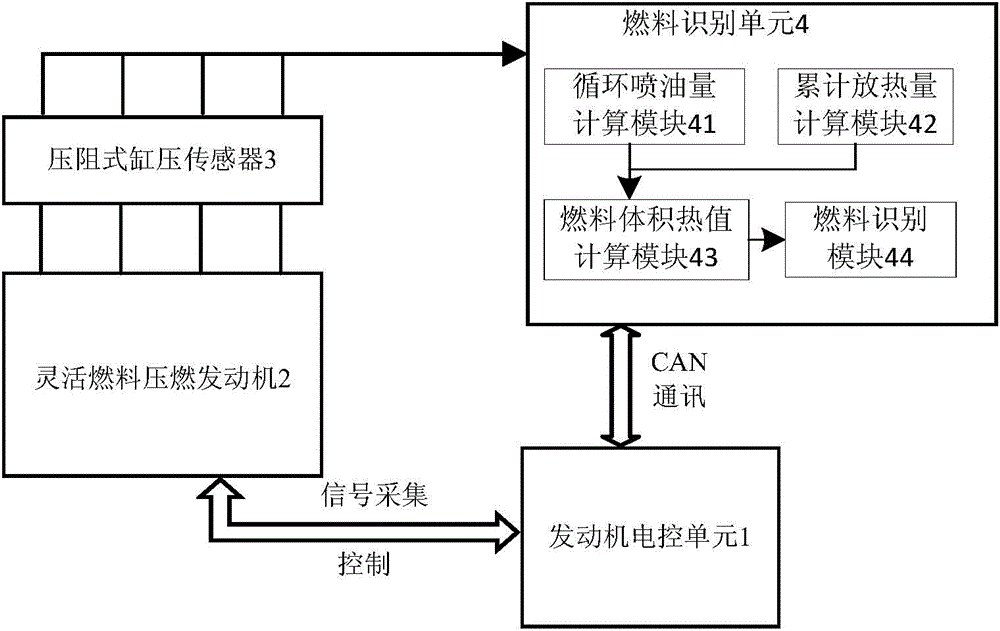

Fuel on-line detection method of gasoline and diesel oil mixing flexible fuel engine

A technology of flexible fuel and detection method, which is applied in engine control, machine/engine, material heat development, etc., and can solve problems such as lack of fuel detection and adaptive control capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

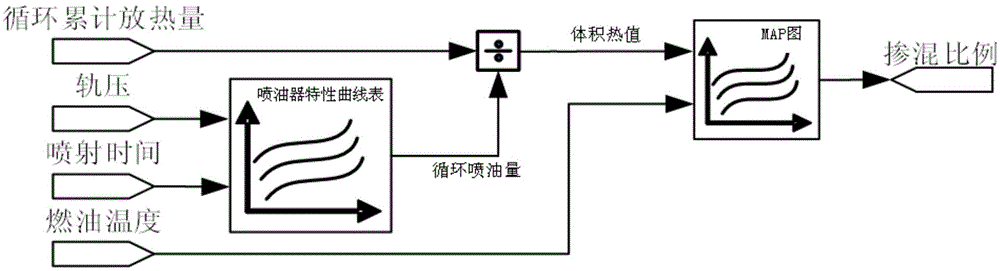

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

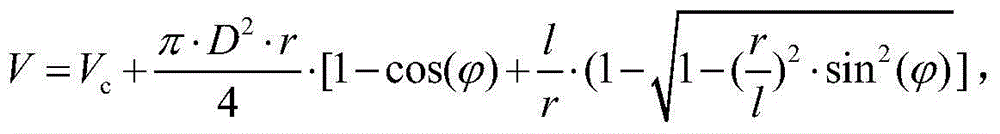

[0036] The heat release of fuel depends on the volume calorific value and volume of the fuel, that is, the product of volume calorific value and volume is the heat release of fuel. In the control system of the engine, if the combustion efficiency is assumed to be 100%, and the difference in the flow characteristics of the injector to different fuels is ignored, the cumulative heat release of the cycle depends entirely on the amount of cycled fuel injection and the volumetric calorific value of the fuel. Wherein, the cycle fuel injection quantity is related to injection pressure and injection time, that is to say, when the injection pressure and injection time are determined, the cycle fuel injection volume is determined for a specific fuel. Therefore, we are more concerned about the difference in the volumetric calorific value (the heat contained in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com