Device for measuring contact force of foot of human body

A measuring device and contact force technology, applied in the directions of diagnostic recording/measurement, medical science, diagnosis, etc., can solve the problems that the pressure sensor cannot contact the force information effectively, and the force measuring insole is expensive, so as to ensure the wearing comfort and reduce the cost. Small loss, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

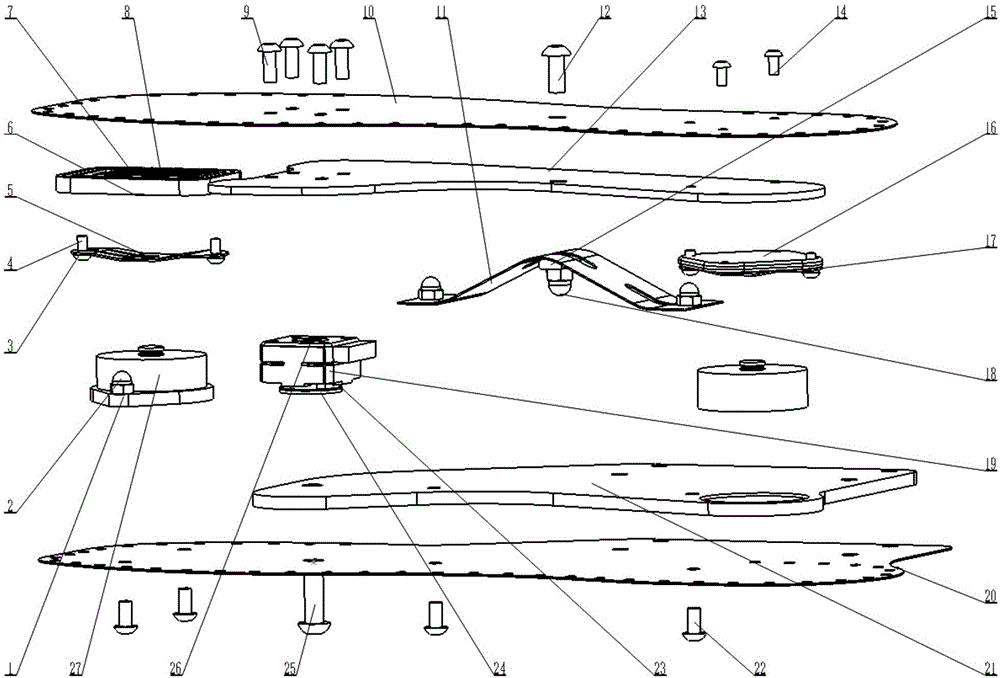

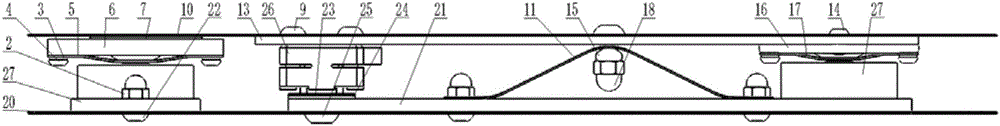

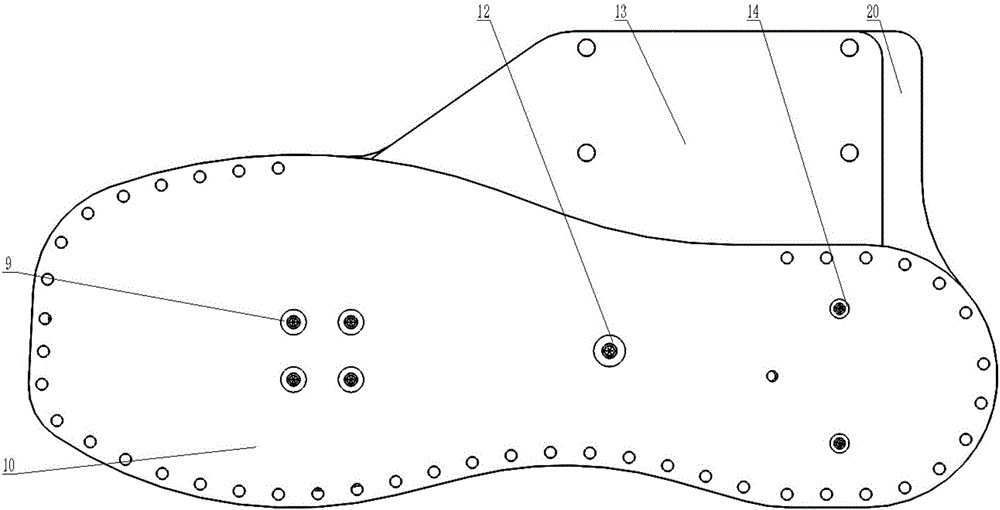

[0024] Specific implementation mode one: as Figure 1~4 As shown, the human foot end contact force measuring device of this embodiment includes a CM base 1, a front CM card slot 5, a needle row groove 6, a needle row 7, a roller row gasket 8, a top steel plate 10, and a tension spring Sheet 11, top carbon plate 13, CM cover plate 16, rear CM card slot 17, three-dimensional force sensor 19, bottom steel plate 20, bottom carbon plate 21 and two one-dimensional force sensors 27; bottom carbon plate 21 is fixed on the bottom steel plate 20, the top carbon plate 13 is fixed on the lower end surface of the top steel plate 10, a three-dimensional force sensor 19 and two one-dimensional force sensors 27 are arranged between the bottom steel plate 20 and the top steel plate 10, and the three-dimensional force sensor 19 is located at Below the sole of the forefoot, one of the two one-dimensional force sensors 27 is fixed on the upper end surface of the bottom steel plate 20 through the ...

specific Embodiment approach 2

[0029] Specific implementation mode two: as Figure 1~2 As shown, one of the two one-dimensional force sensors 27 in this embodiment is fixed on the bottom steel plate 20 through the M4 semi-cylindrical hexagon head cap nut 2 and the M4×8 hexagon socket head cap screw 22 . Such a design makes the one-dimensional force sensor stronger when subjected to impact loads. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: as figure 1 , figure 2 with image 3 As shown, the tension reed 11 of this embodiment is fixedly connected to the upper and lower steel plate structures through M5×12 hexagon socket head cap screws 12, semicircular nuts 15 and M5 semicylindrical hexagon head cap nuts 18. Such a design can prevent the upper steel plate from collapsing. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com