Mechanical sampling spoon

A technology of mechanical sampling and sampling spoons, applied in the direction of small shovels, etc., can solve the problems of high requirements on weighing accuracy, difficult to control the amount of finger force, excessive addition, etc., to ensure accuracy and reliability, and reduce human factors. Interference, the effect of ensuring quality accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

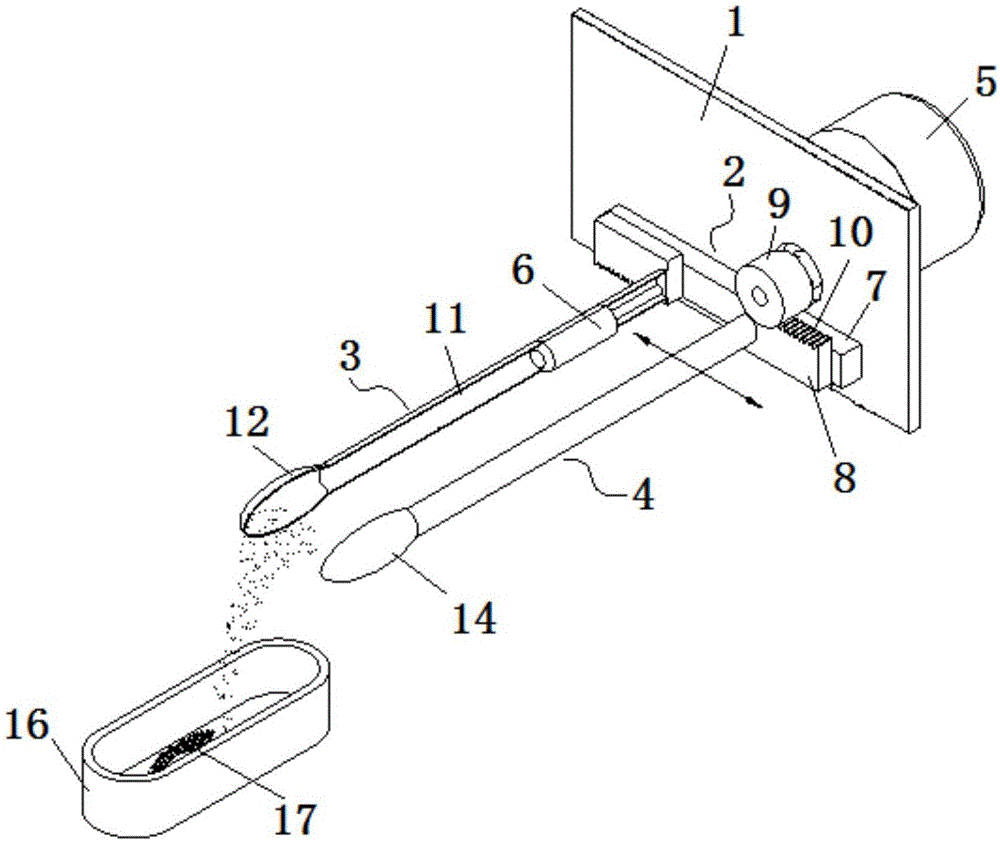

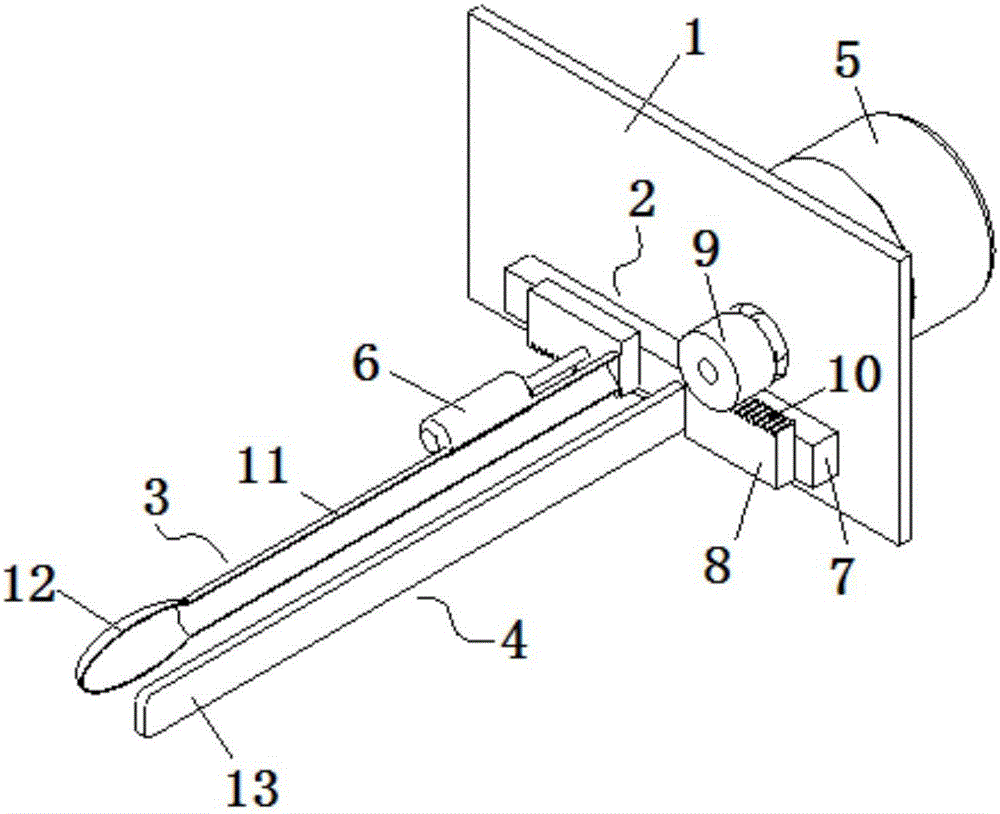

[0023] Such as figure 1 As shown, the device of the present invention includes a fixed plate 1, a guide mechanism 2 is fastened to one side end surface of the fixed plate 1, and a relatively sliding sampling spoon 3 and an auxiliary sampling cover 4 are arranged on the guide mechanism 2, and the auxiliary sampling cover 4 It is used to close the sampling spoon 3; a driving device 5 is provided on the other end surface of the fixed plate 1, and the driving device 5 is used to control the sliding of the sampling spoon 3 and / or the auxiliary sampling cover 4.

[0024] In order to shake off the sample stained on the outer wall of the sampling spoon 1 and to ensure that the samples in the sampling spoon 1 are dropped evenly and reliably, a vibrator 6 can be arranged on the sampling spoon 1 and / or the auxiliary sampling cover 4 .

[0025] Wherein, the guide mechanism 2 includes a slide rail 7 fastened to one side end surface of the fixed plate 1 and arranged horizontally, and the sa...

Embodiment 2

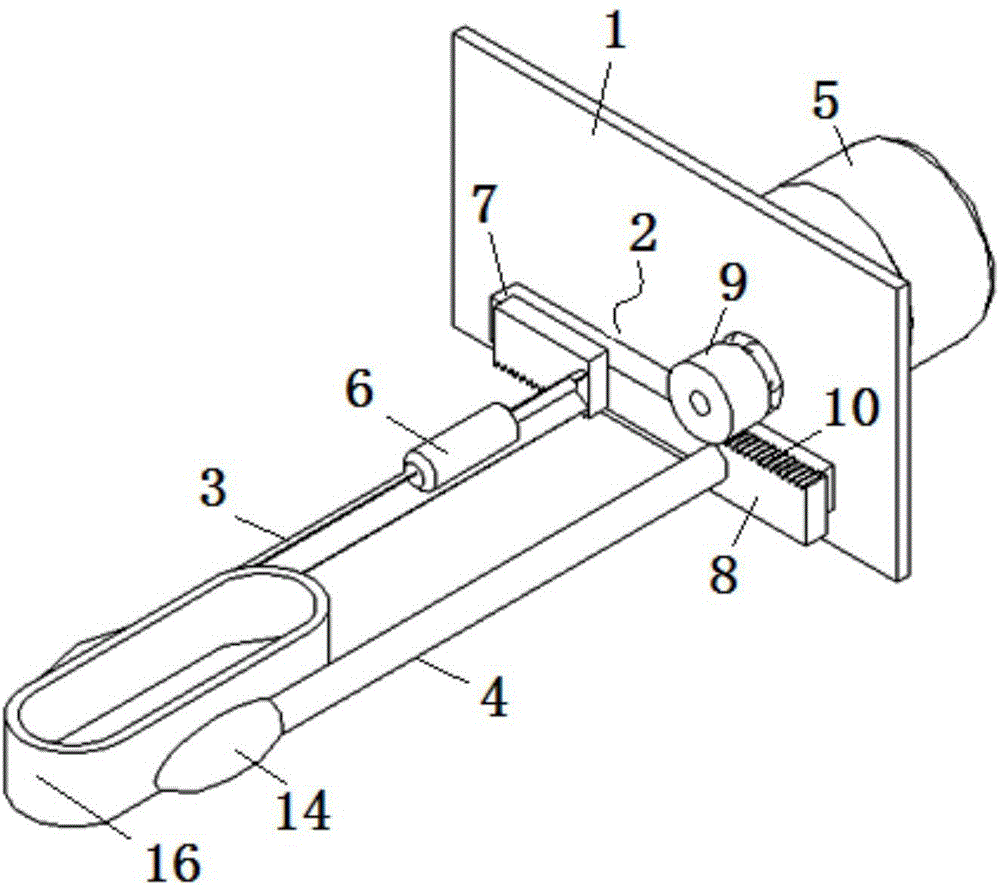

[0036] For the sake of brevity, in the description of this embodiment, the same technical features as those of Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

[0037] Such as Figure 4 As shown, the guide mechanism 2 includes a horizontally arranged fixed block fastened on one side of the fixed plate 1, and a guide groove 15 penetrating the fixed plate 1, a sampling spoon 3 and / or an auxiliary sampling cover are provided on the fixed block. 4 is slidably inserted in the guide groove 15, and the sampling spoon 3 and / or the auxiliary sampling cover 4 moves along the length direction of the sampling spoon 3.

[0038] In order to adjust the opening and closing speed and stability between the sampling spoon 3 and the auxiliary sampling cover 4, the driving device 5 can be connected with one end of the sampling spoon 3 and / or the auxiliary sampling cover 4 through a rack and pinion mechanism. The rack is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com