Stamping lower die with adjustable angle

An adjustable and mold technology, applied in the field of stamping processing, can solve the problems of loose mold seat and support block, affecting mold processing accuracy, time-consuming and laborious, etc., to achieve the effect of intuitive adjustment, intuitive and accurate angle, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

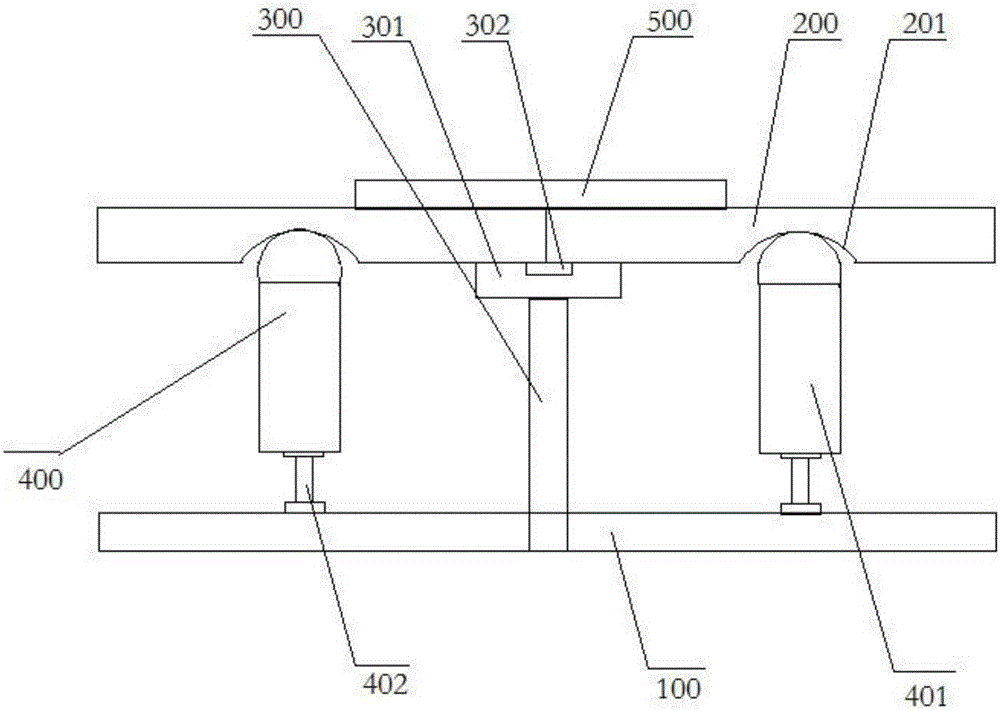

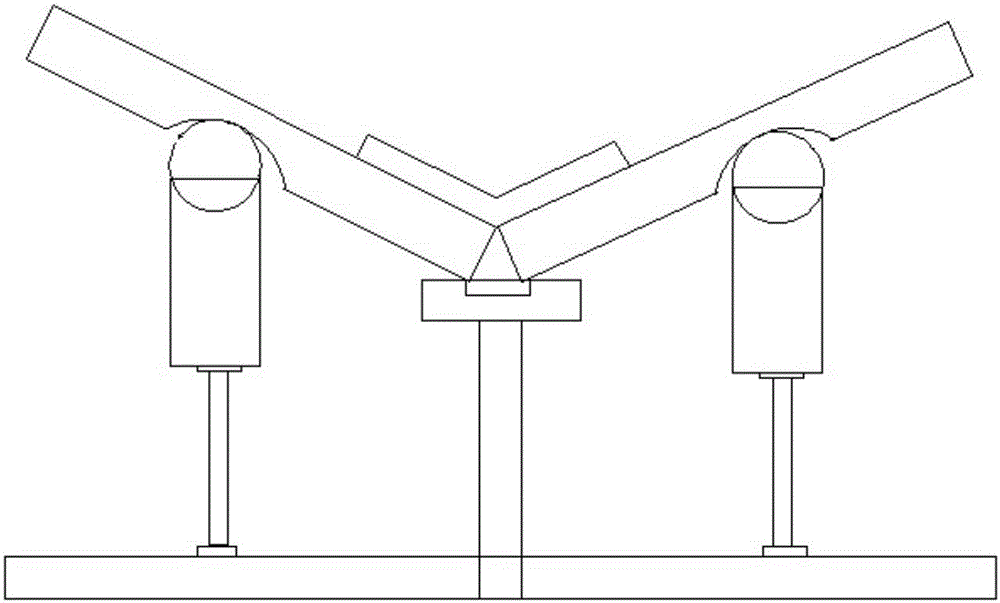

[0024] Such as figure 1 As shown, a stamping lower mold with adjustable angle includes a base 100 arranged horizontally, a central support device 300, two lower molds 200 and a lifting device 400 that are mutually symmetrical and rotatably connected to each other;

[0025] The lower part of the lower mold 200 is provided with symmetrically distributed arc-shaped slots 201;

[0026] The lifting device 200 is arranged between the base 100 and the lower mold 200, and the number of the lifting device 200 is an even number, and the lifting device 400 is symmetrically distributed; the lifting device 400 includes a supporting part 401 and a lifting rod 402 connected in sequence, the lifting rod 402 is an electric control lifting rod; the top of the support part 401 is in the shape of a semi-cylindrical, and its cross-section is semicircular, and its arc is larger than the arc-shaped slot 201, so as to ensure that the support part 401 and the lower mold 200 are connected in a circular...

Embodiment 2

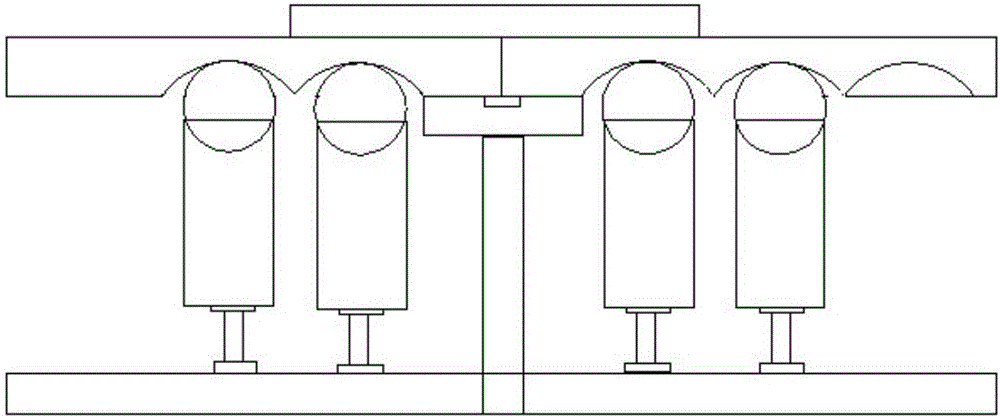

[0031] Such as image 3 As shown, a stamping lower mold with an adjustable angle includes a base 100 arranged horizontally, a central support device 300, two lower molds 200 and a lifting device 400 that are mutually symmetrical and rotatably connected to each other; the bottom of the lower mold 200 The arc-shaped slot 201 is provided with symmetrical distribution; the lifting device 200 is arranged between the base 100 and the lower mold 200, and the number of the lifting device 200 is an even number, and the lifting device 400 is symmetrically distributed; the lifting device 400 includes The supporting part 401 and the elevating rod 402 connected in sequence, the elevating rod 402 is an electric control elevating rod; the top of the supporting part 401 is in the shape of a semi-cylindrical, its cross-section is semicircular, and its radian is larger than that of the arc-shaped slot 201, ensuring the support Part 401 and the lower part of the lower mold 200 are connected in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com