Rolling mechanism of drive shaft of woodworking machine

A technology for a drive shaft and a woodworking machine, which is applied to wood processing appliances, manufacturing tools, circular saws, etc., can solve the problems of complexity, many accessories, and inconvenience, and achieve the effects of small oscillation amplitude, extended service life and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

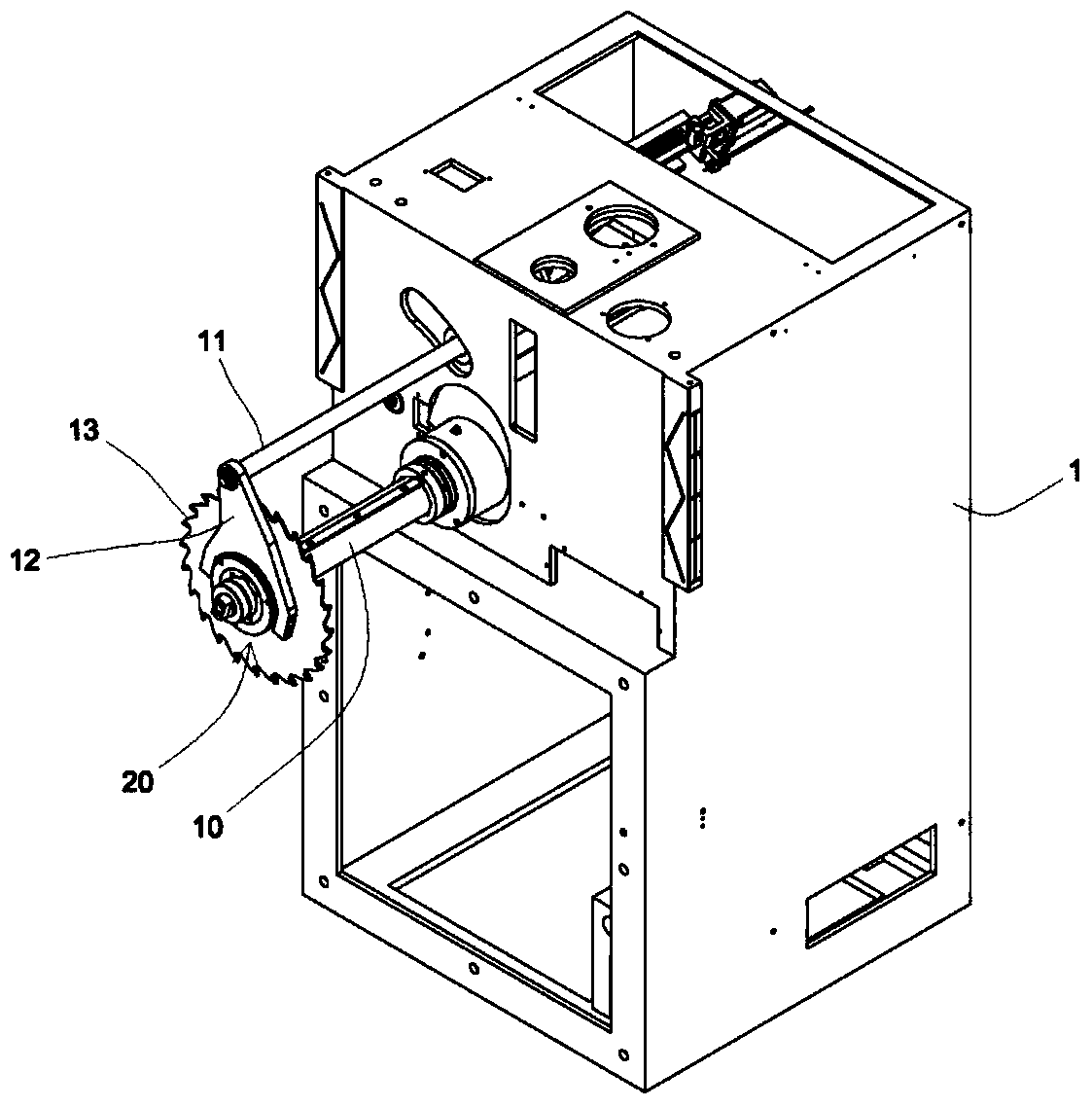

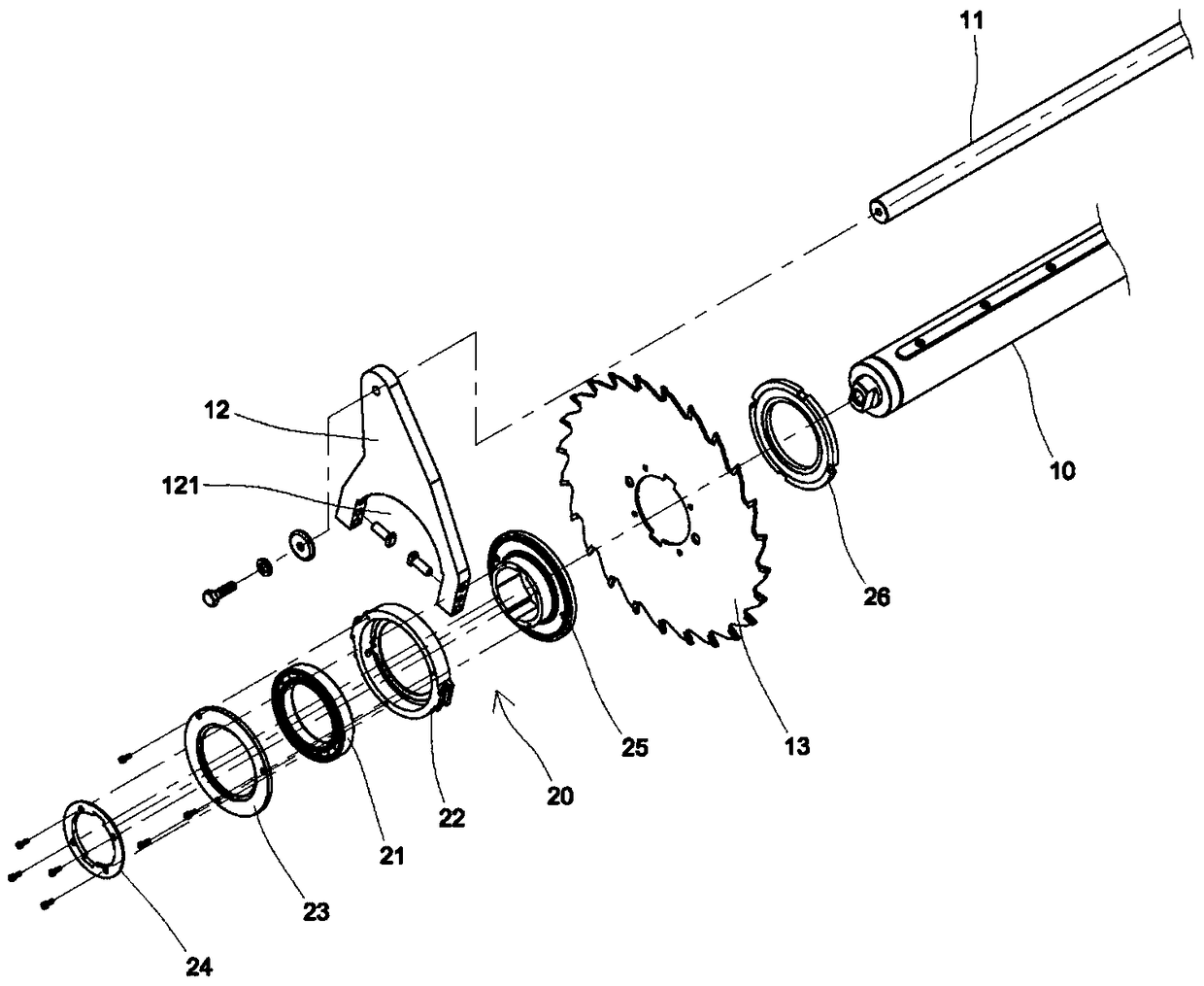

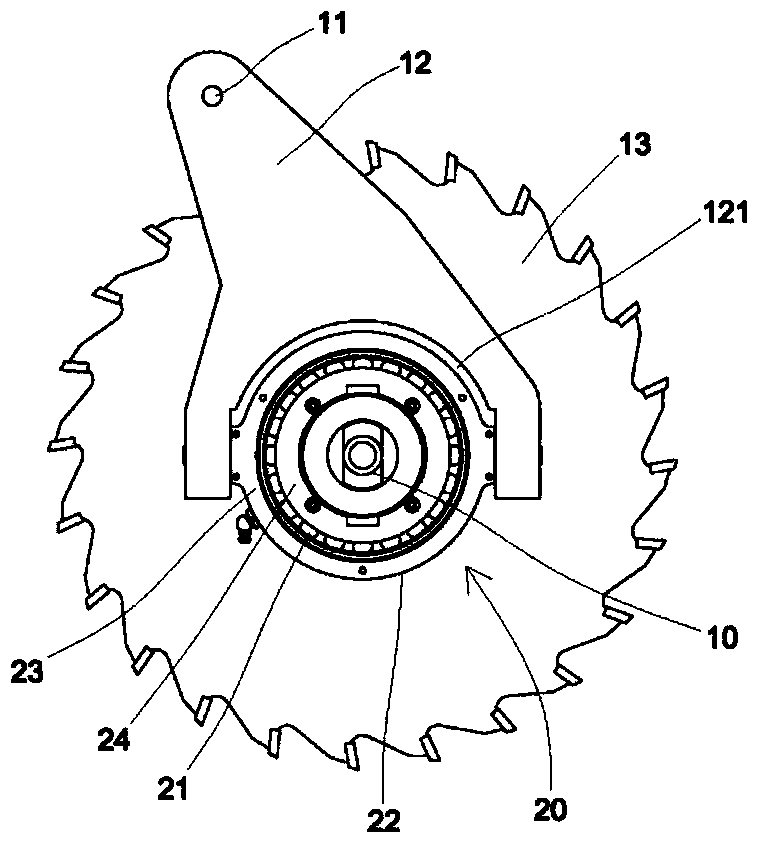

[0038] The present invention is a rolling mechanism of a drive shaft of a woodworking machine, such as Figure 5-8 As shown, a power mechanism (generally a motor, not shown) is assembled in a box body 30, and the power mechanism provides a transmission shaft 400 rotational force, and the transmission shaft 400 protrudes outside the box body 30, and the box body 30 is internally pivoted. Connect a stabilizing bar 31, and the stabilizing bar 31 also protrudes outside the casing 30. The stabilizing bar 31 locates a stabilizing plate 32. The stabilizing plate 32 is slightly triangular. A rolling mechanism 40 is connected, and the rolling mechanism 40 is connected to at least one saw blade 43 and a transmission shaft 400. The rolling mechanism 40 includes:

[0039] Two plates 41, the plates 41 are pivotally connected to the two ends of the tiger's mouth 321, the plate 41 is a circular piece, the two ends of the tiger's mouth 321 are pivotally connected with the rivets 411 as the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com