Pile turning machine

A technology of turning and throwing, which is applied in the field of turning and can solve the problems of poor turning and throwing effect and mutual collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

[0013] Below in conjunction with accompanying drawing, technical solution of the present invention is described in further detail:

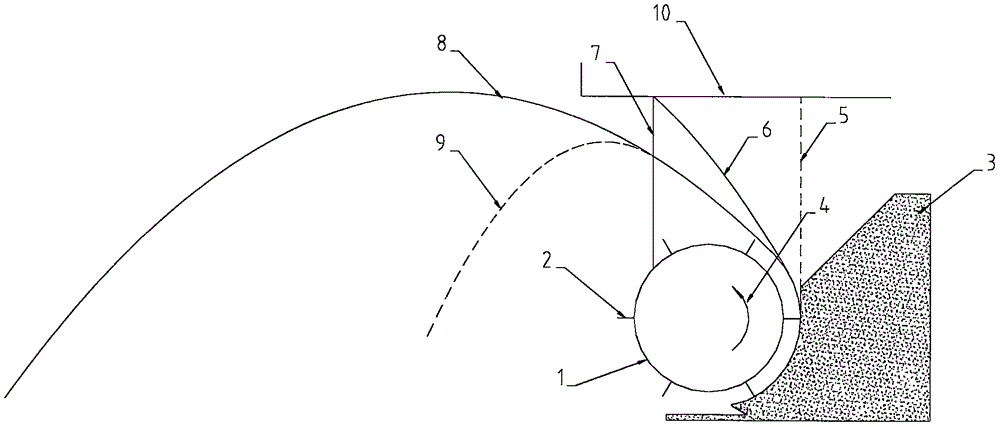

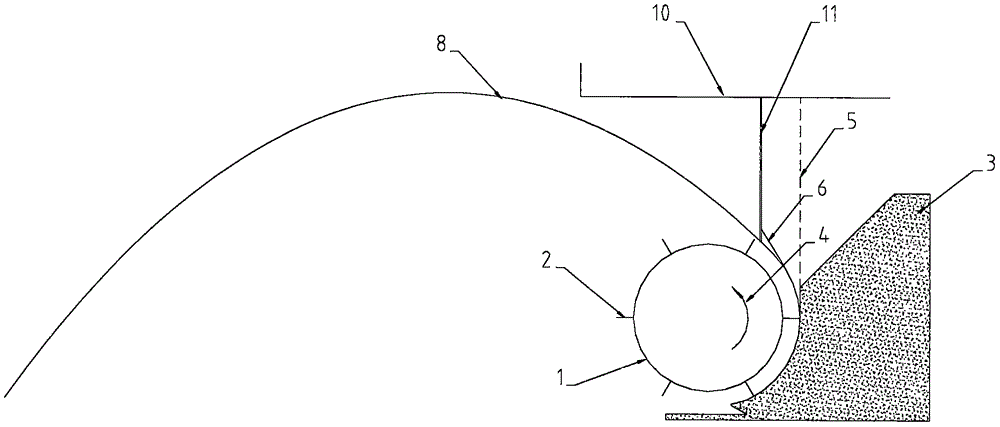

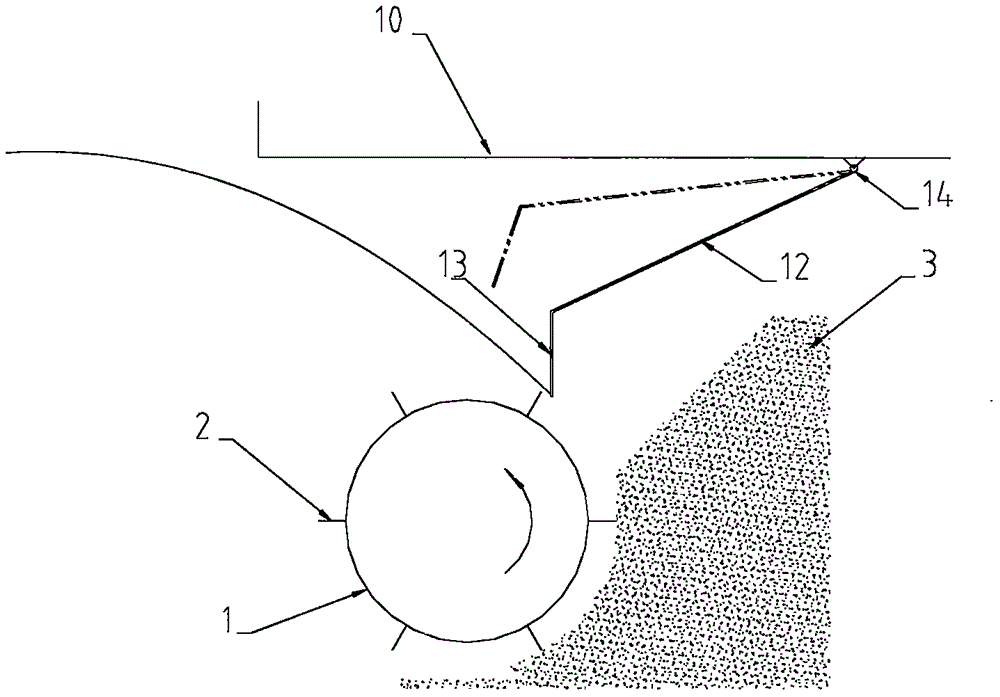

[0014] The process of turning and throwing sludge with traditional compost turners is as follows: figure 1 As shown, the drum (1) rotates counterclockwise, so that the front soil (3) is scooped up and thrown out. The direction in which the soil is thrown is affected by the depth of the drum buried in the soil. When the buried depth is shallow, it is thrown forward, otherwise it is thrown backward. Now define the vertical upward flight path (5) of the soil as the forward and backward throwing to the dividing line, and then the throwing angle is the angle between the front and rear throwing to the left side of the dividing line (5) and the horizontal direction. The soil with a large throwing angle moves along the high-throwing flight route (6), and will hit the bottom of the vehicle (10) due to the structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com