Detection-diagnosis device and method for vibration fault of aeroengine

A technology for aero-engines and faults, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems that the engine cannot be installed, affects the results of vibration analysis and diagnosis, and cannot guide the on-site vibration test and vibration elimination process, etc., to achieve The effect of improving the qualification rate and vibration elimination success rate and improving the level of vibration analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

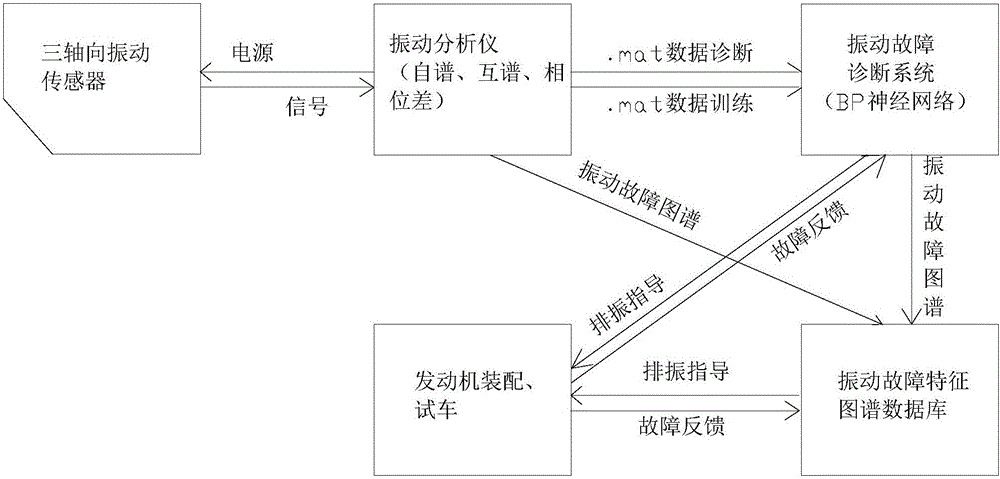

[0032] A device for detecting and diagnosing vibration faults of aero-engines, such as figure 1 shown, including:

[0033] Three-axis vibration sensor: installed on the case of a faulty aero-engine with vibration exceeding the standard, to measure horizontal, vertical and axial vibrations; in this embodiment, the B&K4321V three-axis vibration sensor is selected, which has good stability and high reliability. Internal integrated ICP circuit, single screw installation, suitable for production site use. B&K 4321V three-axis vibration sensor X, Y, Z respectively measure the vibration acceleration signals of the horizontal, vertical and axial directions of the aero-engine.

[0034] Vibration analyzer: supplies power to the three-axis vibration sensor and detects vibration fault signals; obtains the vibration fault characteristic ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com