Angular-contact ball-bearing radial static stiffness measurement apparatus

A technology of angular contact ball bearing and measuring device, applied in the direction of mechanical bearing testing, etc., can solve the problems of first-order critical speed reduction, resonance failure, affecting the normal operation of the engine, etc., to achieve the effect of increasing accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

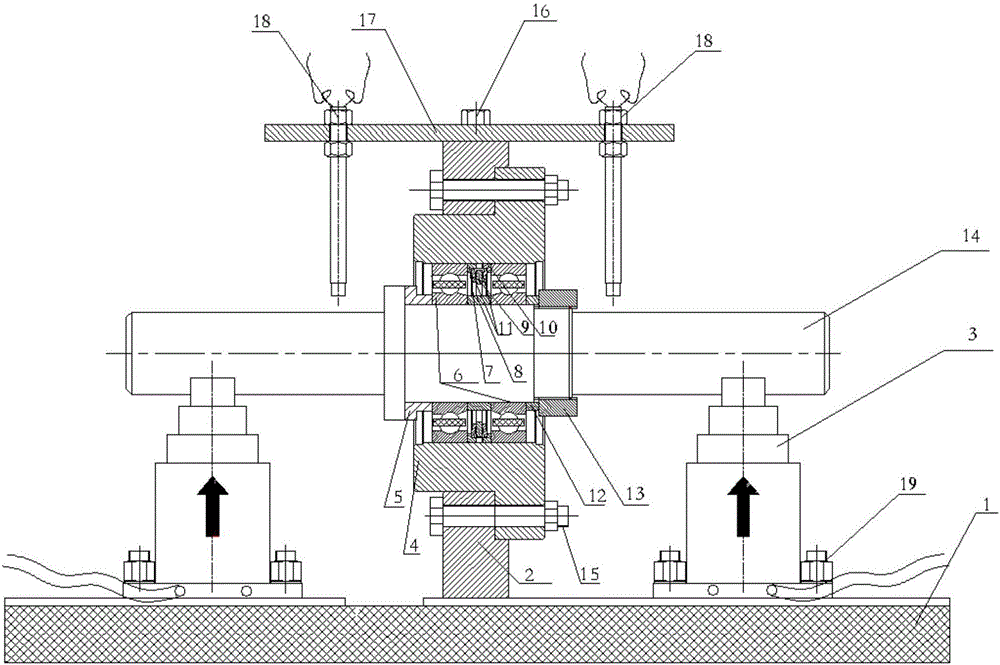

[0020] Such as figure 1 As shown, the angular contact ball bearing radial static stiffness measuring device of the present invention includes a base 1, a bracket 2, two hydraulic boosters 3, an adapter sleeve 4, an adjustment pad I5, a stop plate I7, and an adjustment pad between bearings 8. Disc spring spacer 9, baffle plate II10, two disc springs 11, adjusting pad II12, tightening nut 13, force shaft 14, twelve bolts and nuts I15, bolts 16, pressure plate 17, two eddy current sensors 18 , eight bolts and nuts II19; the test objects are: two bearings 6.

[0021] The bracket 2 is vertically fixed on the base 1 by four long bolts, and the adapter sleeve 4 and the bracket 2 are fastened in a circumferential circle by twelve bolts and nuts I15; the adjustment pad I5, the left bearing 6, and the retaining plate I7 , Disc spring 11 on the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com