Spring actuators for closing elements of motor vehicles

A technology for closing elements, actuators, applied in the direction of springs/shock absorbers, springs, coil springs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

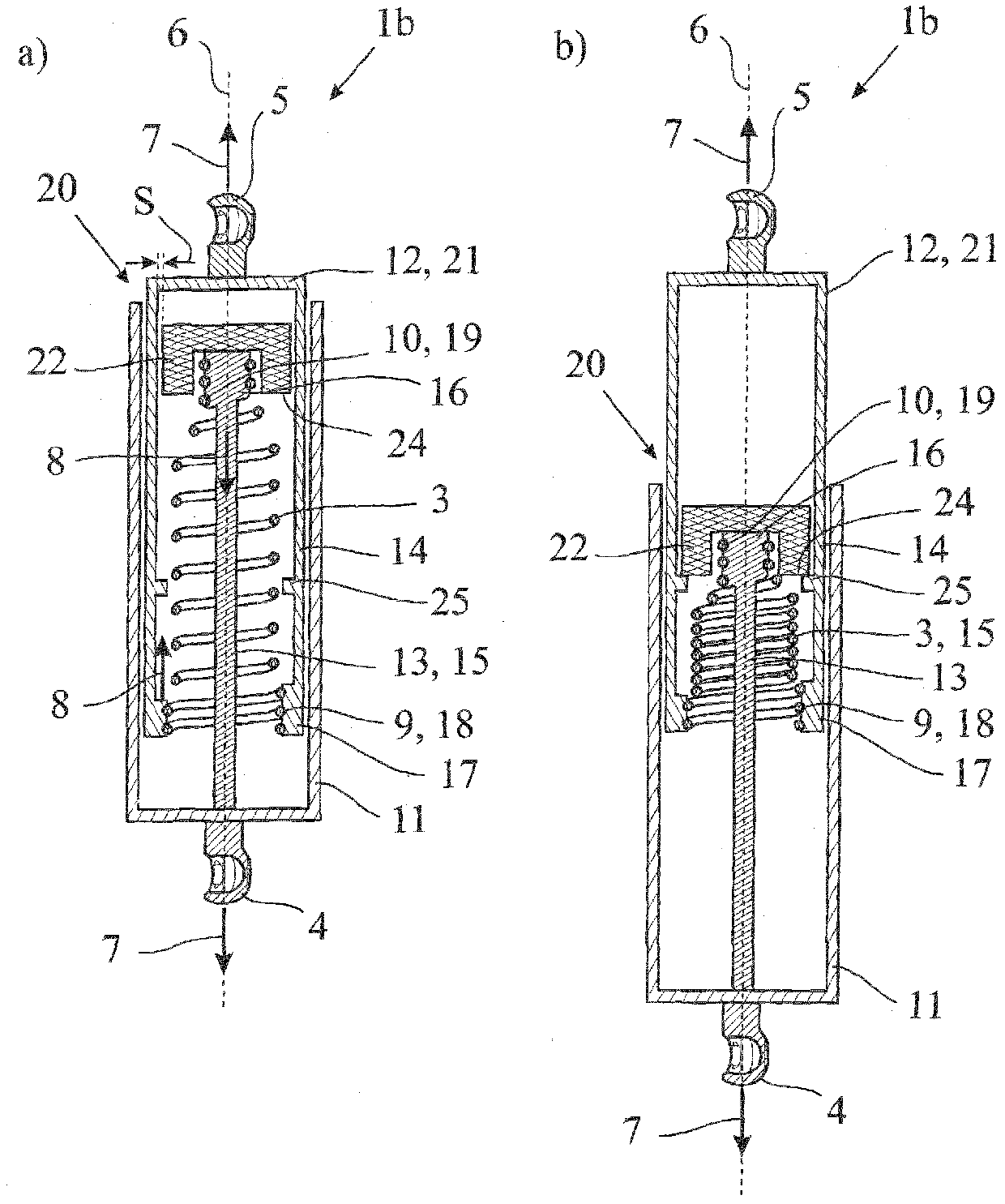

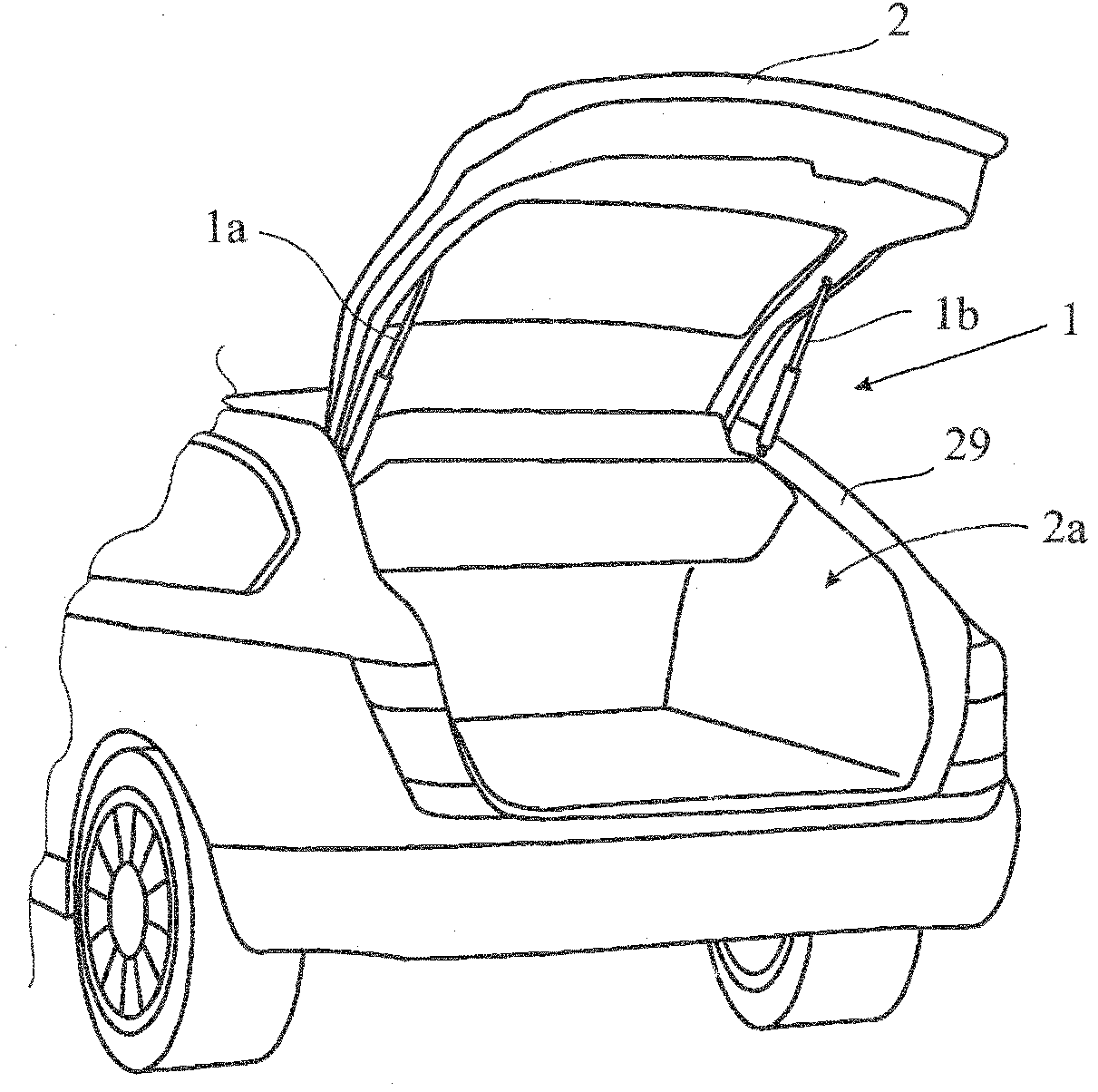

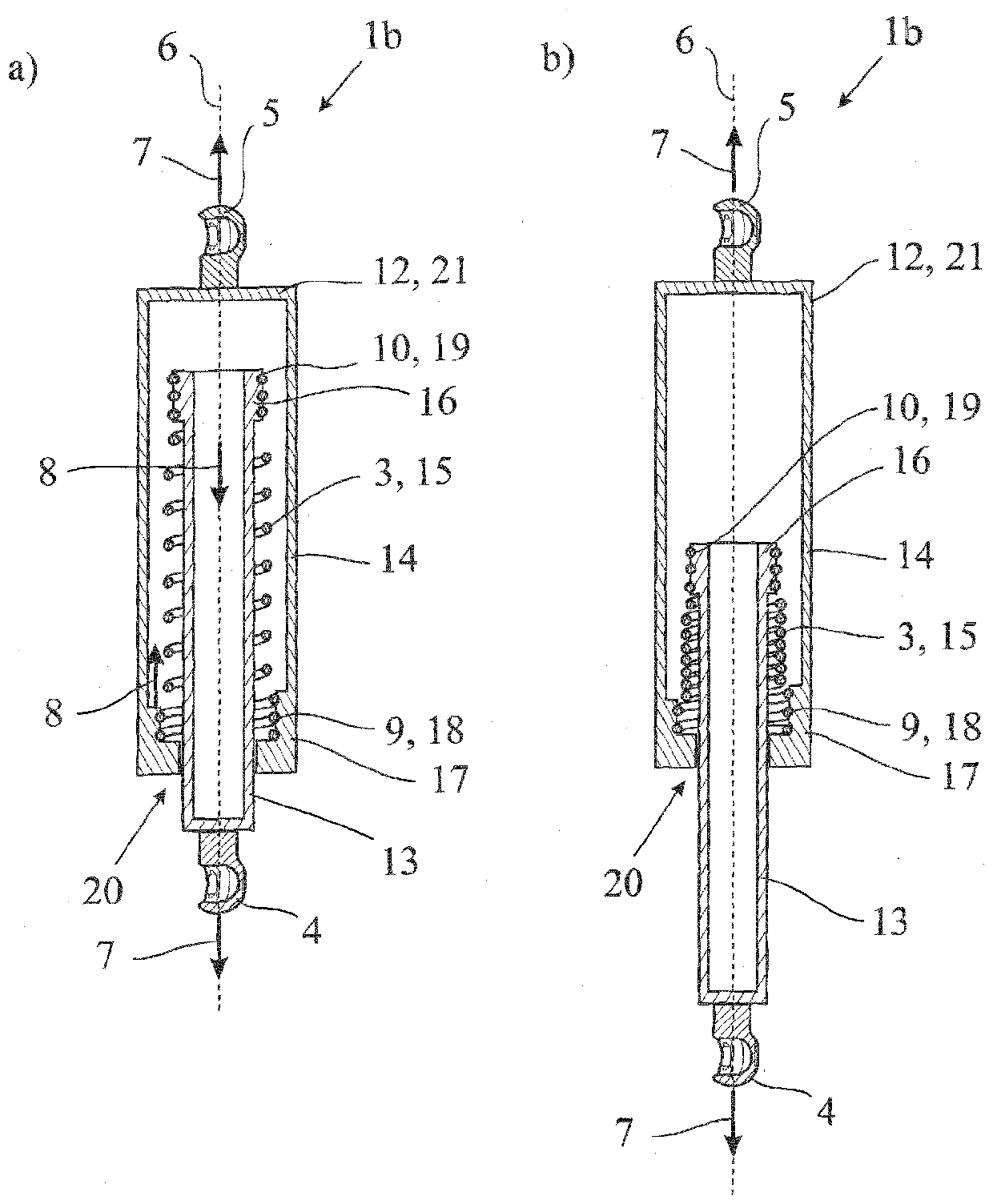

[0025] in figure 1 The drive mechanism 1 shown in FIG. 1 has a motor-driven driver 1a shown on the left and a spring driver 1b shown on the right. The driving mechanism 1 is used for motor-driven displacement of a tailgate 2 of a motor vehicle. However, all other closing elements mentioned in the preamble of the description can also be used advantageously. All the following embodiments with regard to the tailgate apply correspondingly to all other closing elements that can be considered.

[0026] The spring driver 1b here provides support for the closing element 2 in terms of its gravity. The spring driver is equipped with a spring mechanism 3 that provides a driving force for the spring driver 1b.

[0027] The spring driver 1b has a first driver joint 4 and a second driver joint 5 which can be displaced relative to each other along the geometric longitudinal axis 6 of the spring driver 1b and they are here and preferably arranged on the geometric longitudinal axis 6. This can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com