Split type guide plate for accurately positioning orthodontic bracket

An orthodontic bracket and precise positioning technology, applied in brackets, orthodontics, medical science, etc., to achieve precise positioning, one-time bonding, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

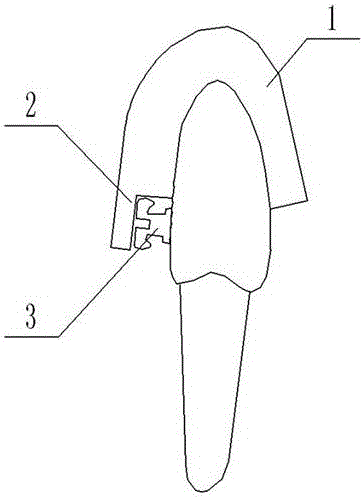

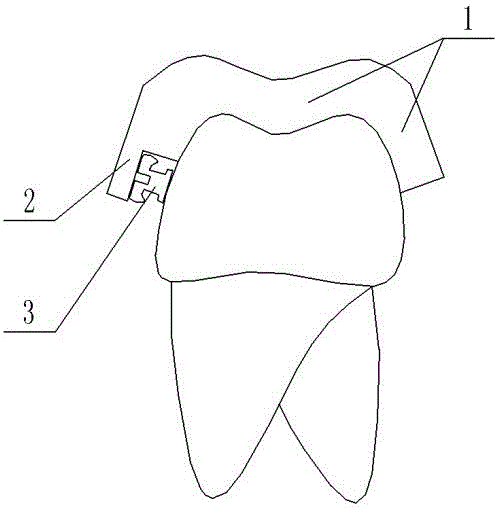

[0023] Embodiment 1: as figure 1 , figure 2 As shown, a split guide plate for precise positioning of orthodontic brackets includes an anastomotic part 1 and a buccal groove 2. The anastomotic part 1 is arranged on the crown of the tooth and surrounds the occlusal surface of the teeth, Part of the lip and buccal surface, part of the lingual surface, and coincides with the tooth body. The buccal groove 2 is located on the lip and buccal side of the anastomosis of the teeth. The inner surface of the buccal groove 2 and the orthodontic bracket 3 Occlusal side anastomosis.

[0024] The height of the buccal groove 2 is consistent with the height of the planned orthodontic bracket 3 , and the buccal groove 2 is used for accommodating and positioning the bracket. The guide plate is made individually for a single tooth, the outer side of the buccal groove 2 is open, and the guide plate is made of a transparent material.

[0025] The guide plate is a 3D printing split guide plate. ...

Embodiment 2

[0033] Embodiment 2: as figure 1 , figure 2 As shown, a split guide plate for precise positioning of orthodontic brackets includes an anastomotic part 1 and a buccal groove 2. The anastomotic part 1 is arranged on the crown of the tooth and surrounds the occlusal surface of the teeth, Part of the lip and buccal surface, part of the lingual surface, and coincides with the tooth body. The buccal groove 2 is located on the lip and buccal side of the anastomotic part 1 of the teeth. The inner surface of the buccal groove 2 and the orthodontic bracket 3 The side of the occlusal side is anastomosed.

[0034] The height of the buccal groove 2 is consistent with the height of the planned orthodontic bracket 3 , and the buccal groove 2 is used for accommodating and positioning the bracket. The guide plate is made individually for a single tooth, the outer side of the buccal groove 2 is open, and the guide plate is made of a transparent material.

[0035] The guide plate is a 3D pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com