A steel pipe bending device with electromagnetic heating function

A bending device and bending technology, applied in the field of steel pipe bending machinery design, can solve the problems of wrong steel pipe bending size, increase labor intensity, and reduce labor efficiency, so as to improve bending accuracy, reduce self-stress, and widely The effect of using range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

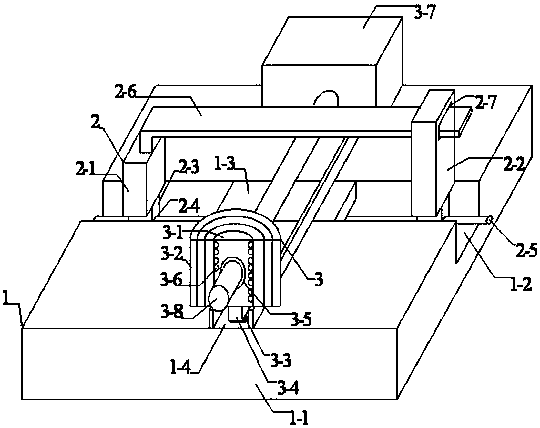

[0015] Referring to the accompanying drawings, by describing the embodiments, the specific implementation of the present invention, such as the shape and structure of each component involved, the mutual position and connection relationship between each part, the role and working principle of each part, etc. Further details.

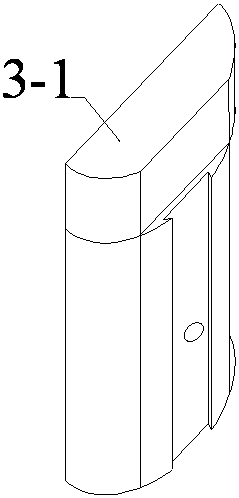

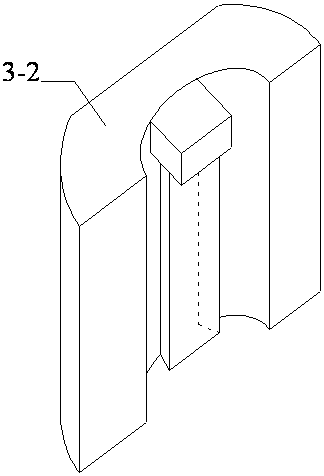

[0016] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a steel pipe bending device with electromagnetic heating function, including a bending support system 1, a level adjustment system 2 and a heating bending system 3, and the level adjustment system 2 and the heating bending system 3 are fixed on the bending On the folding support system 1, the bending support system 1 includes a support base 1-1, a horizontal adjustment groove 1-2, a transition bridge 1-3 and a bending slideway 1-4, and the horizontal adjustment groove 1-2 is arranged on the support base 1 -1, the transition bridge 1-3 is set at the upper end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com