Shoal well site well drilling assisting platform

An auxiliary platform and well site technology, applied in the direction of roads, special pavements, roads, etc., can solve problems such as poor wood bearing capacity, and achieve the effect of normal connection function, high reliability and good reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

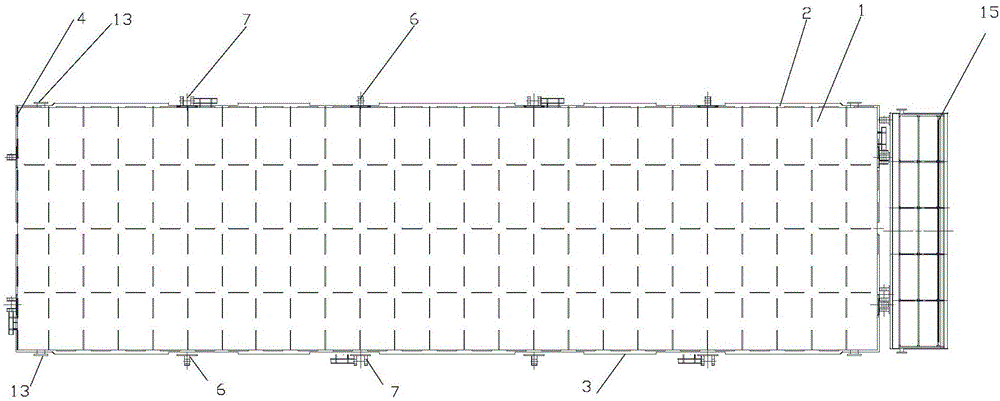

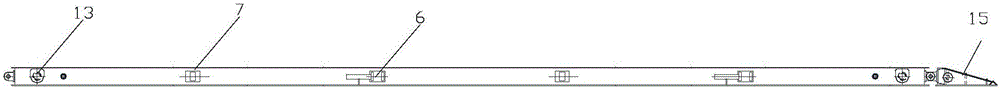

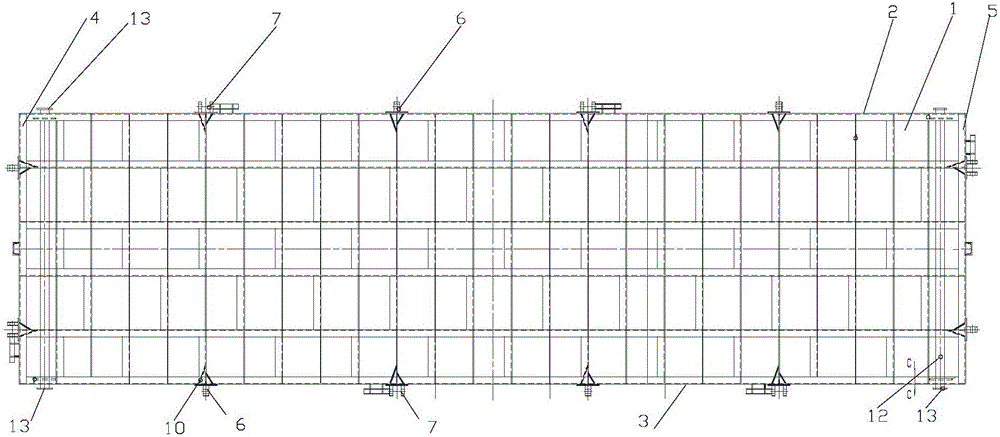

[0015] attached figure 1 combine figure 2 As shown, the drilling auxiliary platform of the tidal flat well site includes a steel plate roadbed box, and the steel plate roadbed box is connected to the approach road 15; as image 3 As shown, the steel plate embankment box includes an airtight single-piece body 1, and the single-piece body 1 is formed by intersecting a plurality of cross braces and longitudinal beams to form a through-beam horizontal grid and a vertical grid. The upper and lower ends of the single-piece body 1 The upper cross brace 2 and the lower cross brace 3 are respectively connected, and the left and right sides are respectively the left side beam 4 and the right side side beam 5; the periphery of the single-piece body 1 is provided with 6 sets of single ear seats 6 and double ear seats 7 , the one-ear seat 6 and the two-ear seat 7 are equipped with co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com