A steel plate combined steel pipe concrete drainable manhole cover

A technology of combining steel pipes and drainage manhole covers, applied in drainage structures, waterway systems, water supply devices, etc., can solve the problems of lack of functionality, high manufacturing cost of manhole covers, unreasonable structure of manhole covers, etc., and achieve the effect of strengthening strength and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

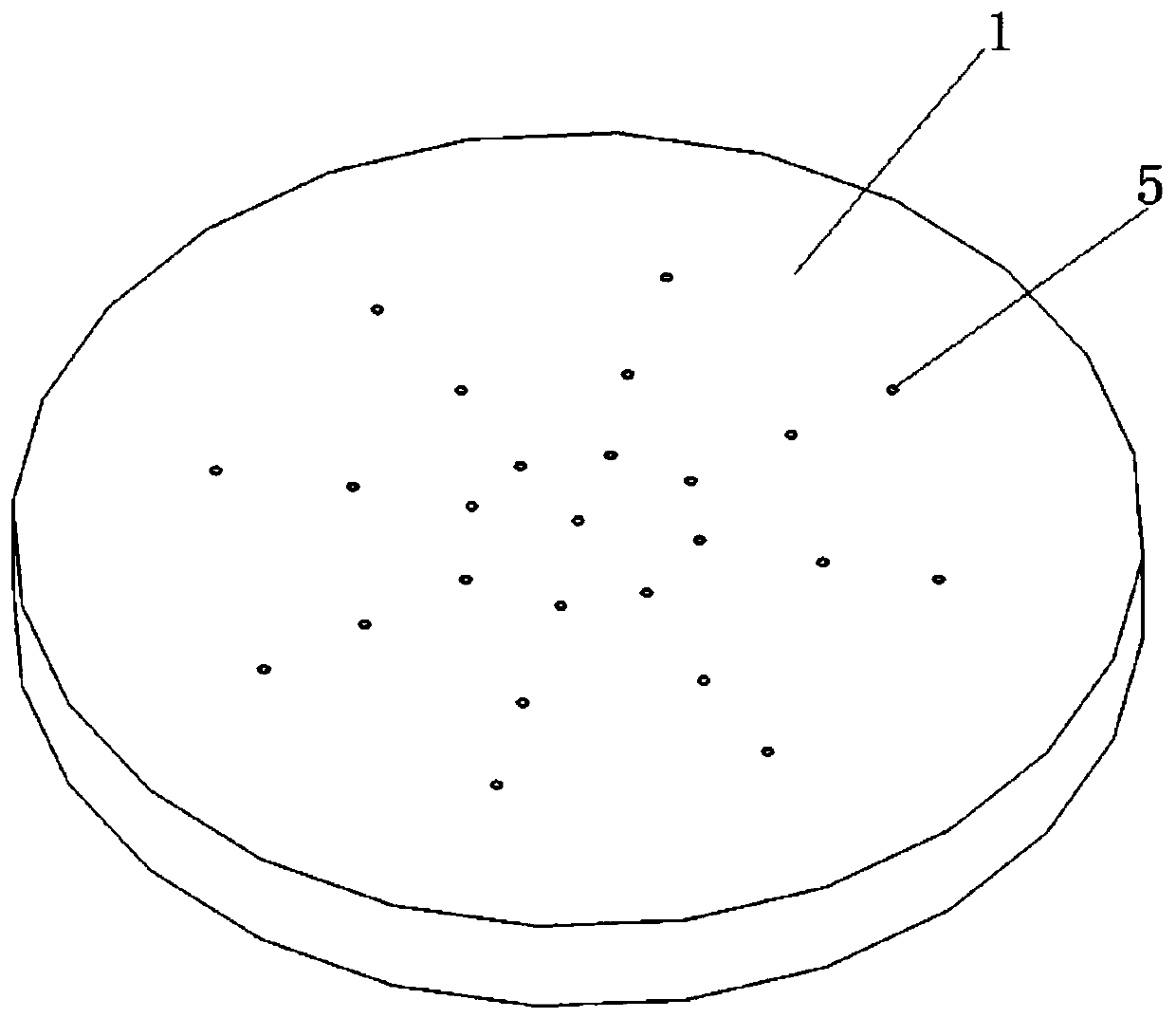

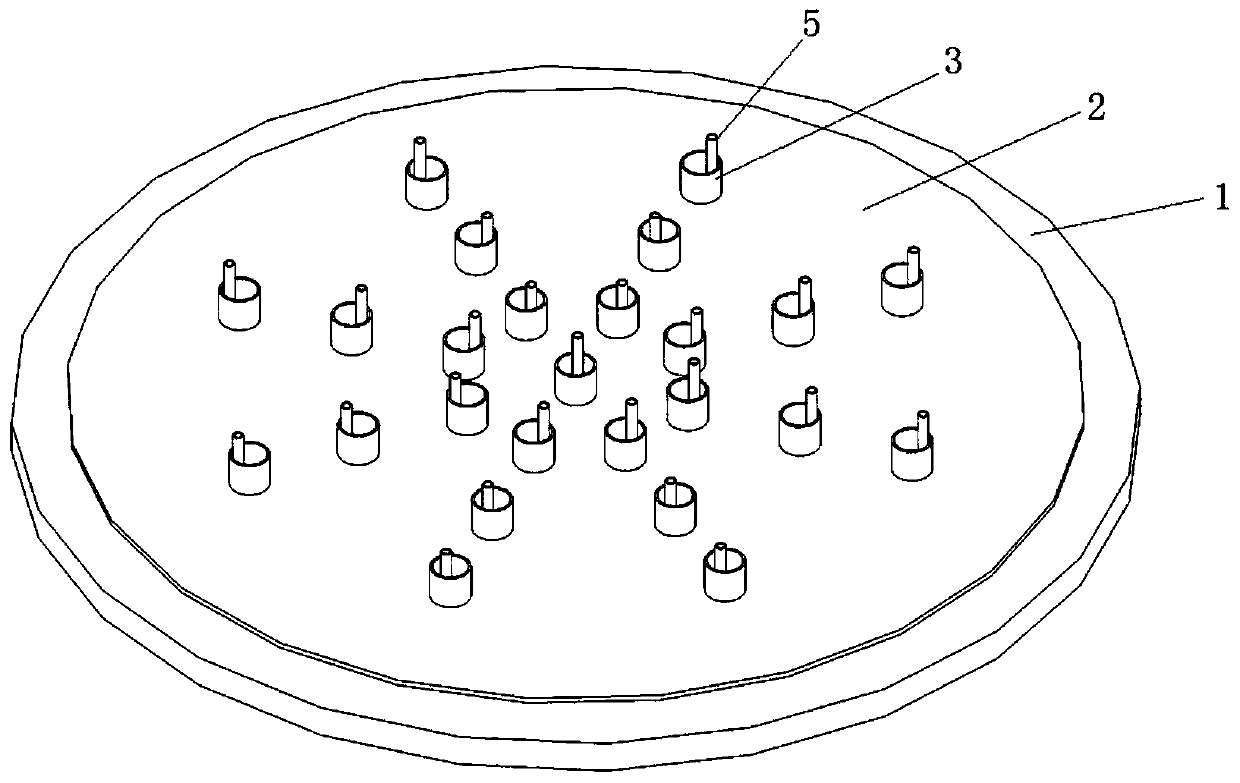

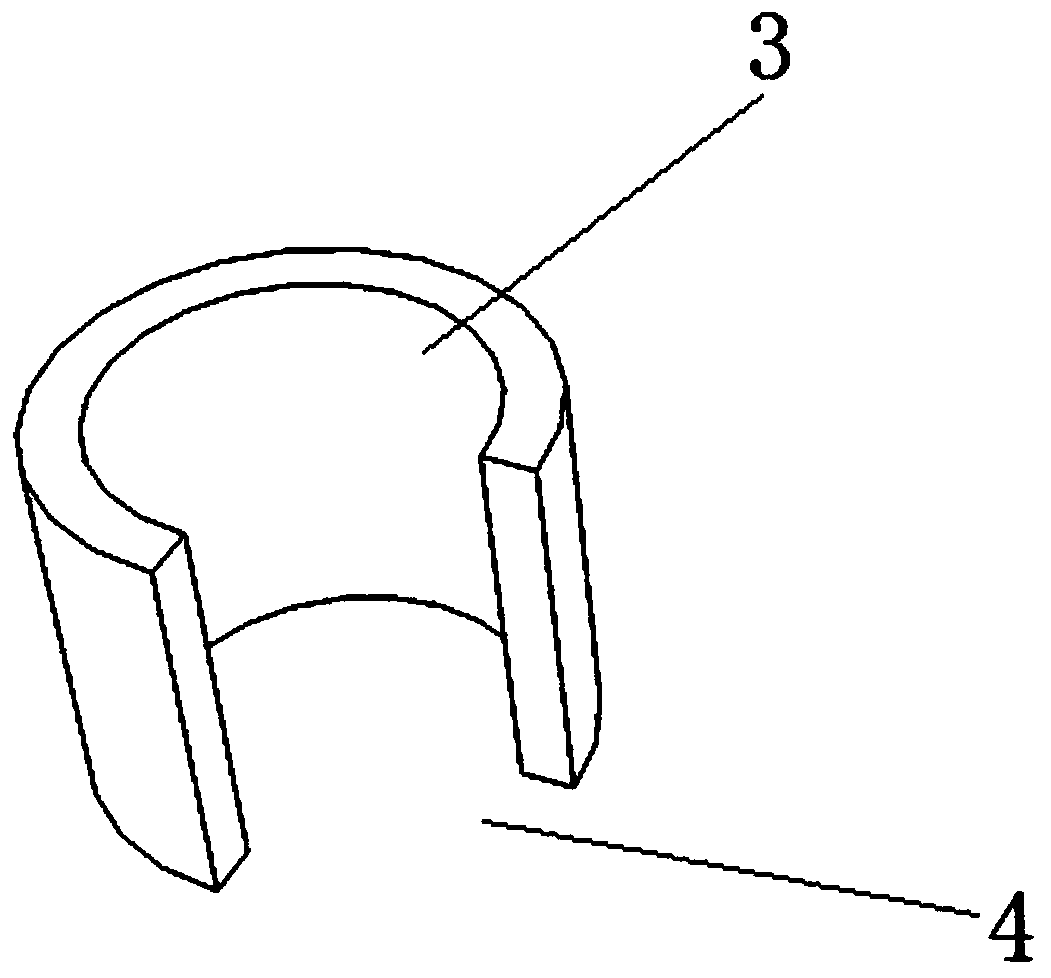

[0023] like Figure 1~4 As shown, a steel plate composite steel pipe concrete drainable manhole cover includes a disc-shaped concrete cover body 1, a steel plate 2 is embedded on the bisector surface of the concrete cover body 1 in the thickness direction, and the upper and lower surfaces of the steel plate 2 are welded to the steel plate 2. A plurality of cylindrical steel pipes 3 symmetrically distributed, the inner walls of the steel pipes 3 are connected with drainage pipes 5, the drainage pipes 5 run through the entire thickness of the concrete cover body 1 (including the steel plate 2), and the two ends thereof are flush with the upper and lower surfaces of the concrete cover body 1 together. The central axis of the steel pipe 3 is perpendicular to the surface of the steel plate 2, and the circumferential surface of the steel pipe 3 is an unclosed surface, such as image 3 As shown, the area of the notch 4 accounts for 1 / 4 of the total circumferential area, the length...

Embodiment 2

[0025] like Figure 5-6 As shown, the difference between this embodiment and embodiment 1 is that the steel plate 2 adopts Image 6 In the non-flat steel plate with a thick middle and a thin edge, the steel plate 2 has five through holes, and the edges are connected to the concrete on the upper and lower ends of the steel plate 2 to form a whole. The number (density) of the steel pipes 3 in the edge area of the steel plate 2 is greater than that in the central area, and the height of the steel pipes 3 in the edge area is greater than that in the central area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com