A variable frequency variable capacity heat pump hot air drying system and its control method

A technology of hot air drying and variable capacity, which is applied to heat pumps, drying machines, dryers, etc., to achieve the effects of reducing energy consumption, improving energy efficiency, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

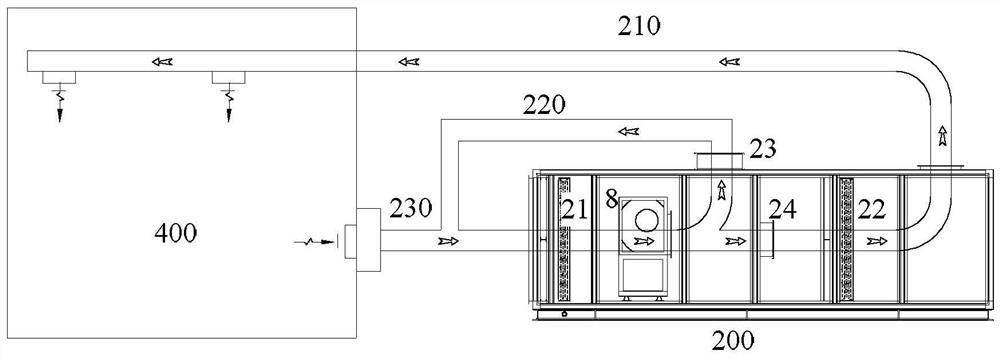

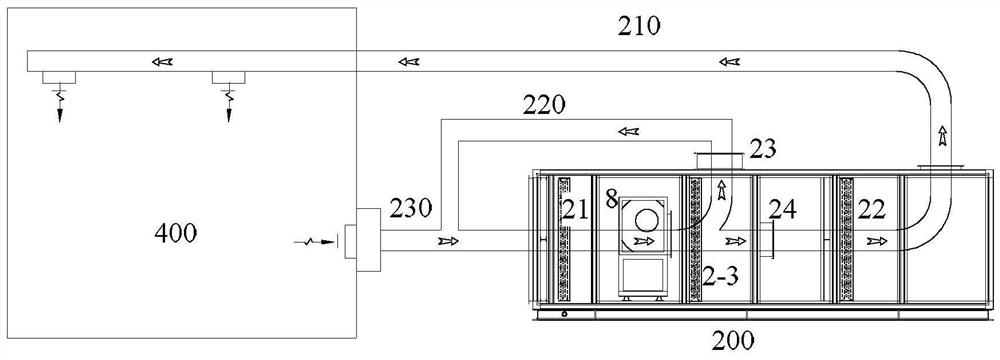

Embodiment 1

[0075] An example of the multi-stage temperature control curve and the temperature control parameter configuration interface is: Figure 8 As shown, the multi-stage temperature control curve in this embodiment is a 10-stage heating curve, and the control device 500 controls the dual-circulation hot air drying system to realize intelligent automatic operation by configuring the set temperature and temperature stabilization time of each time period, No manual manipulation required.

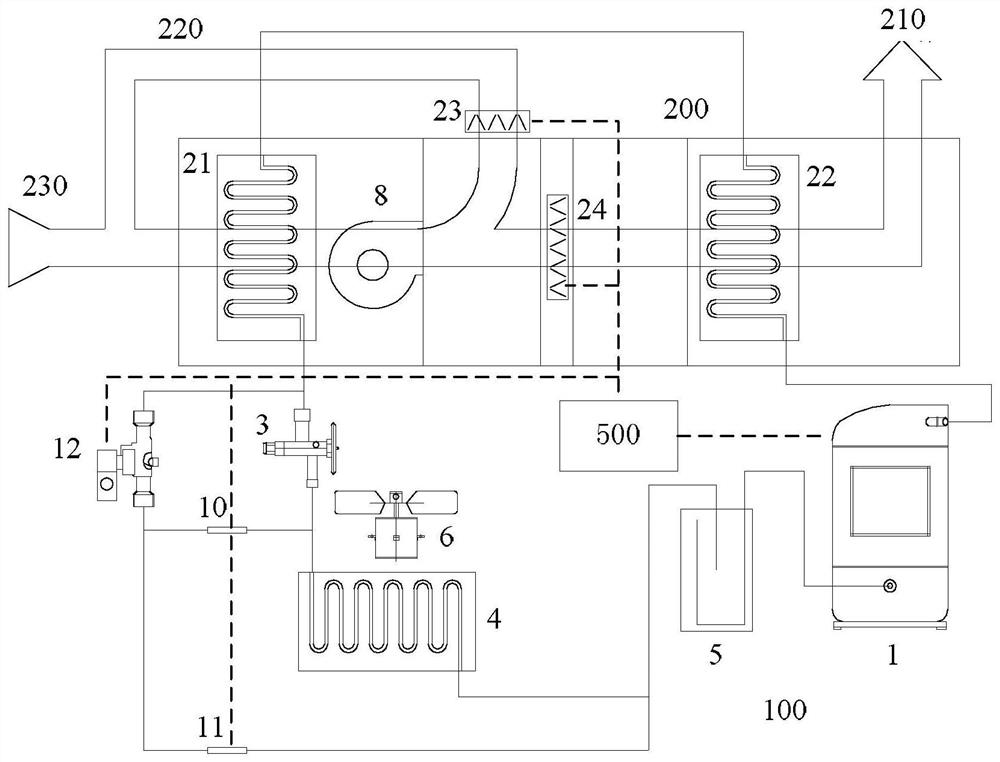

[0076] according to Image 6 In the embodiment of the control method of the heat pump type dual-cycle hot air drying system of the present invention shown, the step S400 includes the following control operations:

[0077] S420: If the set temperature is less than 45°C, close the unloading solenoid valve 12 and enter the single-cycle conventional heating mode; in this mode, the opening degree of the internal circulation air valve 23 is 0%, and the opening degree of the air supply regulating valve 24...

Embodiment 2

[0082] The size of a tobacco drying room is: 8 × 2.8 × 2.2 m, and the amount of tobacco leaves dried at one time is 350 rods, each of which is 30 kg of tobacco leaves, totaling 10,500 kg. The variable-frequency variable-capacity heat pump hot air drying system consists of a 6-hp fixed-frequency compressor 1-1 and a 6-hp variable-frequency compressor 1-2 in parallel, with a maximum heating capacity of 50kW. The frequency conversion and variable capacity connection structure of the unit is as follows Figure 4 shown. For the temperature control curve of the flue-cured tobacco process, see Figure 9 As shown in the multi-stage drying process diagram, the heat consumption in each period is as follows: Figure 10 shown. The control device 500 selects an appropriate operation mode through comparative analysis to achieve maximum operation efficiency.

[0083] according to Figure 7 In the embodiment of the control method of the variable frequency variable capacity heat pump hot ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com