Quenching heat exchanger

A technology for quenching heat exchangers and heat exchangers, which is applied in the types of heat exchangers, direct contact heat exchangers, water shower coolers, etc. requirements and other issues, to achieve the effect of accelerating the flow rate of flue gas, the best effect, and strengthening the disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

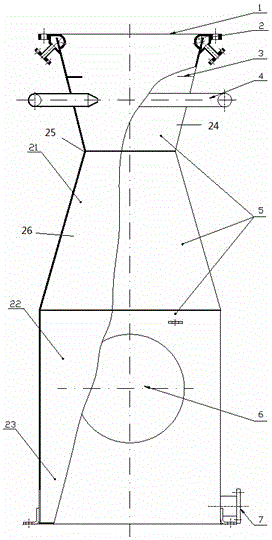

[0044] figure 1 An overall cutaway view of the quench heat exchanger is shown. like figure 1 As shown, the quench heat exchanger includes a shell 5, and the shell 5 includes a tapering section 24 and a diverging section 26, and the converging section 24 and the diverging section 26 are connected by a throat section 25; The tapered section 24 enters, first passes through the tapered section 24 and then passes through the tapered section 26 , and a chilling ring 2 is set at the position of the flue gas inlet 1 of the tapered section 24 .

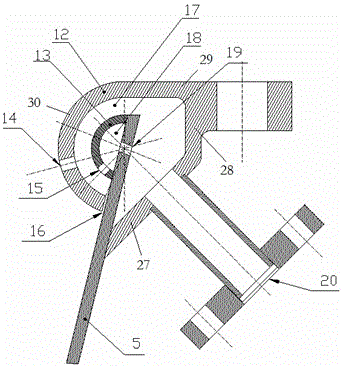

[0045] like figure 2 As shown, the quenching ring 2 is a hollow ring structure. The quenching ring 2 includes an inner ring chamber 18 and an outer ring chamber 17, and the housing 5 is inserted into the quenching ring 2, as figure 2 As shown, the quench ring 2 includes an outer shell 12 and an inner partition 13 . The inner partition 13 and the casing 5 form an inner chamber 18 , and the cavity formed by the inner partition 13 , the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com