Byproduct cooling device in starch production

A technology for cooling devices and by-products, applied in household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of high production cost, low production efficiency, low efficiency, etc., and achieve high equipment stability and heat exchange efficiency. , Process control and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

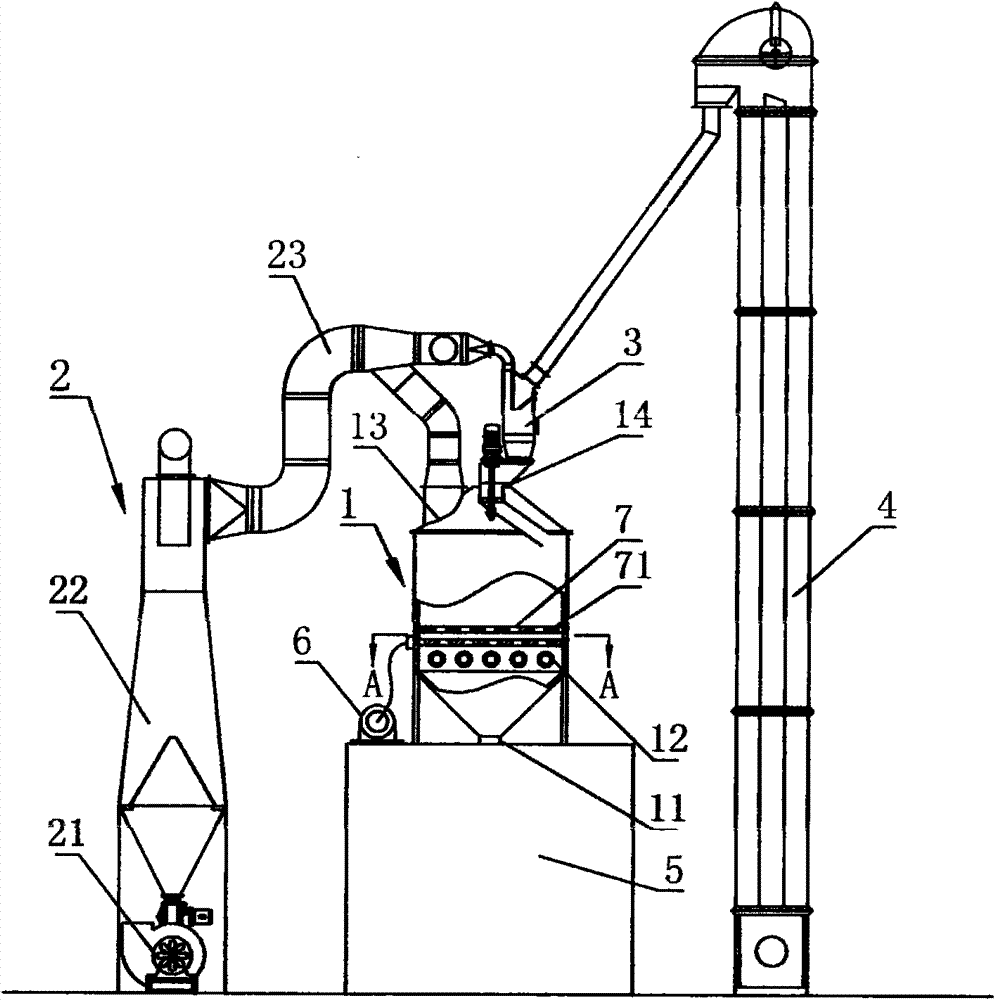

[0020] Such as figure 1 and figure 2 Commonly shown, the by-product cooling device in starch production includes a cooler 1 with a material outlet 11 at the bottom, a cold air inlet 12 at the bottom, a hot air outlet 13 and a material inlet 14 at the top, and the hot air outlet 13 is connected to a dust removal Device 2, the material inlet 14 is provided with a secondary cooler 3, the hoist 4 is connected to the material inlet 14 of the cooler 1 through the secondary cooler 3, and the top of the secondary cooler 3 is connected to the dust removal device 2. The cooler 1 is provided with a discharge grid 7 driven by a vibrating motor 6 , and the cold air inlet 12 is located at the lower part of the discharge grid 7 . The dust removal device 2 includes a dust remover 22 driven by a dust removal fan 21 , and the dust remover 22 communicates with the hot air outlet 13 and the top of the secondary cooler 3 through a dust removal pipe 23 .

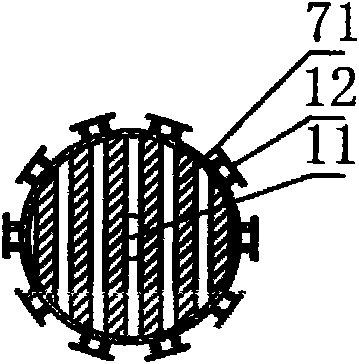

[0021] The discharge grid 7 comprises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com