Water-cooled anode of plasma generator

A technology for plasma generators and water-cooled anodes, applied in the direction of plasma, electrical components, etc., can solve the problems of high temperature, short life, and inability to meet high-power plasma generators, and achieve good cooling effect, water distribution and uniform heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

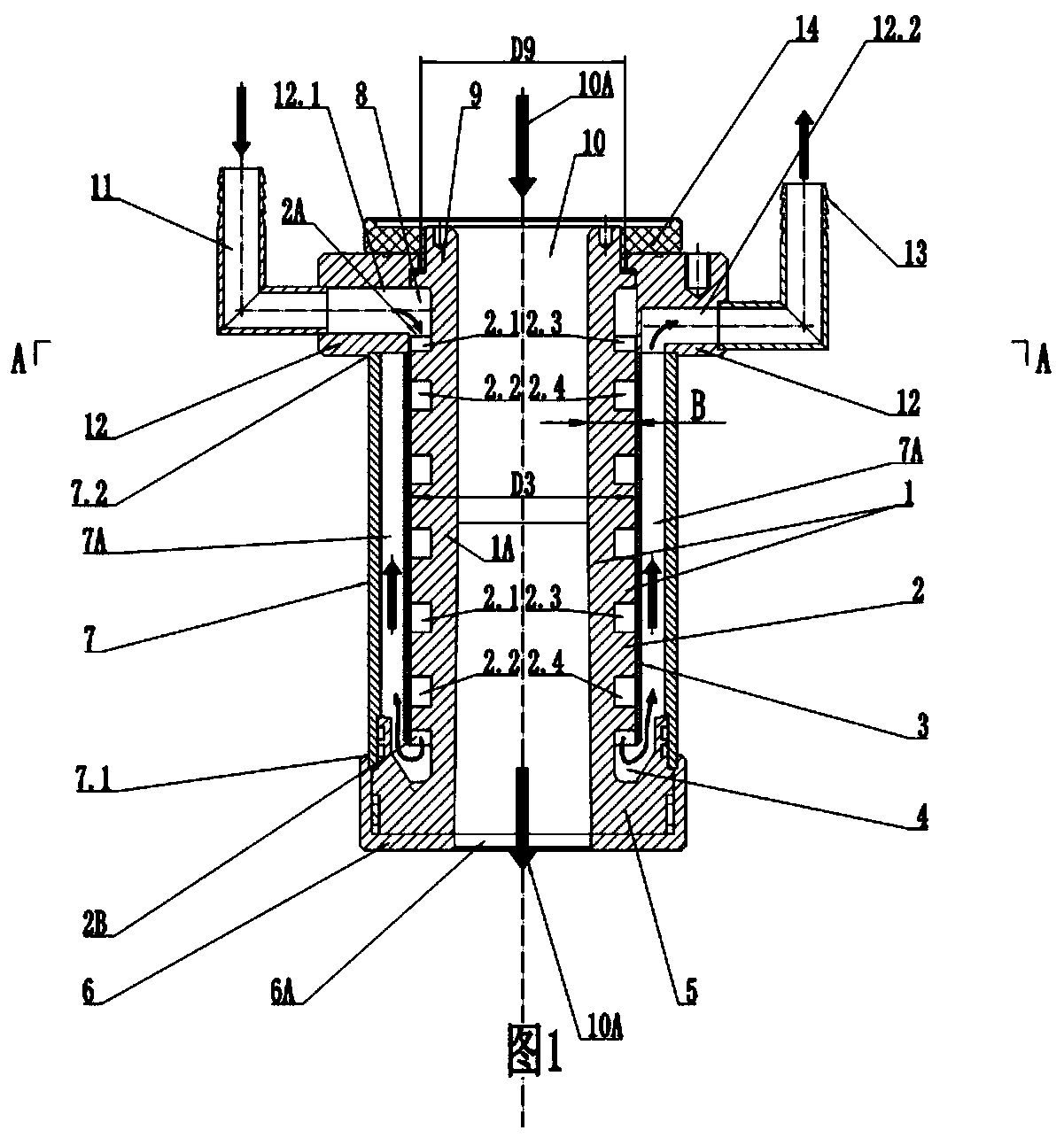

[0018] EXAMPLES Large anodes for non-transferred arc plasma generators.

[0019] The water-cooled anode of the plasma generator is composed as follows:

[0020] 1) Overall structure and layout:

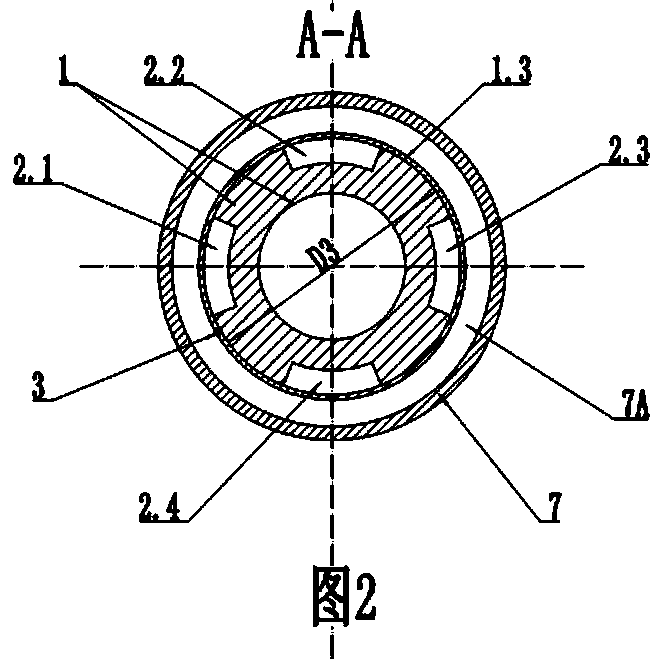

[0021] See figure 1 , on the cylindrical anode with a central hole 10, within the range of radial wall thickness B, a spiral inner anode 1 is arranged, and the outer surface of the spiral inner anode is provided with N upper water inlets 2A uniformly distributed in the circumferential direction formed by axial threads. And the spiral channel 2 of the water outlet 2B below. See figure 2 , the spiral water channel 2 is axially wound by N threads, and N is taken as 4 in this embodiment; a cylindrical outer anode 3 is set on the outer surface of the spiral inner anode 1, and there are groove teeth between the spiral inner anode and the outer anode. The spiral arc surface 1.3 (see figure 2 ), the matching gap between the spiral arc surface 1.3 and the inner hole of the outer anode 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com