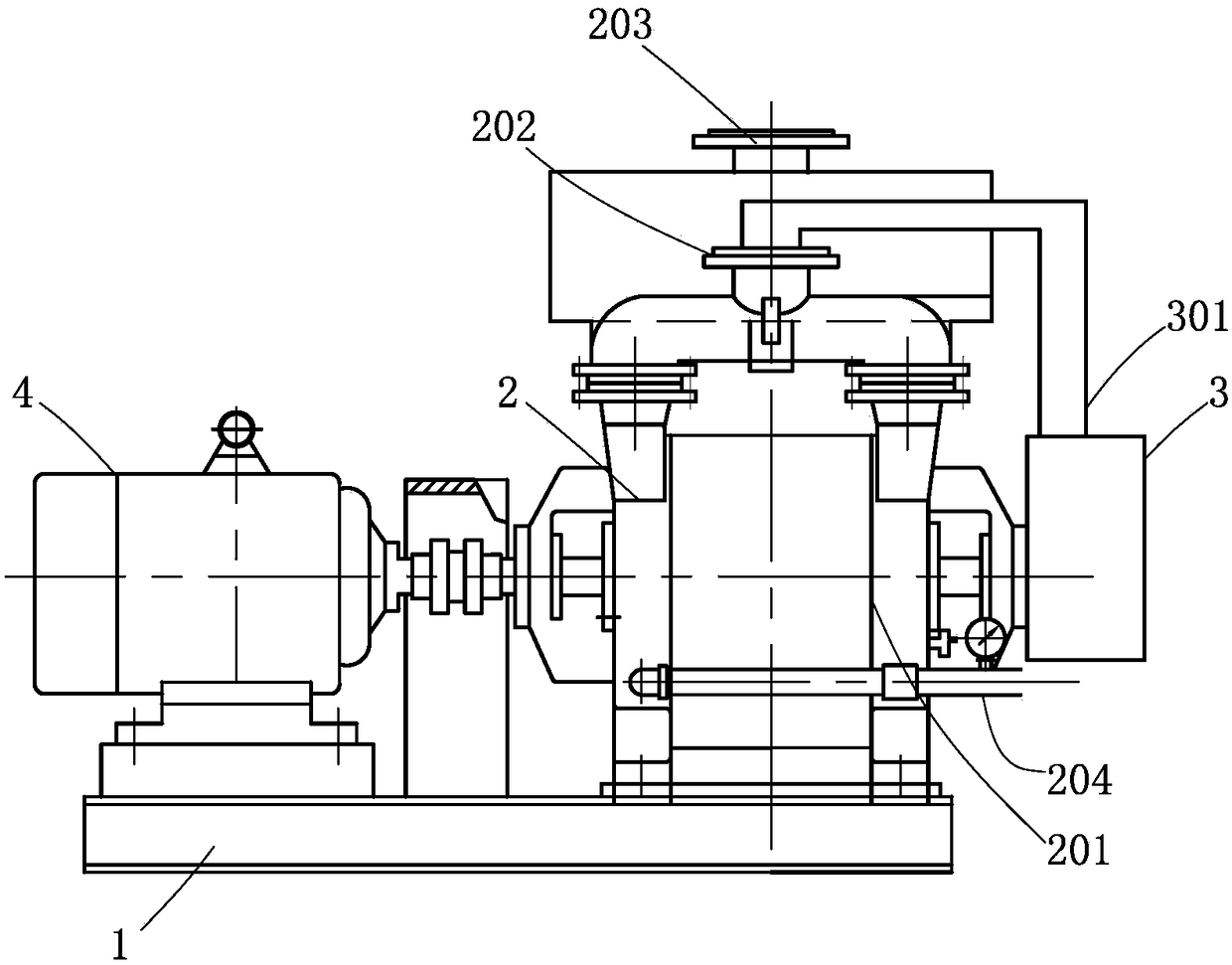

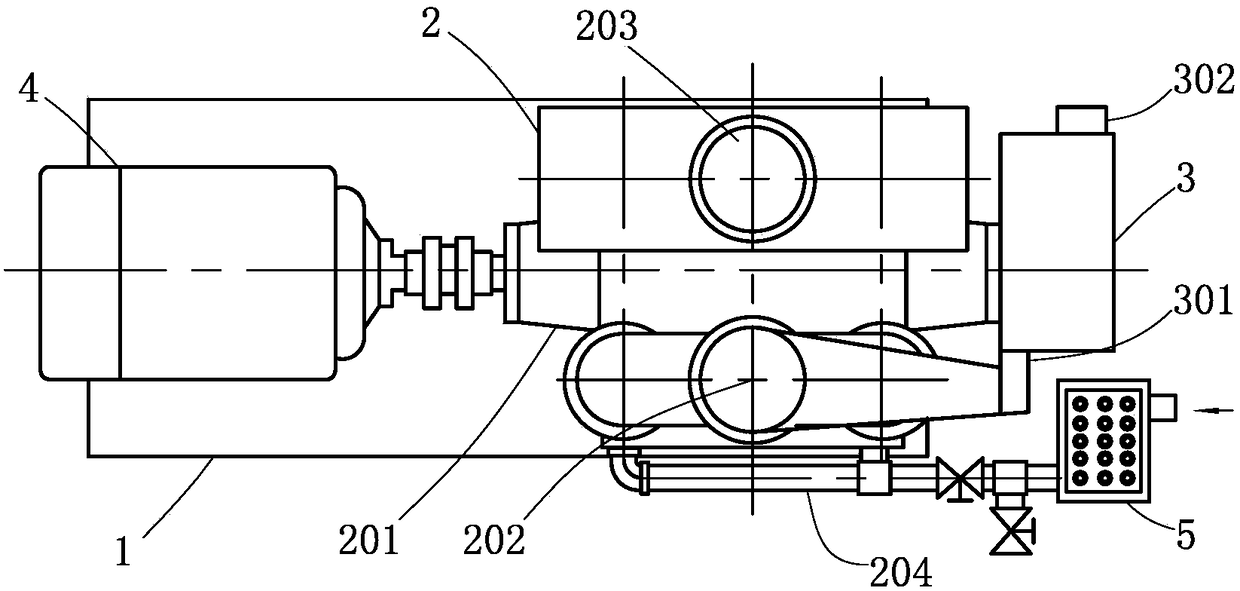

A combination vacuum pump

A combined pump and water ring vacuum pump technology, applied to pumps, pump components, rotary piston pumps, etc., can solve the problems of complex structure, low service life, high power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0082] Preparation Example: Preparation of Modified Calcium Sulfate Whiskers

[0083] A1: Cut the calcium sulfate whiskers to a length of 0.3mm, add them to a sufficient amount of absolute ethanol, ultrasonically clean them for 25 minutes, filter, wash the calcium sulfate whiskers with deionized water for 2-3 times, and remove them. , fully dried to obtain clean calcium sulfate whiskers;

[0084] A2: Add clean calcium sulfate whiskers to dehydrated alcohol of 9 times its mass, then slowly add the dehydrated ethanol solution of isopropyl orthosilicate (the clean calcium sulfate whiskers and isopropyl orthosilicate The mass ratio of the isopropyl orthosilicate is 1:0.5, and the mass percentage concentration of the isopropyl orthosilicate is 25%), stirred and reacted for 50 minutes, filtered, and the obtained whiskers were fully washed 3-4 times with deionized water, dried, and The obtained dried whiskers were calcined at 320° C. for 35 minutes, and cooled naturally to room temp...

Embodiment 1

[0086] S1: According to the weight ratio of 2:1:1, weigh phenol A type epoxy resin, methacrylic acid-butadiene-styrene terpolymer (MBS resin) and polyvinyl chloride, and use a high-speed mixer to carry out Fully and evenly mixed to obtain 80 parts by weight of resin masterbatch;

[0087]S2: Add 1 part by weight of the modified calcium sulfate whisker obtained in the preparation example, 1 part by weight of the stabilizer isooctyl dimethyl tin dimercaptoacetate, and 3 parts by weight of the toughening agent methyl methacrylate into the above resin masterbatch -butadiene-styrene terpolymer (MBS), 0.4 parts by weight of nano carbon black, 3 parts by weight of dilaurate thiodipropionate, 1 part by weight of two-component antioxidant (for mass ratio 1: 1 Tris(2,4-di-tert-butylphenyl)phosphite and 1,3,5-trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl base) benzene mixture), 0.8 parts by weight of adhesion promoter formula (I) compound, 6 parts by weight of auxiliary agent (b...

Embodiment 2

[0090] S1: According to the weight ratio of 2:1:1, weigh phenol A type epoxy resin, methacrylic acid-butadiene-styrene terpolymer (MBS resin) and polyvinyl chloride, and use a high-speed mixer to carry out Fully and evenly mixed to obtain 80 parts by weight of resin masterbatch;

[0091] S2: Add 0.5 parts by weight of the modified calcium sulfate whisker obtained in the preparation example, 2 parts by weight of the stabilizer isooctyl dimethyl tin dimercaptoacetate, and 2 parts by weight of the toughening agent methyl methacrylate into the above resin masterbatch -butadiene-styrene terpolymer (MBS), 0.8 parts by weight of nano carbon black, 2 parts by weight of dilaurate thiodipropionate, 1.6 parts by weight of two-component antioxidant (for mass ratio 1: 2 Tris(2,4-di-tert-butylphenyl)phosphite and 1,3,5-trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl base) benzene mixture), 0.5 parts by weight of adhesion promoter formula (I) compound, 8 parts by weight of auxiliary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com