Straw pulling force tester

A pull-out force and tester technology, applied in the field of force measurement, can solve problems such as inability to pull up vertically, inaccurate pull-out force measurement, etc., to achieve improved grip and adaptability, accurate pull-out force, and simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

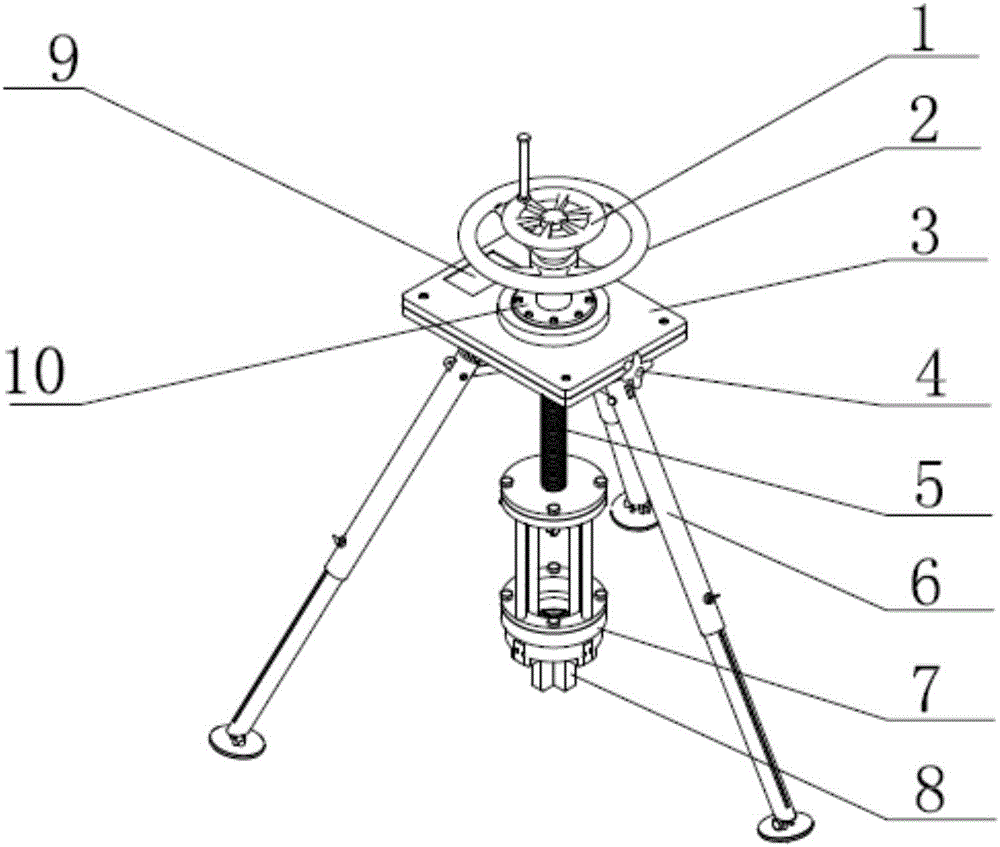

[0033] The straw pulling force tester includes a vertical holding mechanism 10 , a clamping mechanism, a lifting mechanism and a bracket 6 .

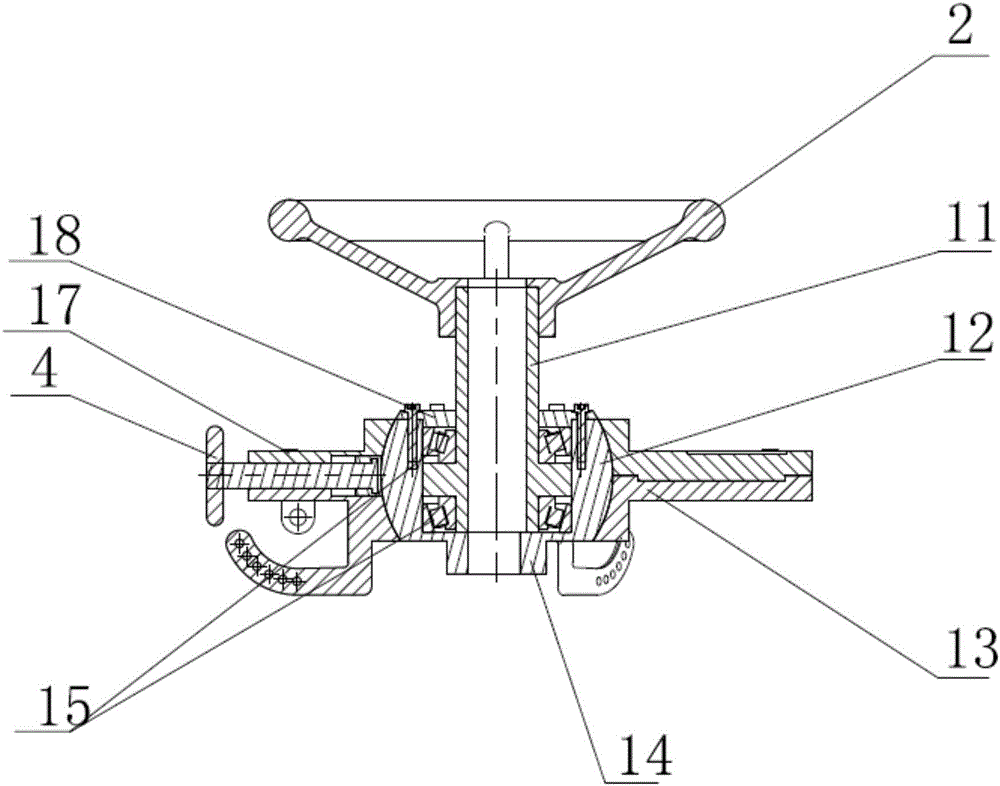

[0034] Such as figure 2 As shown, the vertical holding mechanism 10 includes a workbench 3, a spherical sleeve 12, a spherical sleeve cover 18 and a pressing device 4, wherein the workbench 3 includes an upper part 17 of the workbench and a lower part 13 of the workbench, and the upper part of the workbench 17 is fixed above the lower part 13 of the workbench, and a pressing device 4 is arranged between the upper part 17 of the workbench and the lower part 13 of the workbench. The ball sleeve 12 is arranged at the center of the workbench 3 and is located inside the workbench 3 . The top of the spherical sleeve 12 is fixed with a spherical sleeve cover 18 , and the bottom of the spherical sleeve 12 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com