High Resolution Industrial Camera Lens

A camera lens, high-resolution technology, applied in the field of high-resolution industrial camera lens, to achieve the effect of compact structure, high resolution and accurate precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

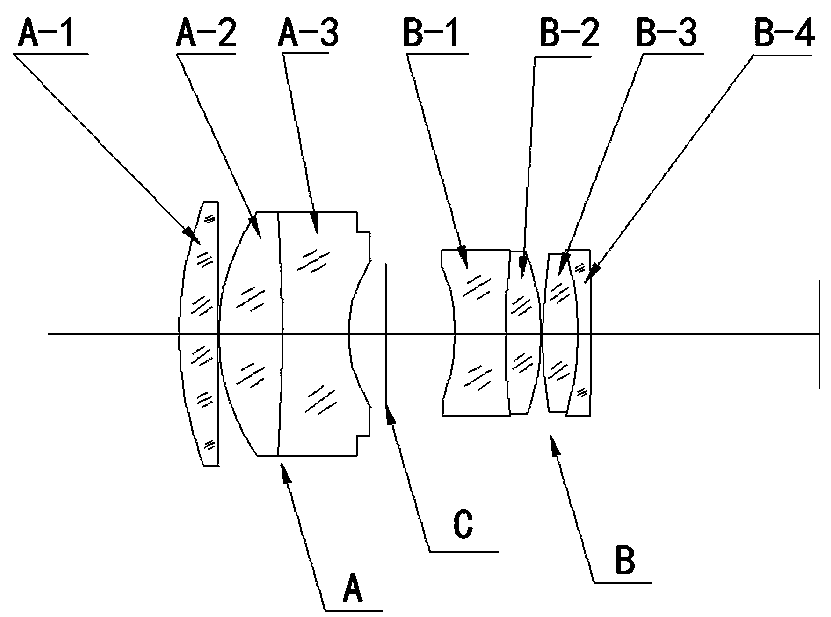

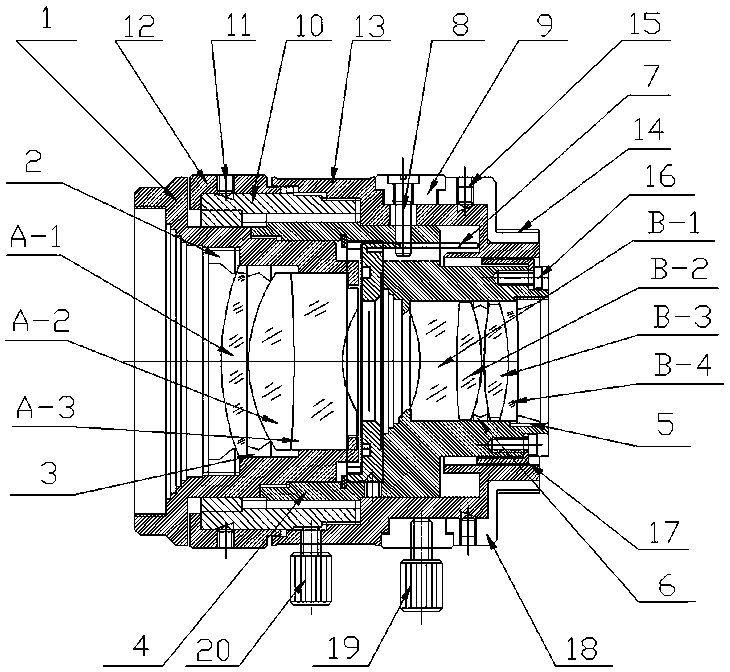

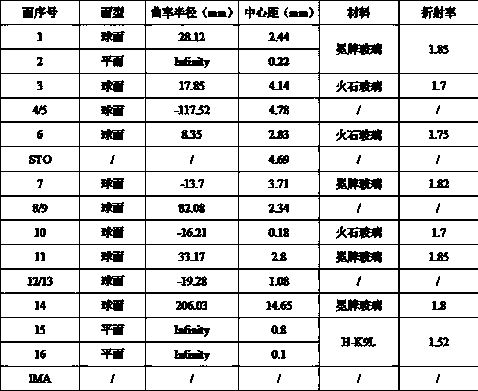

[0028] Such as Figure 1~2 As shown, a high-resolution industrial camera lens includes a front group A with a negative focal power, a variable diaphragm C, and a rear group B with a positive refractive power arranged in sequence along the incident direction of light from left to right. The front group A is composed of a positive crescent lens A-1, a biconvex lens A-2 and a biconcave lens A-3, and the biconvex lens A-2 and the biconcave lens A-3 are closely connected to form the first The cemented group, the rear group B is composed of a biconcave lens B-1, a biconvex lens B-2, a biconvex lens B-3 and a negative crescent lens B-4, and the biconcave lens B-1 and The double-convex lens B-2 is tightly bonded to form the second cemented group, and the double-convex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com