Numerical method for fast determining process parameters of hot punching production line

A technology of process parameters and numerical method, which is applied in the numerical field of quickly determining process parameters of hot stamping production line, can solve the problems of poor product quality consistency, unstable product quality, low debugging efficiency, etc., to speed up the development process and shorten the mode process production. and on-site debugging process to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

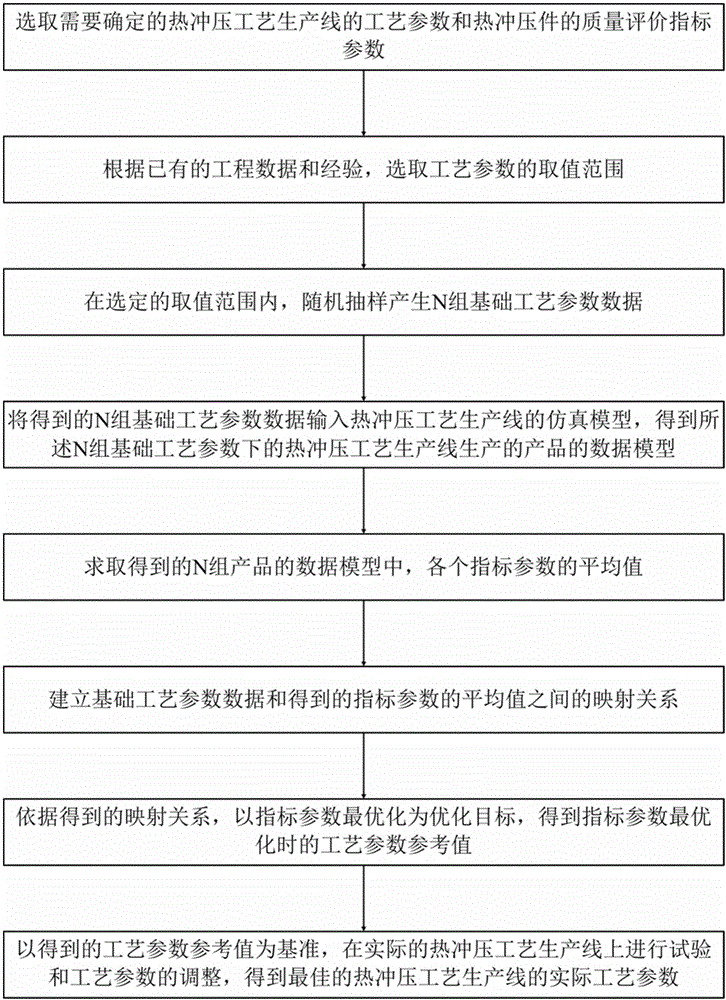

[0034] Such as figure 1 Shown is the method flow chart of the present invention: the numerical method for quickly determining the process parameters of the hot stamping production line provided by the present invention includes the following steps:

[0035] S1. Select the process parameters of the hot stamping production line that need to be determined (such as holding temperature, transfer time, blank holder force, holding pressure and holding quenching time) and the quality evaluation index parameters of hot stamping parts (such as Vickers hardness, resistance tensile strength and martensite content);

[0036] S2. According to the existing engineering data and experience, select the value range of the technological parameter of step S1;

[0037] S3. Within the value range selected in step S2, adopt Latin hypercube sampling to generate N groups of basic process parameter data;

[0038] S4. Input the N groups of basic process parameter data obtained in step S3 into the simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com