An improved rcm analysis method and a dynamic equipment integrity evaluation system based thereon

An analysis method and improved technology, applied in the field of improved RCM analysis method and dynamic equipment integrity evaluation system based on it, can solve the problems of inaccurate RCM decision, inability to reuse, reduce analysis efficiency and accuracy, etc., to improve Practical and scientific, ensure accuracy and scientific, and reduce the effect of the overall workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

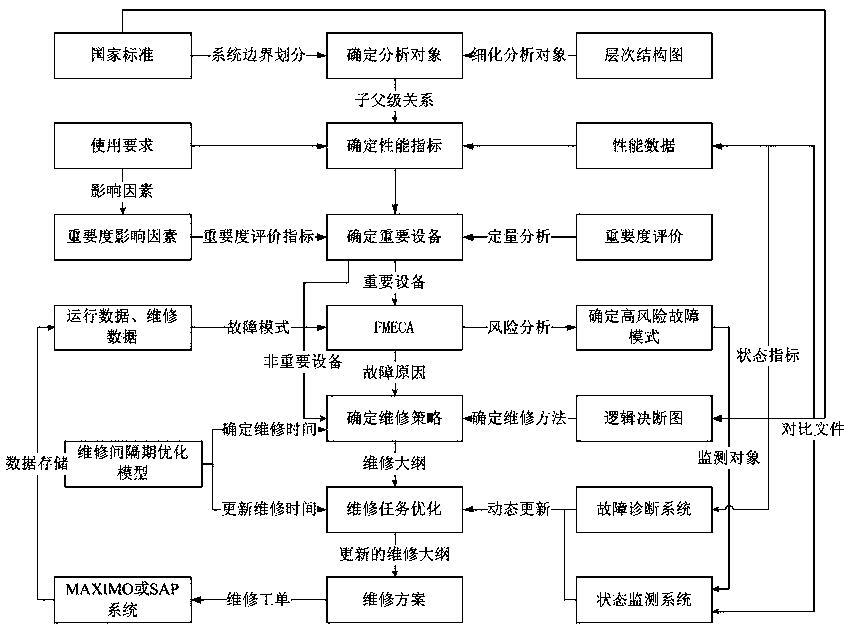

[0093] Such as figure 1 Shown, a kind of improved RCM analysis method comprises the following steps:

[0094] S1. Determine the analysis object: divide the boundary of the offshore platform mobile equipment system according to the national standard, and construct a hierarchical structure tree of all equipment included in the offshore platform mobile equipment.

[0095] After selecting the analysis object, divide the system boundary of offshore platform dynamic equipment according to the determination method of equipment boundary and analysis system in national standards; A structure tree for a system or device. During the establishment of the structure tree, it must be ensured that important products will not be missed, and failures will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com