Special lifting mechanism for pseudo-ginseng seeding machine

A technology of jacking mechanism and seeder, which is applied in the direction of seeder parts, sowing, application, etc., can solve the problems of complex structure of jacking mechanism, high cost of design and processing, and achieve overall improvement of flexibility, good operation quality, and improvement of sowing The effect of working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

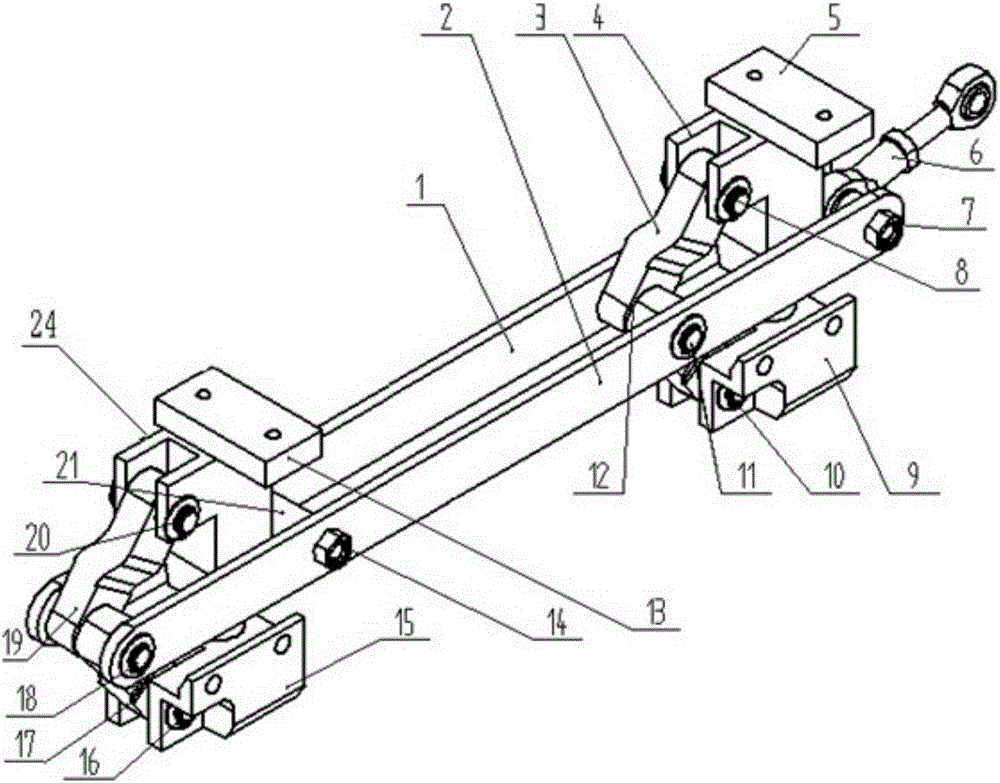

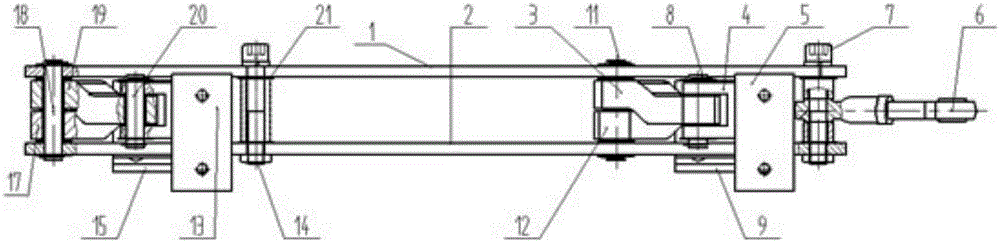

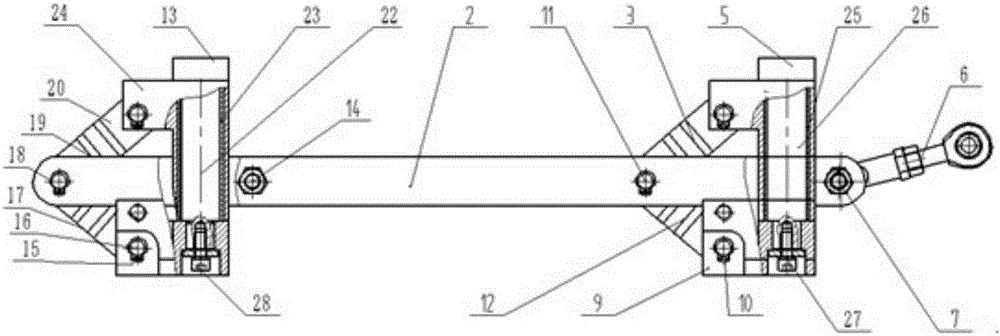

[0021] Embodiment 1: as Figure 1-5 As shown, a special jacking mechanism for panax notoginseng seeder, including connecting rod I1, connecting rod II2, jacking arm I3, jacking upper support I4, fixed mounting plate I5, mechanism pull rod 6, pull rod fixing pin 7, Pin Ⅰ8, lower support Ⅰ9, pin Ⅱ10, pin Ⅲ11, jacking arm Ⅱ12, fixed mounting plate Ⅱ13, pin Ⅳ14, lower support Ⅱ15, pin Ⅴ16, jacking arm Ⅲ17, pin Ⅵ18 , Jacking arm Ⅳ19, pin shaft Ⅶ20, fixed sleeve 21, jacking guide shaft Ⅱ22, solid inlaid bearing Ⅱ23, jacking upper support Ⅱ24, solid inlaid bearing Ⅰ25, jacking guide shaft Ⅰ26, jacking guide shaft fixing bolt Ⅰ27, jacking guide shaft fixing bolt Ⅱ28;

[0022] The jacking arm I3 and the jacking arm II12 are connected together through the pin shaft III11, the jacking arm I3 is installed together with the pin hole on the jacking upper support I4 through the pin shaft I8, and the mounting plate is fixed Ⅰ5 is fixed on the jacking upper support Ⅰ4 through bolt connection...

Embodiment 2

[0025] Embodiment 2: as Figure 1-5 As shown, a special jacking mechanism for Panax notoginseng seeder, including connecting rod I1, connecting rod II2, jacking arm I3, jacking upper support I4, fixed mounting plate I5, mechanism pull rod 6, pull rod fixing pin 7, Pin Ⅰ8, lower support Ⅰ9, pin Ⅱ10, pin Ⅲ11, jacking arm Ⅱ12, fixed mounting plate Ⅱ13, pin Ⅳ14, lower support Ⅱ15, pin Ⅴ16, jacking arm Ⅲ17, pin Ⅵ18 , Jacking arm Ⅳ19, pin shaft Ⅶ20, fixed sleeve 21, jacking guide shaft Ⅱ22, solid inlaid bearing Ⅱ23, jacking upper support Ⅱ24, solid inlaid bearing Ⅰ25, jacking guide shaft Ⅰ26, jacking guide shaft fixing bolt Ⅰ27, jacking guide shaft fixing bolt Ⅱ28;

[0026]The jacking arm I3 and the jacking arm II12 are connected together through the pin shaft III11, the jacking arm I3 is installed together with the pin hole on the jacking upper support I4 through the pin shaft I8, and the mounting plate is fixed Ⅰ5 is fixed on the jacking upper support Ⅰ4 through bolt connection,...

Embodiment 3

[0028] Embodiment 3: as Figure 1-5 As shown, a special jacking mechanism for panax notoginseng seeder, including connecting rod I1, connecting rod II2, jacking arm I3, jacking upper support I4, fixed mounting plate I5, mechanism pull rod 6, pull rod fixing pin 7, Pin Ⅰ8, lower support Ⅰ9, pin Ⅱ10, pin Ⅲ11, jacking arm Ⅱ12, fixed mounting plate Ⅱ13, pin Ⅳ14, lower support Ⅱ15, pin Ⅴ16, jacking arm Ⅲ17, pin Ⅵ18 , Jacking arm Ⅳ19, pin shaft Ⅶ20, fixed sleeve 21, jacking guide shaft Ⅱ22, solid inlaid bearing Ⅱ23, jacking upper support Ⅱ24, solid inlaid bearing Ⅰ25, jacking guide shaft Ⅰ26, jacking guide shaft fixing bolt Ⅰ27, jacking guide shaft fixing bolt Ⅱ28;

[0029] The jacking arm I3 and the jacking arm II12 are connected together through the pin shaft III11, the jacking arm I3 is installed together with the pin hole on the jacking upper support I4 through the pin shaft I8, and the mounting plate is fixed Ⅰ5 is fixed on the jacking upper support Ⅰ4 through bolt connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com