A Mechanized Harvesting Process and Equipment for Mudflat Clams

A clam and equipment technology, applied in the field of tidal flat clam harvesting, can solve problems such as irrational migration of sediment layers, uneven distribution of sediment layers, and changes in tidal flat strata structure, so as to expand the range of ultrasonic stimulation and increase shelling operations Area, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the drawings and specific embodiments.

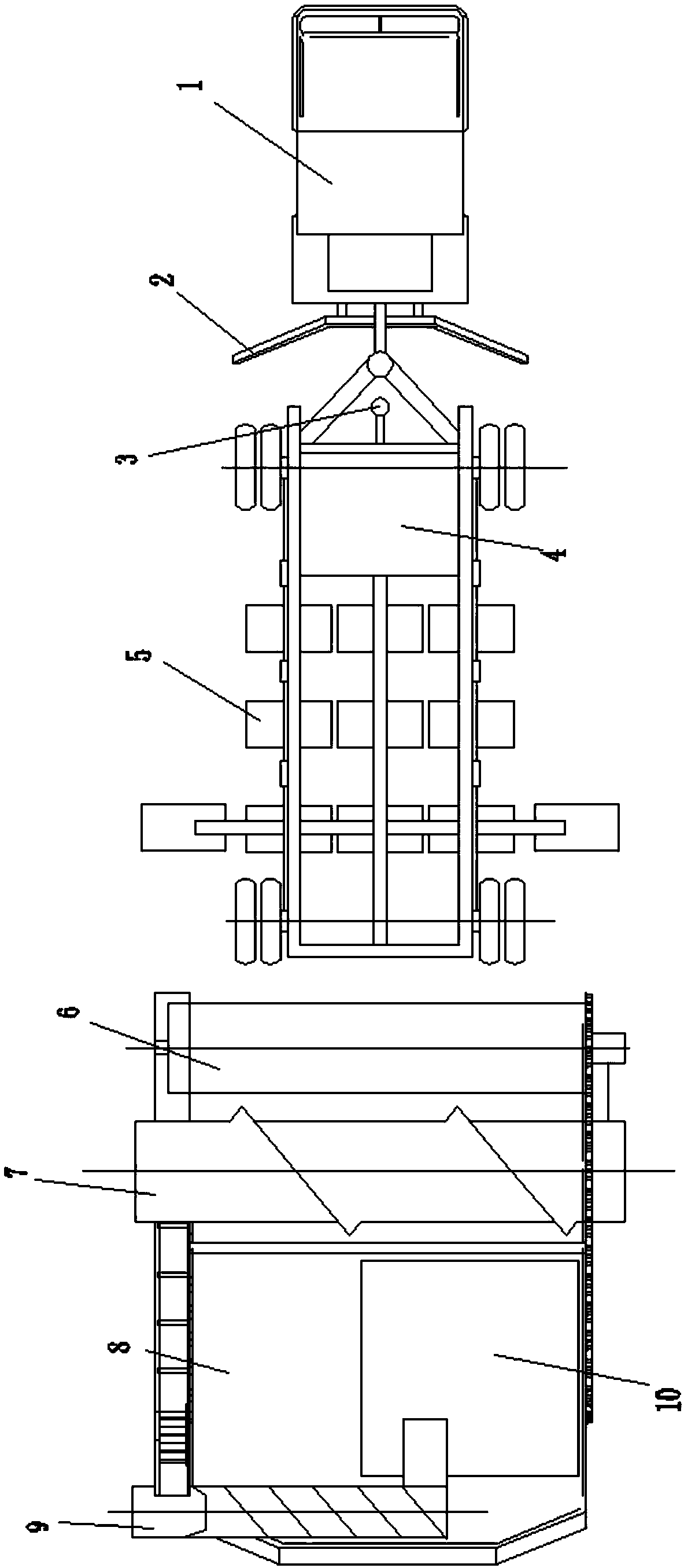

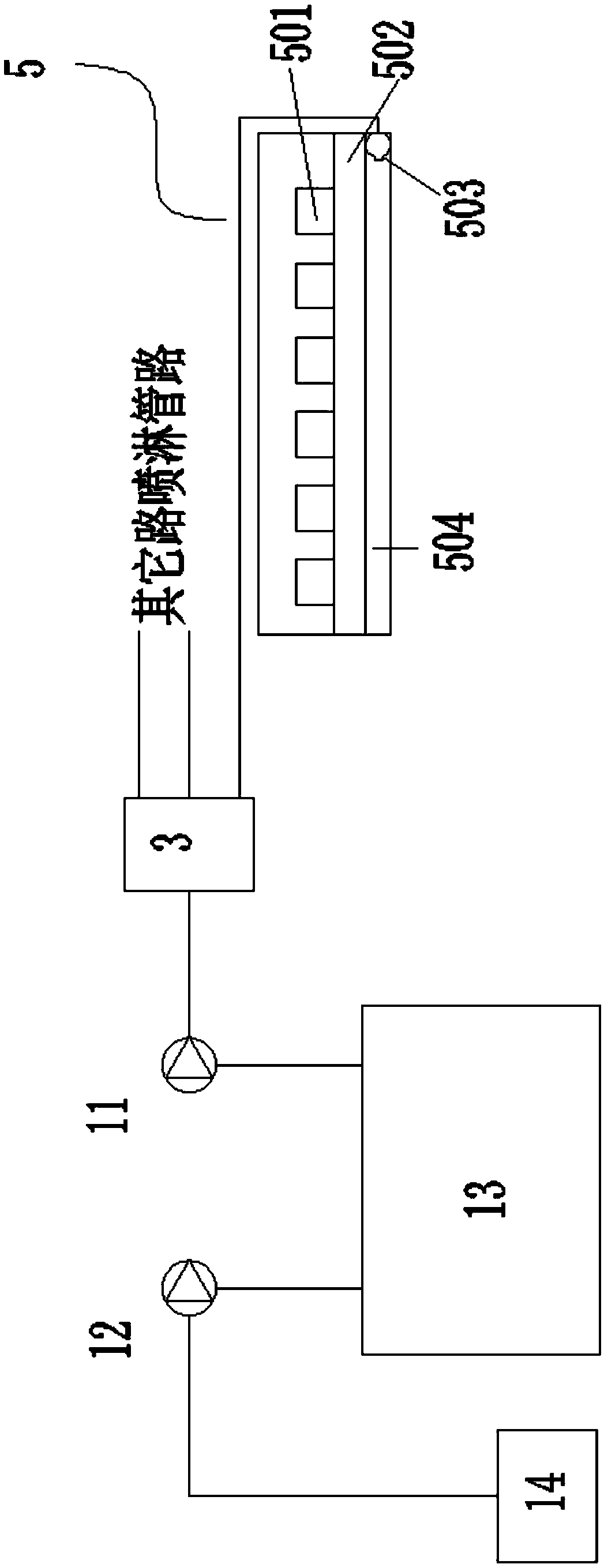

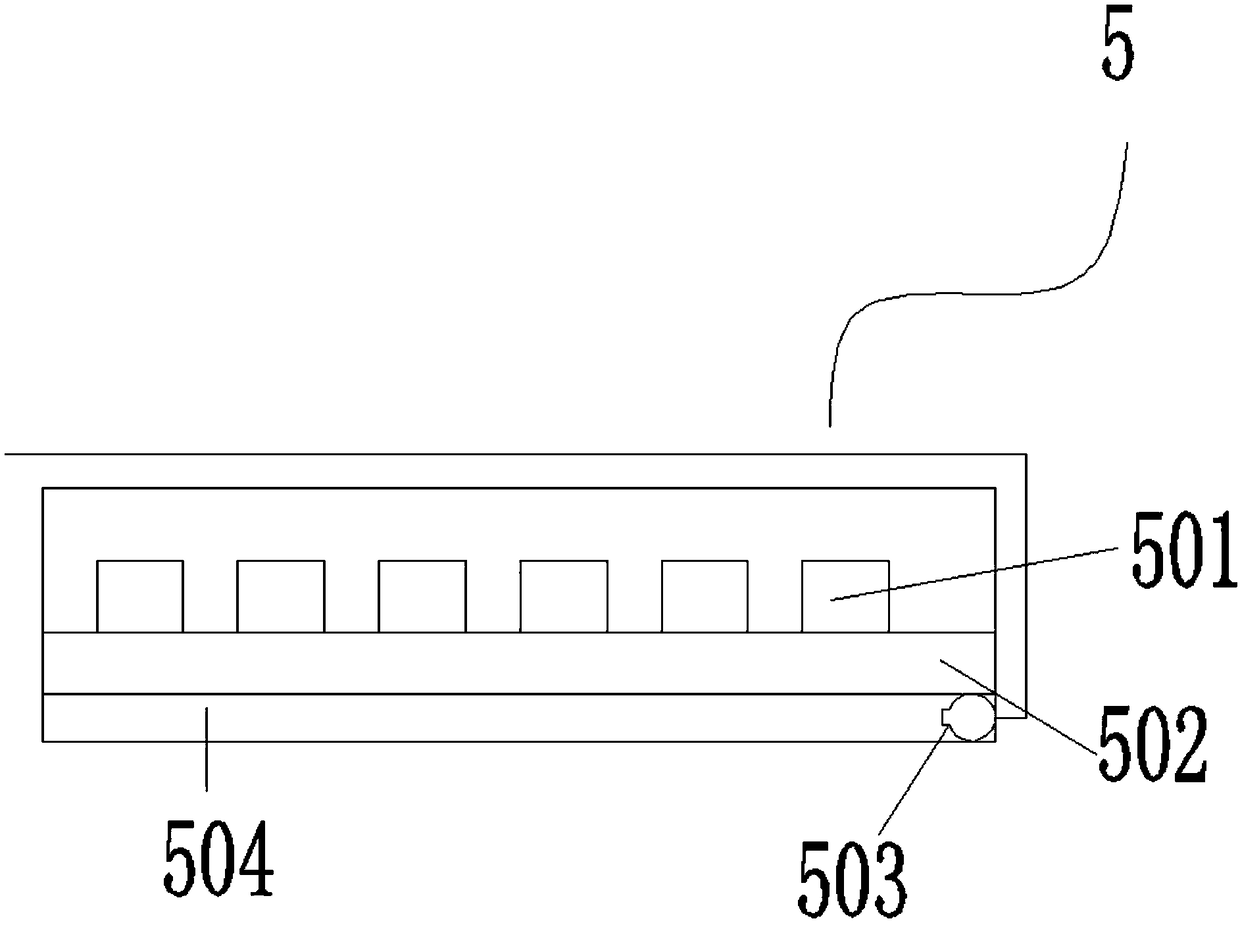

[0033] See Figure 1-3 , A mechanized harvesting equipment for shoal clams, which is characterized in that it comprises a tractor 1, a clam-extracting device, and a clam-harvesting device that are connected in sequence from front to back; the clam-extracting device includes machinery arranged in sequence from front to back. Vibration array 4, ultrasonic water circulation system; the ultrasonic water circulation system includes a water storage tank 13, a spray pump 11 connected in sequence, and also includes an ultrasonic generation array 5, the ultrasonic generation array 5 has an ultrasonic generation mechanism 501, an excitation Vibration plate 502, water spray pipe 503, said water spray pipe 502 is connected with spray pump 11, the spray direction of the nozzle on the side wall of water spray pipe 502 is forward, and the left and right sides and rear side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com