High energy pulsed spin plasma perforation method

A plasma and high-energy pulse technology, applied in the field of plasma perforation, can solve the problems of reducing oil and gas well production and production efficiency, decreasing rock permeability, and decreasing the connectivity between reservoir and wellbore, so as to improve production efficiency and total production. , the effect of improving connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

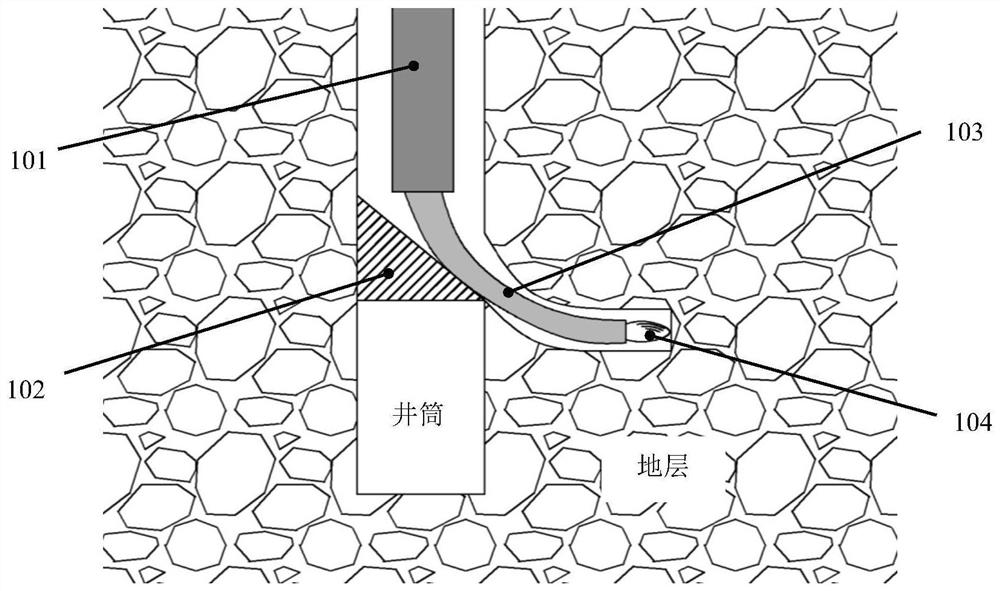

[0008] as Figure 1 As shown, after the completion of the drilling of the oil and gas well, the continuous tubing 101 will be the inclinator 102 and the high-energy pulse spin plasma drill bit 103 into the wellbore, after reaching a specific formation, the inclinator 102 generates an action under the action of the ground control signal, anchoring the casing; the high-energy pulse spin plasma drill bit 103 is biased to the side of the casing under the guiding action of the incliner 102; the ground control system sends out a control signal, and the high-energy pulse spin plasma drill bit 103 sprays out a high-energy pulse spin plasma 104 High-energy pulsed spin plasma melts the casing, annular cement and stratigraphic rock in turn, and continuously drills.

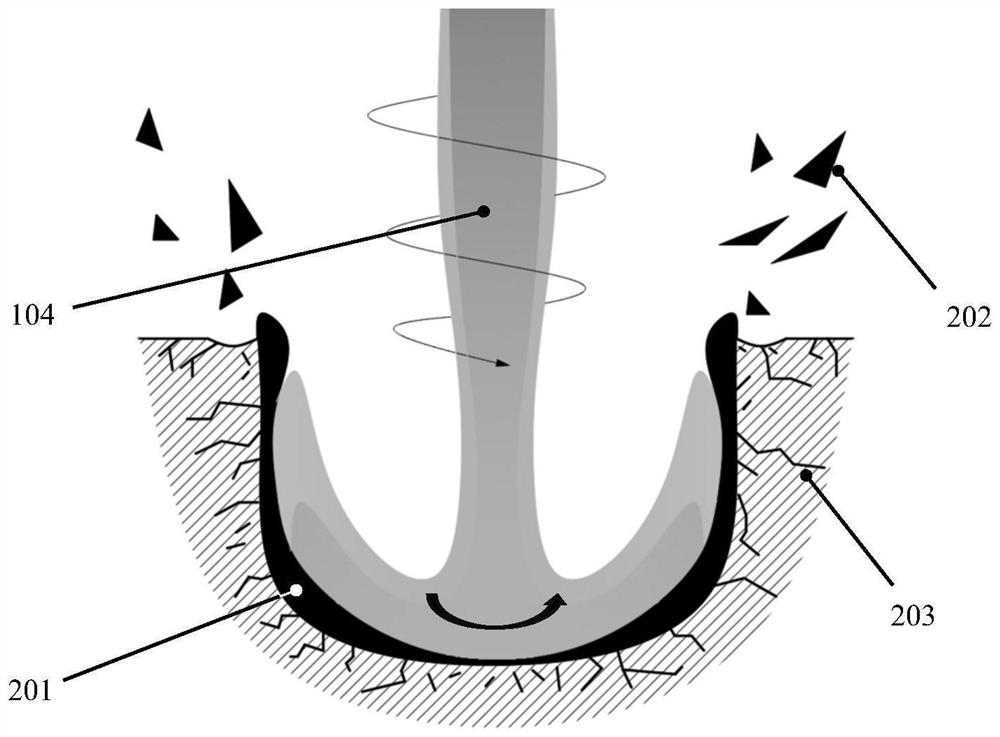

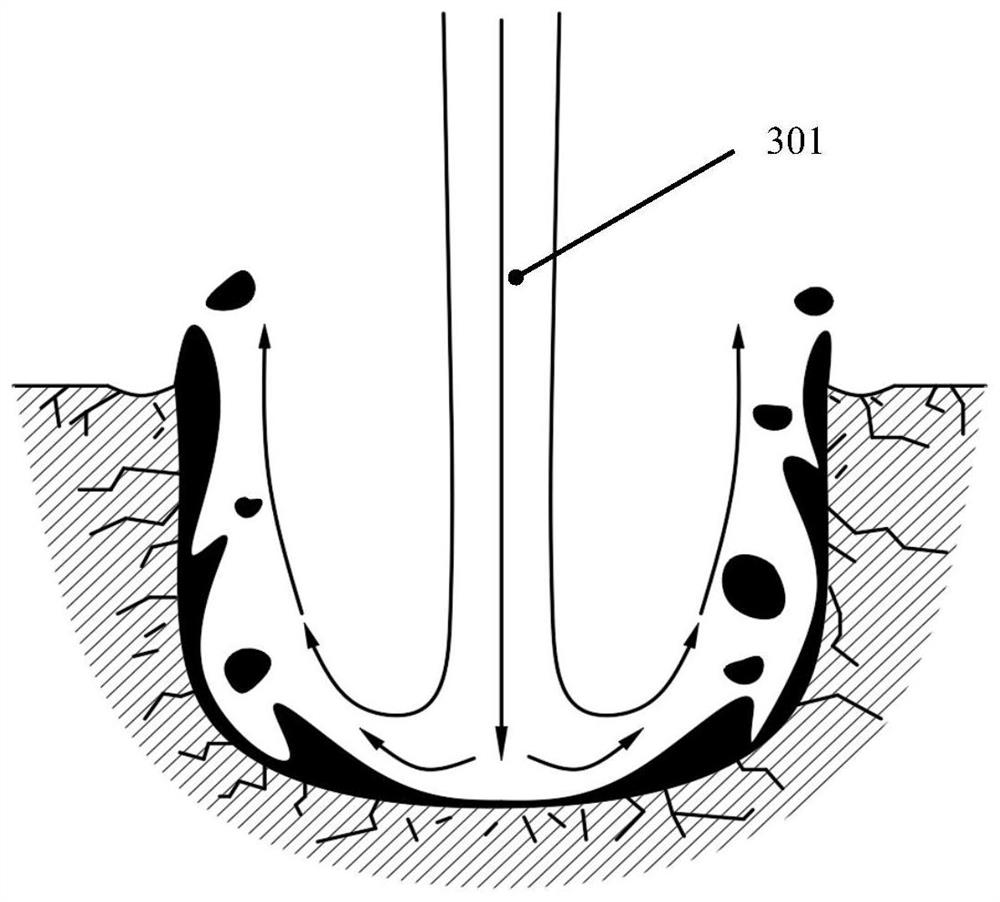

[0009] High-energy pulsed spin plasma 104 is ejected onto the rock surface as schematic Figure 2 As shown, the high-speed rotating high-energy pulse spin plasma 104 melts the rock, and a layer of molten magma is formed on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com