Manufacturing method of burner fire lid

A manufacturing method and burner technology, applied in the direction of combustion methods, burners, gas fuel burners, etc., can solve the problems of high environmental pollution, increased production costs, and useless fire caps, and achieve simple processing methods, low production costs, non-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

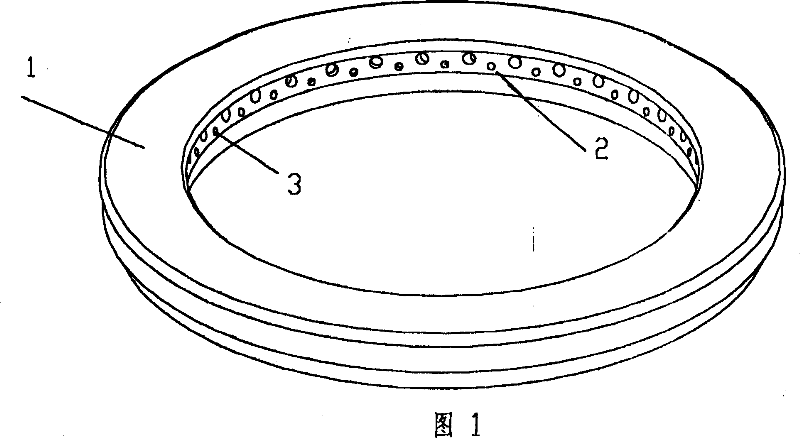

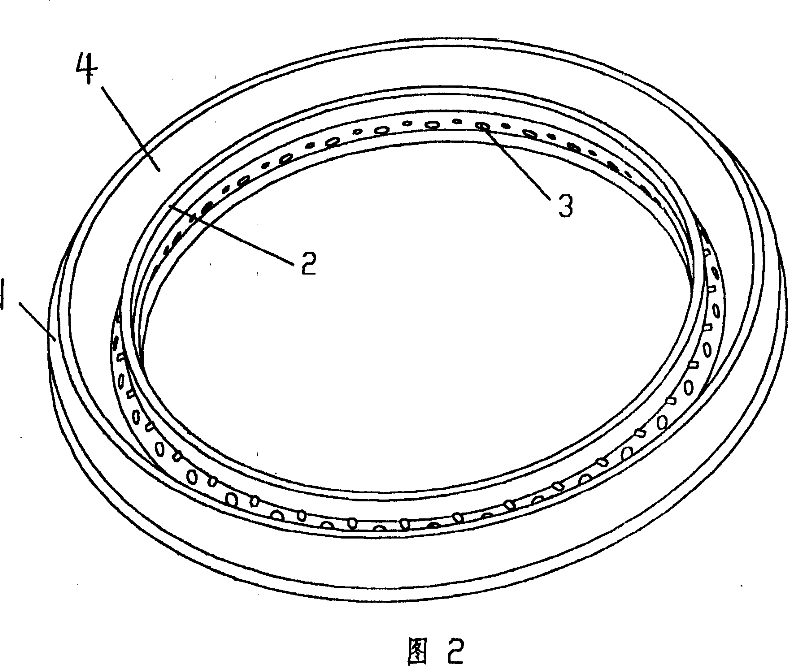

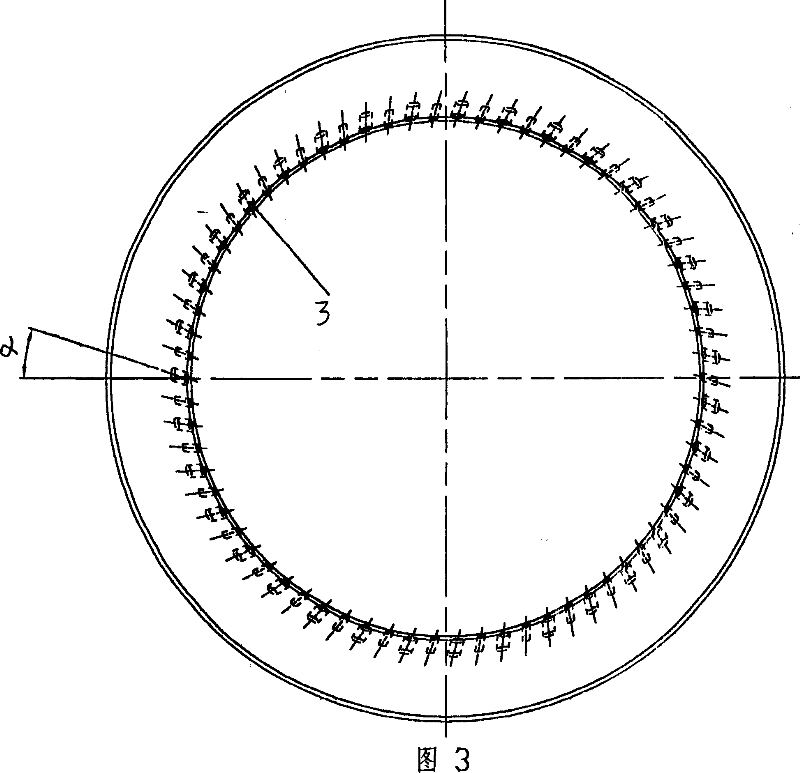

[0022] A kind of burner fire cover produced by the present invention, it comprises fire cover seat 1, is provided with gas channel 4 under fire cover seat 1, has on the fire hole circle 2 of described fire cover seat 1 inner side and this The fire hole 3 that gas channel 2 communicates, in order to make the gas combustion that comes out from fire hole 3 fully, reduce the pollution to environment, the direction of fire hole 3 and the radial direction of this fire hole ring 2 are set to certain angle α ( As shown in Figure 3), make the fire hole 3 inclined from bottom to top and also form a certain angle β (as shown in Figure 4) with the plane direction simultaneously. In this way, the firepower after the combustion of the gas can be concentrated and just aligned with the cooking utensils on the burning range, and the combustion utilization rate of the gas can be improved. Usually, the angle α formed between the fire hole 3 and the radial direction of the fire hole ring 2 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com