Special frying machine for quick-frozen semi-finished products of deep-fried twisted dough sticks

A special oil and frying machine technology, which is applied in the direction of oil/fat baking, etc., can solve the problems of small size, small expansion of fried dough sticks, uneven color of finished fried dough sticks, etc., and achieve the effect of simple equipment structure, small size and excellent taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

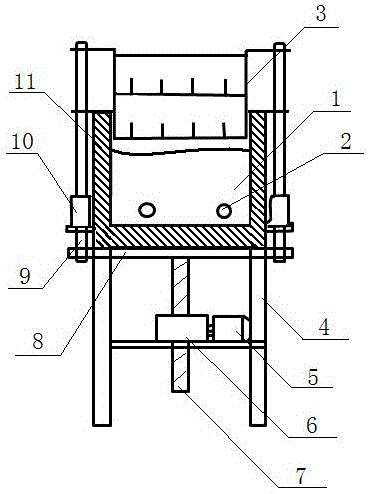

[0020] A deep-frying machine for quick-frozen deep-fried dough stick embryos, comprising a frying box 1 containing a heating assembly 2, at least one layer of frying baskets 3 having several intervals are arranged in the frying box 1, and the frying baskets 3 are driven by a driving mechanism. Compared with the up-and-down movement of the oil surface in the fryer 1, the quick-frozen fried dough stick embryos placed in the fryer basket 3 follow the law of the up-and-down movement of the fryer basket, move to the bottom of the oil surface for frying, and then move to the oil surface to release steam To expand, repeat until frying is complete.

[0021] The quick-frozen deep-fried dough stick embryos are obtained by making deep-fried dough stick embryos that are indented, and then quickly sent to a quick-freezing tunnel for quick freezing after being pulled.

Embodiment 2

[0023] Such as figure 1 The special deep-frying machine for quick-frozen deep-fried dough sticks is shown as a realization structure of Embodiment 1. A bracket 4 is set at the bottom of the frying box 1, and a driving mechanism is set on the bracket.

[0024] The driving mechanism is composed of a driving motor 5, a speed reducer 6, a transmission screw 7, a transmission plate 8, a transmission rod 9 and a linear bearing 10, wherein the driving motor 5 is connected to the speed reducer 6, the speed reducer 6 is connected to the transmission screw 7, and the transmission One end of the screw mandrel 7 is installed in the central position of the drive plate 8, and two drive rods 9 are arranged at the two ends of the drive plate 8, and the drive rod 9 passes through the linear bearing 10 to connect the frying basket 3.

Embodiment 3

[0026] As a further optimized structure of Example 2, the frying basket 3 is provided with two layers, and each layer contains a space for placing 5-10 quick-frozen fried dough stick embryos.

[0027] An insulating layer 11 is arranged in the casing wall of the frying casing 1, and a heating assembly 2 is arranged in the casing.

[0028] A temperature sensor is also arranged in the casing of the fryer 1, and a control mechanism is also arranged on the support 4. The control mechanism connects the temperature sensor and the heating pipe, receives the temperature of the temperature sensor and controls the heating pipe to work.

[0029] The control mechanism is connected to the drive motor to control the speed or time of the drive mechanism moving up and down.

[0030] For the above-mentioned embodiment, as the driving mechanism in embodiment 2, we can also use a cam mechanism to realize it, and of course it can also be other structures, the purpose of which is to make the frying...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap