Adjustable oven special for automobile lamp

An automotive lamp, adjustable technology, applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., can solve the poor curing effect of the lamp body and lamp housing, and the inability to bond the lamp body and lamp housing , Unreliable bonding and other problems, to achieve the effect of improving the bonding curing effect, shortening the curing time, and improving the curing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

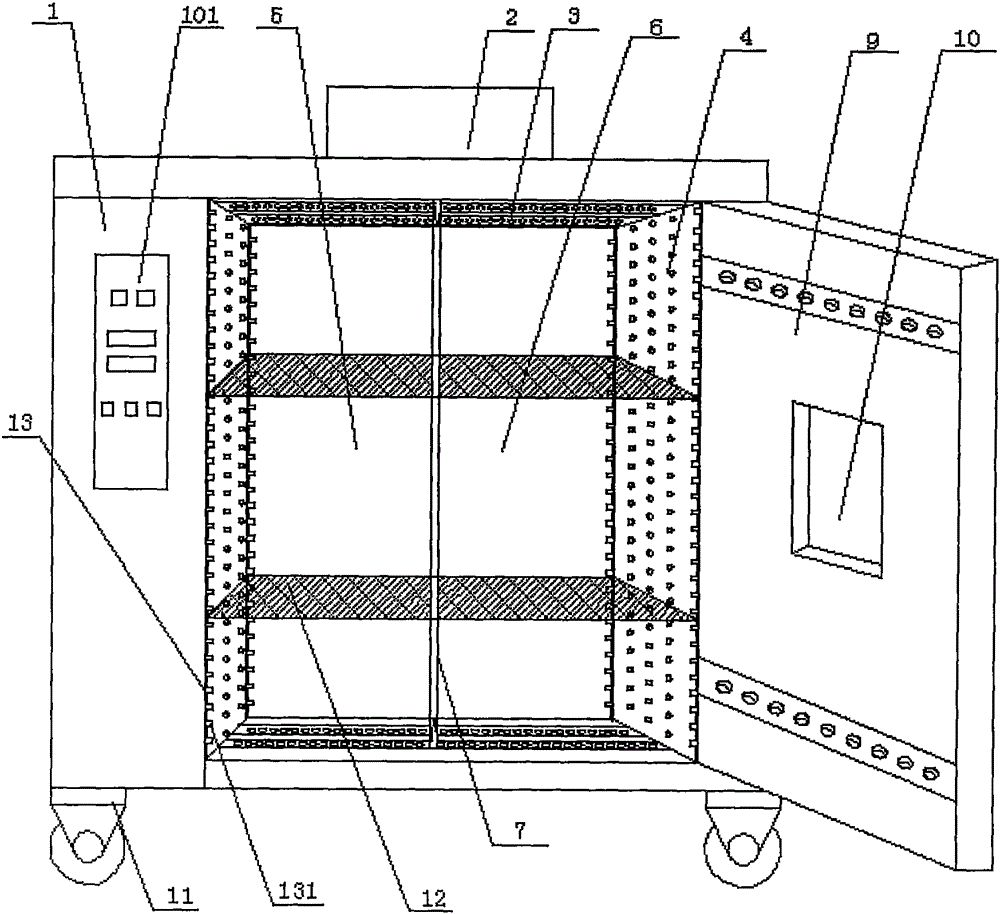

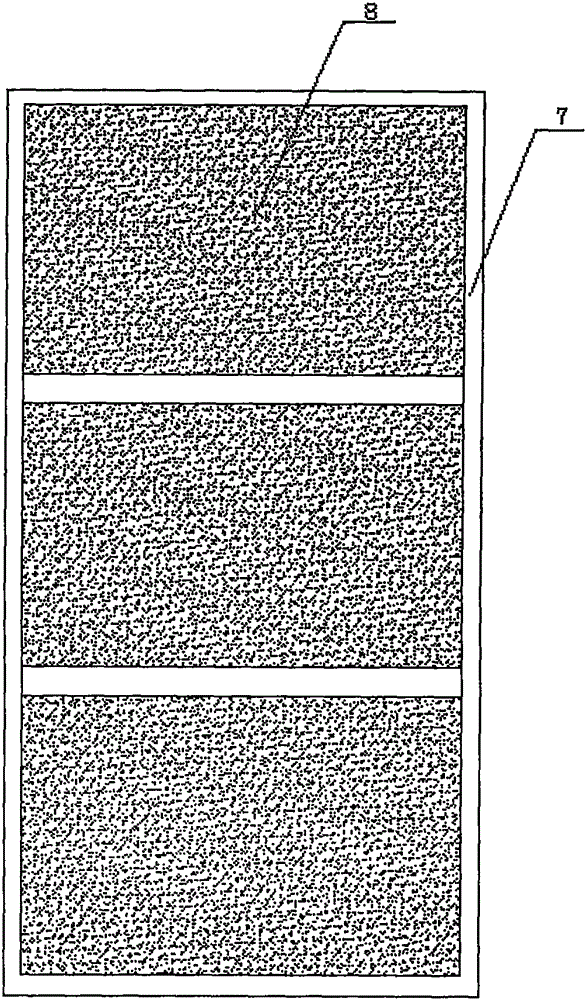

[0019] Refer to attached Figure 1-2 The shown special oven for adjustable car lights includes an oven body 1 and a door 9 that is movably connected with the oven body 1. A ring of sealing gaskets is also arranged on the door 9, and the sealing gaskets can play Good sealing and heat preservation effect, to prevent heat loss, the door 9 is also provided with an observation window 10, the observation window 10 is arranged in the middle of the door 9, and its area accounts for 1 / 4 of the area of the door 9, the said The four corners of the bottom of the oven body 1 are equipped with universal wheels 11, and the universal wheels 11 are fixed on the bottom four corners of the oven body 1, and the position of the oven b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com