Instrument lathe electromechanical integrated spindle box and auxiliary structure

A technology of instrument lathe and spindle box, applied in the field of mechatronics structure of instrument lathe spindle box, can solve the problems of high rod noise and energy consumption, large mechanical vibration, small axial installation space, etc. The effect of increasing the number and improving the space utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the specific implementation manner of accompanying drawing:

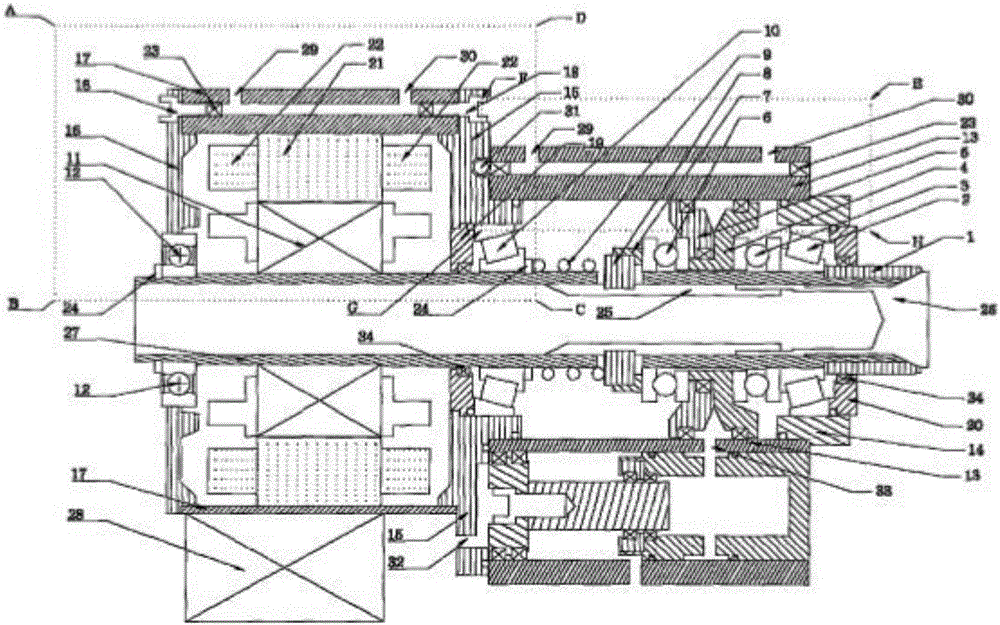

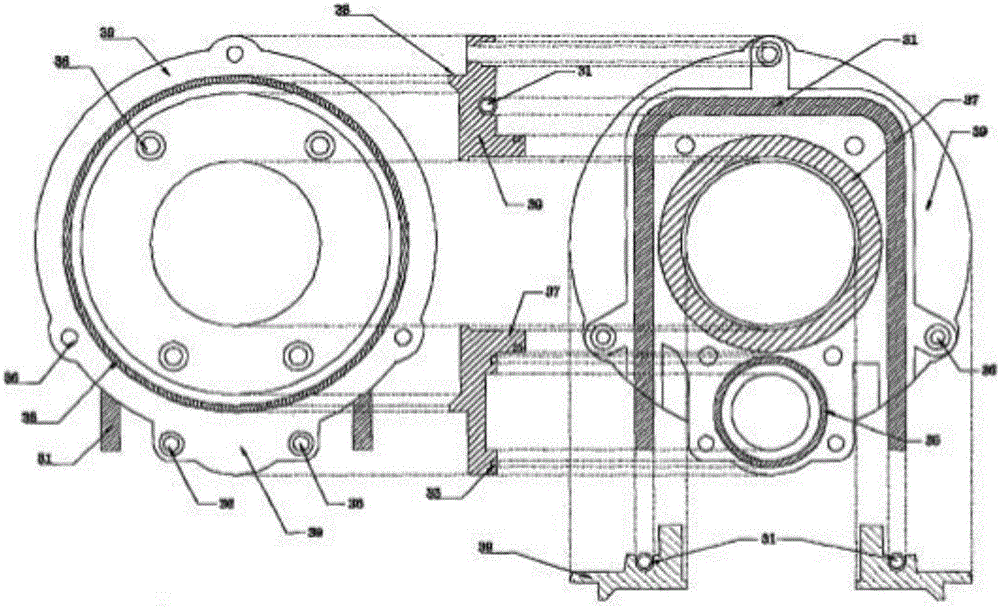

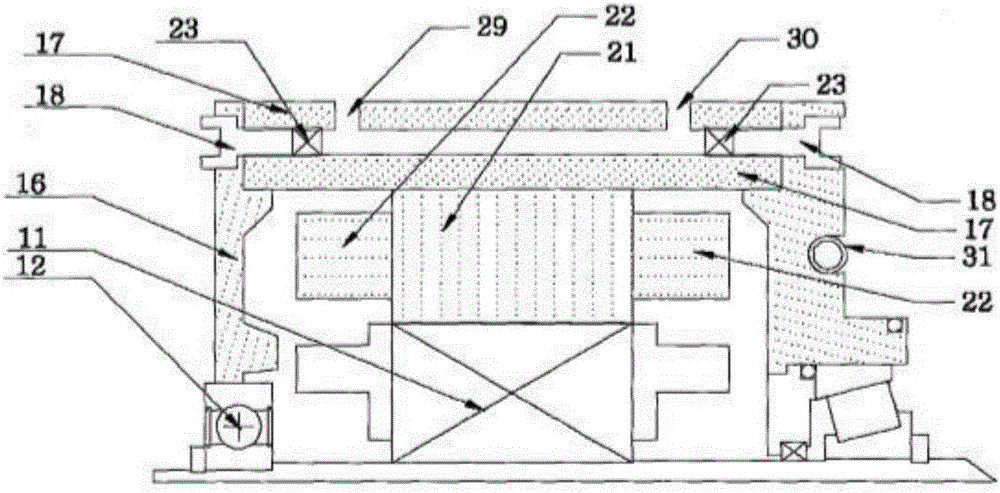

[0031] figure 1Shown is the half-section diagram of the overall embodiment of the present invention, as shown in the figure: the clamping mechanism of the instrument lathe is built in the main cylinder of the main shaft box (13); the motor rotor (11) is installed in the hollow main shaft (27); the motor stator (21) Installed on the motor casing (17); the motor casing (17) is coaxially fixed to the main cylinder of the main shaft box (13) through the flange (15); the front end of the main shaft box (13) is provided with a front cover (14) and a seal Cover; the rear end of the motor casing (17) is provided with a rear end cover (16); the front end cover (14) is installed with a front support bearing (2); the flange (15) is installed with a rear support bearing (10); the rear end cover (16) Auxiliary bearings (12) are installed; wear-resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com