Tread pattern for truck mine tyre

A technology for tire treads and trucks, used in tire treads/tread patterns, heavy tires, heavy vehicles, etc. The effect of premature aging, enhanced service life, and enhanced rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

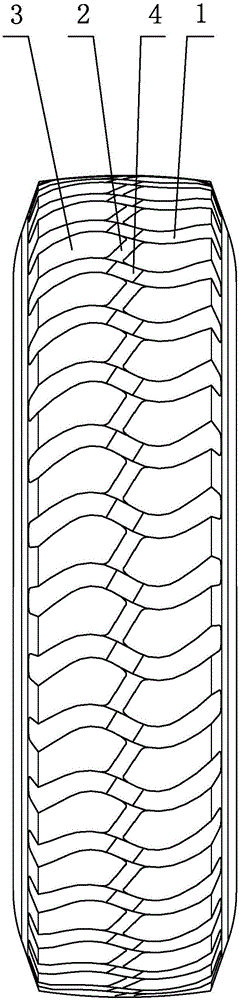

[0017] The tread pattern of the truck mining tire of the present invention includes transverse wave-shaped main pattern grooves 1, and the transverse wave-shaped main pattern grooves 1 are evenly distributed on the tread and divide the tread into circumferentially evenly distributed transverse waves. shaped large pattern block, the width of the transverse wavy large pattern block is twice the width of the transverse wavy main pattern groove 1, such as figure 1 shown.

[0018] The composition of the transverse wavy main groove 1 includes left crest grooves (convex) and right trough grooves (concave) on both sides of the tread centerline, and right trough grooves adjacent to the transverse wavy main groove 1 The groove and the left crest groove are connected by oblique auxiliary grooves 2, the oblique direction of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com