Pressure sensor

A pressure sensor and sensor component technology, applied in the direction of measuring fluid pressure, instruments, measuring fluid pressure through electromagnetic components, etc., can solve problems such as error signal analysis, signal transmission distortion, and changing the leakage current of pressure sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

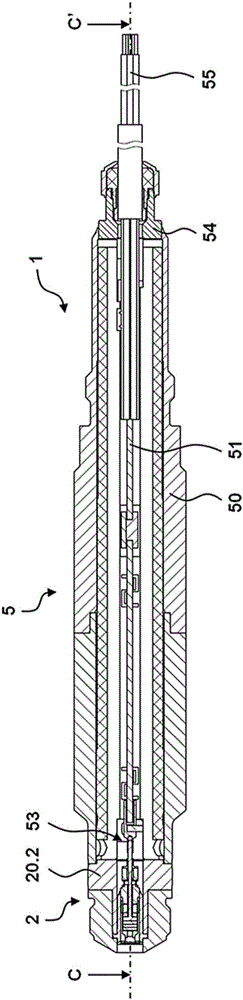

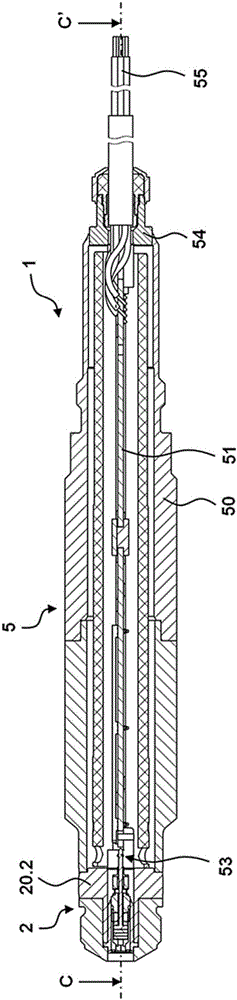

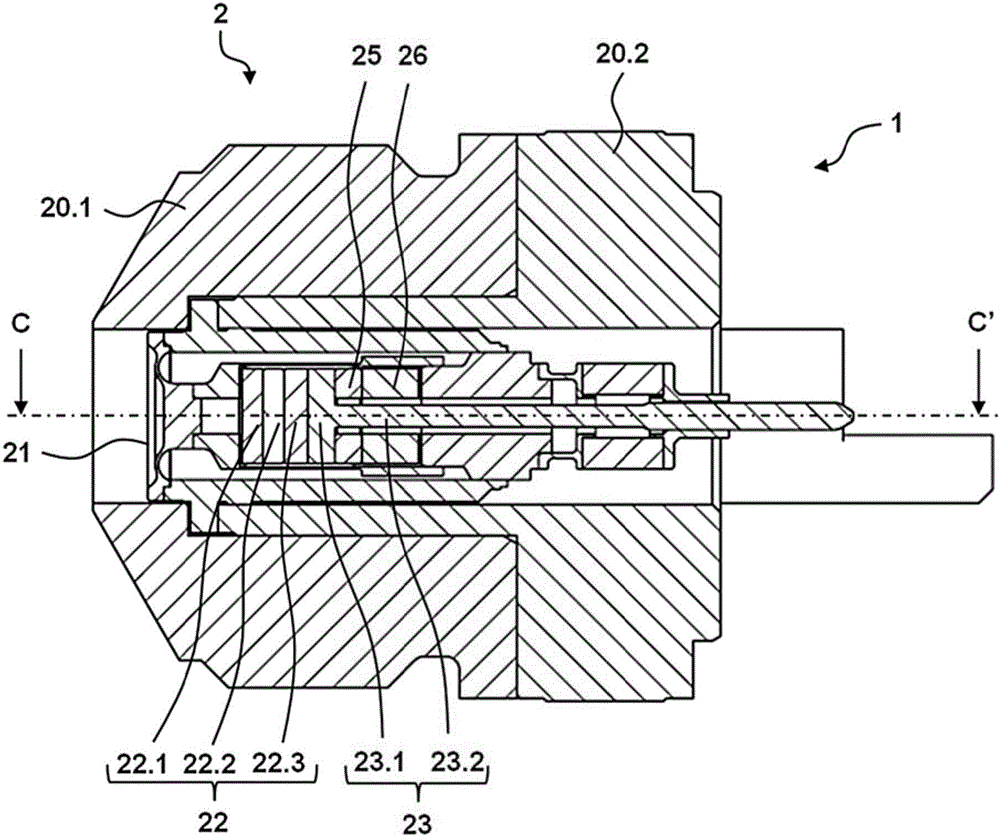

[0063] figure 1 with figure 2 Sections of two embodiments of the piezoelectric sensor 1 according to the invention are shown. These sections are shown along the longitudinal axis CC' of the piezo pressure sensor 1 after it has been inserted and assembled. The longitudinal axis CC', the vertical axis AA' and the horizontal axis BB' are perpendicular to each other. The direction along the longitudinal axis CC' is also referred to as the longitudinal direction, and the direction perpendicular to this longitudinal direction is also referred to as the radial direction. The vertical axis AA' and the horizontal axis BB' develop into a radial plane AB. The radial direction lies in this radial plane AB. The piezoelectric pressure sensor 1 and its components are substantially circular in cross-section with respect to the longitudinal axis CC'. The adjective "substantially" includes ±10% circular shape variations. However, within the understanding of the present invention, the pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com