Long-lifetime LED drive circuit

A driving circuit and long-life technology, which is applied to the layout of electric lamp circuits, electric light sources, lighting devices, etc., can solve the problems of short service life, fragility, and low luminous efficiency, and achieve long service life, suppression of instantaneous high voltage, and high application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

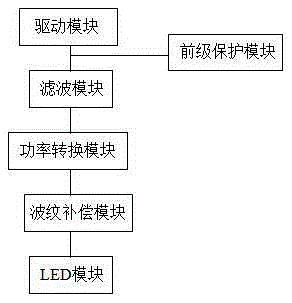

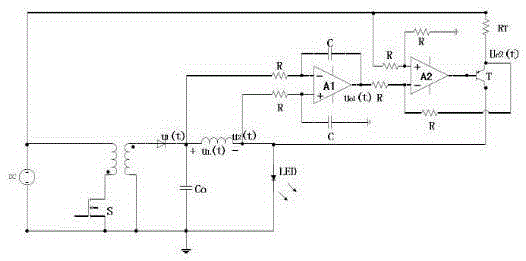

[0015] An LED long-life drive circuit, the drive circuit includes a drive module, a pre-stage protection module, a filter module, a power conversion module and an LED module, the drive module provides constant current and voltage, the pre-stage protection module and filter The module is connected to the drive module. The pre-stage protection module measures and evaluates the parameters to prevent the peak voltage or current from causing damage to the subsequent modules. The filter module is connected to the pre-stage protection module. The filter module can filter out the electromagnetic pair circuit The power conversion module is connected with the filter module and the LED module. The power conversion module can filter out the peak voltage, convert the input power into the design power, and then convert the high-frequency pulse signal into a stable DC power and send it to the LED module. .

[0016] The pre-stage protection module includes a fuse, a surge current suppression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com