Structure of end part of weather strip and the forming method thereof

A technology of end structure and sealing strip, which is applied in the direction of sealing device, engine sealing, wing fan operating mechanism, etc., can solve the problem of sealing strip not being installed in a stable state, and achieve the effect of strong fitting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Next, the end structure of the weather strip according to the embodiment of the present invention will be described with reference to the drawings.

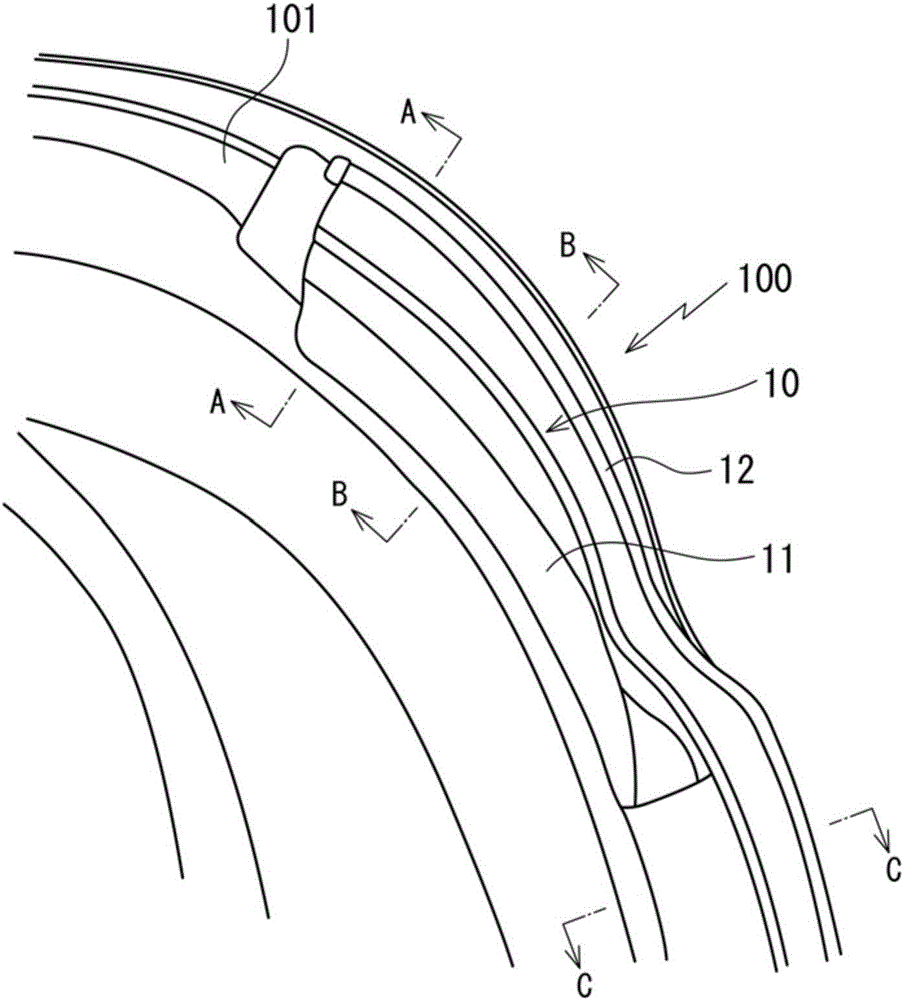

[0066] The end structure of the sealing strip of the embodiment of the present invention, such as figure 1 , Figure 9 , Figure 10 As shown, the slide door 100 that moves forward and backward along the body of a station wagon, a van, or a sedan is attached to a section L where the flange 101 cannot be set.

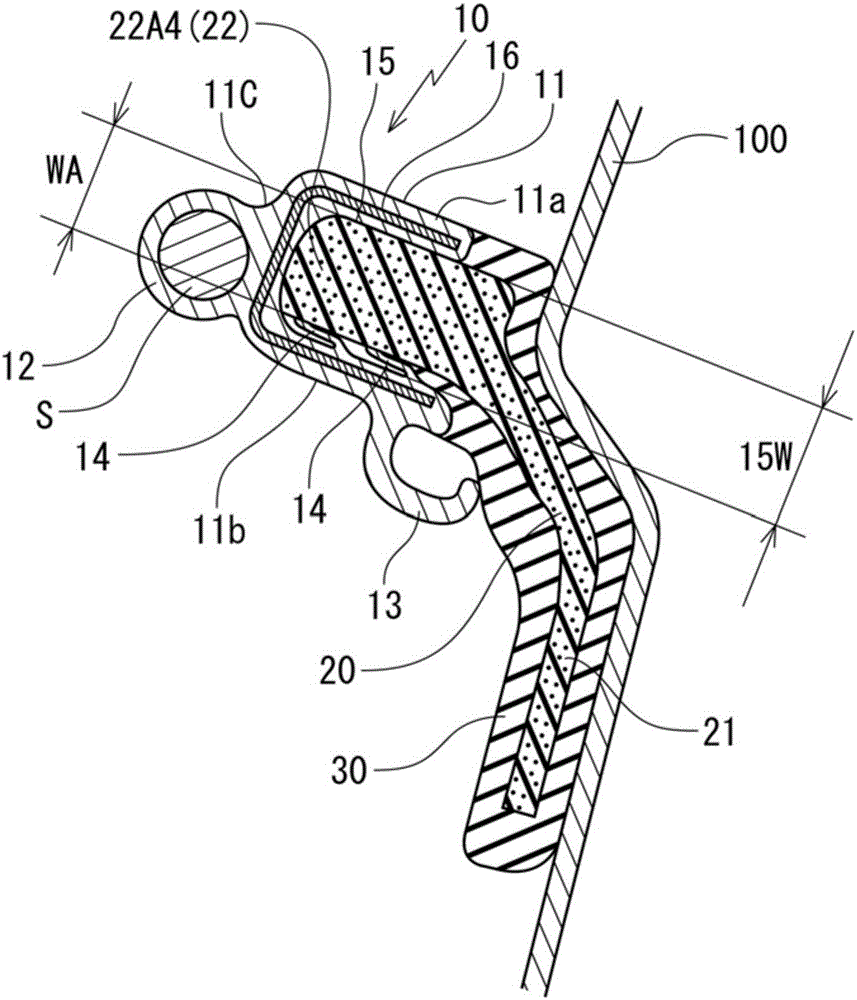

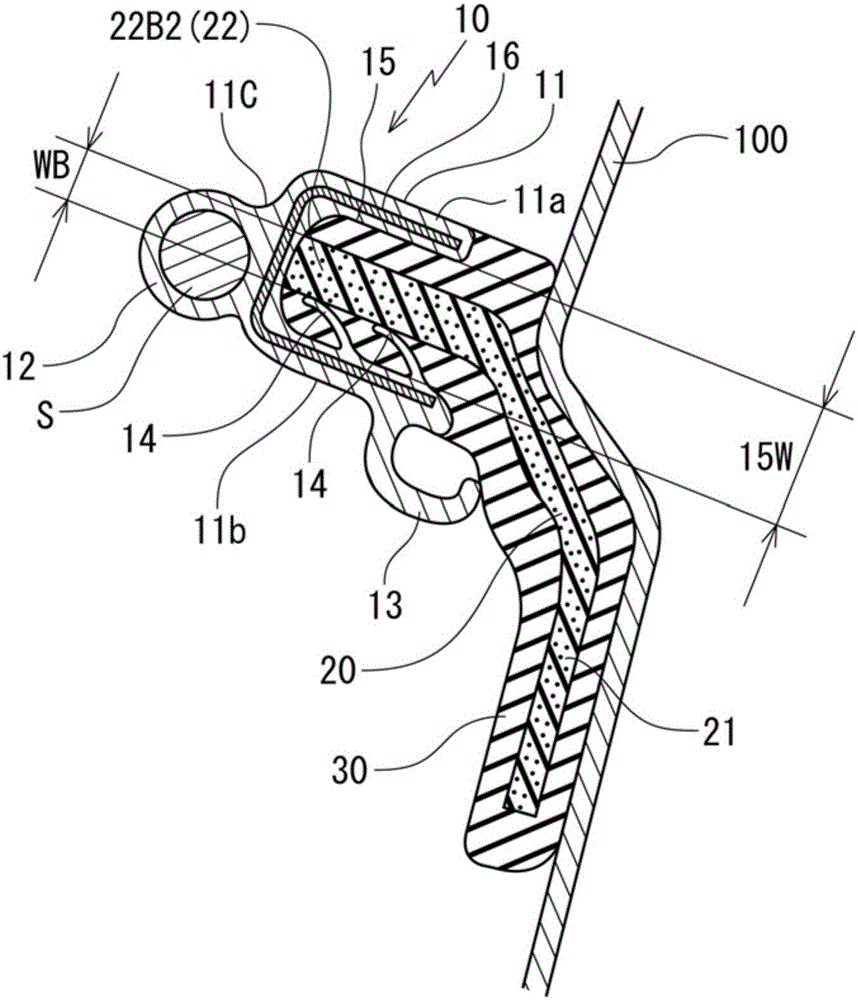

[0067] like Figure 2 to Figure 4 As shown, the weather strip 10 is formed by integrally forming a hollow portion 12 on an installation base 11 having a substantially U-shaped cross section, and an insert 20 is embedded therein. In addition, the hollow portion 12 is a hollow portion extending in the up-down direction for later inserting a sensor (pressure-sensitive sensor) S for when the sliding door 100 is sandwiched between the door opening. When a foreign object such as a part of the human body (finger or hand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com