Material frame buffering cushioning device

A buffer device and material rack technology, applied in the field of material racks, can solve problems such as too late to operate, fast delivery of parts, and affect work efficiency, so as to achieve high work efficiency, low cost, and avoid over-fast delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

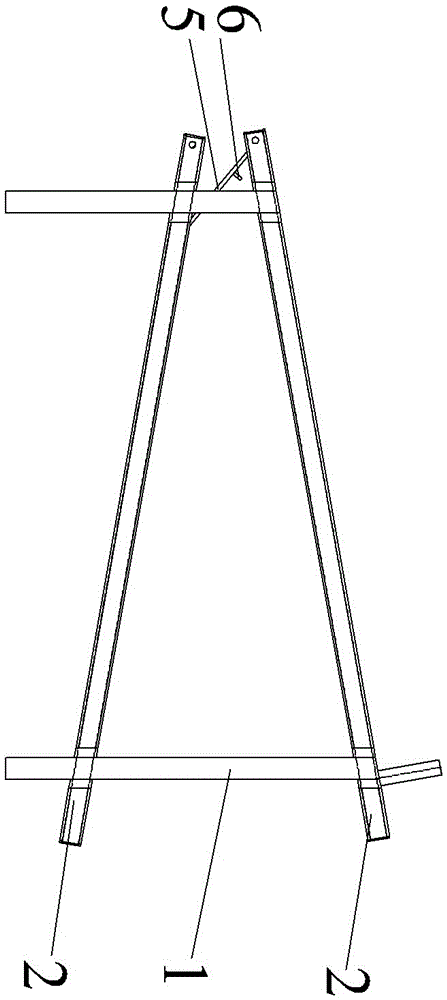

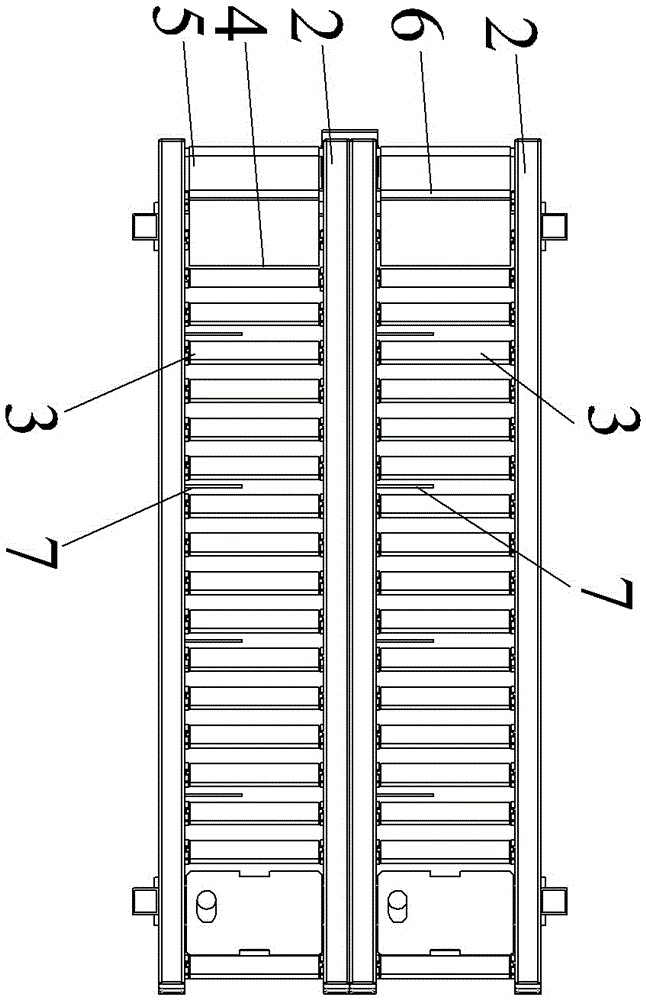

[0011] like figure 1 , figure 2 As shown, the present invention comprises frame 1, and frame 1 is provided with two layers of conveying frame 2, and conveying frame 2 is inclined arrangement, and the inclination angle of conveying frame 2 is 36 °, is convenient to automatic slide of workpiece; Frame 2 also can be provided with a plurality of side-by-side conveyings according to the situation, and is preferably 2, thereby improves work efficiency; Every layer of conveying frame 2 is all provided with conveying roller 3, after workpiece is placed on conveying frame 2, by conveying roller 3 automatically Conveying slides down, and the end-to-end connection between the conveying racks 2 is provided with a gap 4 at the tail end of the upper conveying rack 2. The bottom of one end is connected to one end of the elastic element (not shown in the figure), and the other end of the elastic element is fixed on the conveyor frame 2 corresponding to the lower layer, and a stopper 6 is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com