Waste heat recovery device of environment-friendly mechanical spraying equipment

A technology of waste heat recovery equipment and mechanical equipment, which is applied in the direction of spraying devices, spray paint booths, etc., can solve the problem of the decline of the heat conduction effect of the heat recovery plate, and achieve the effect of preventing the heat from being too late to dissipate heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

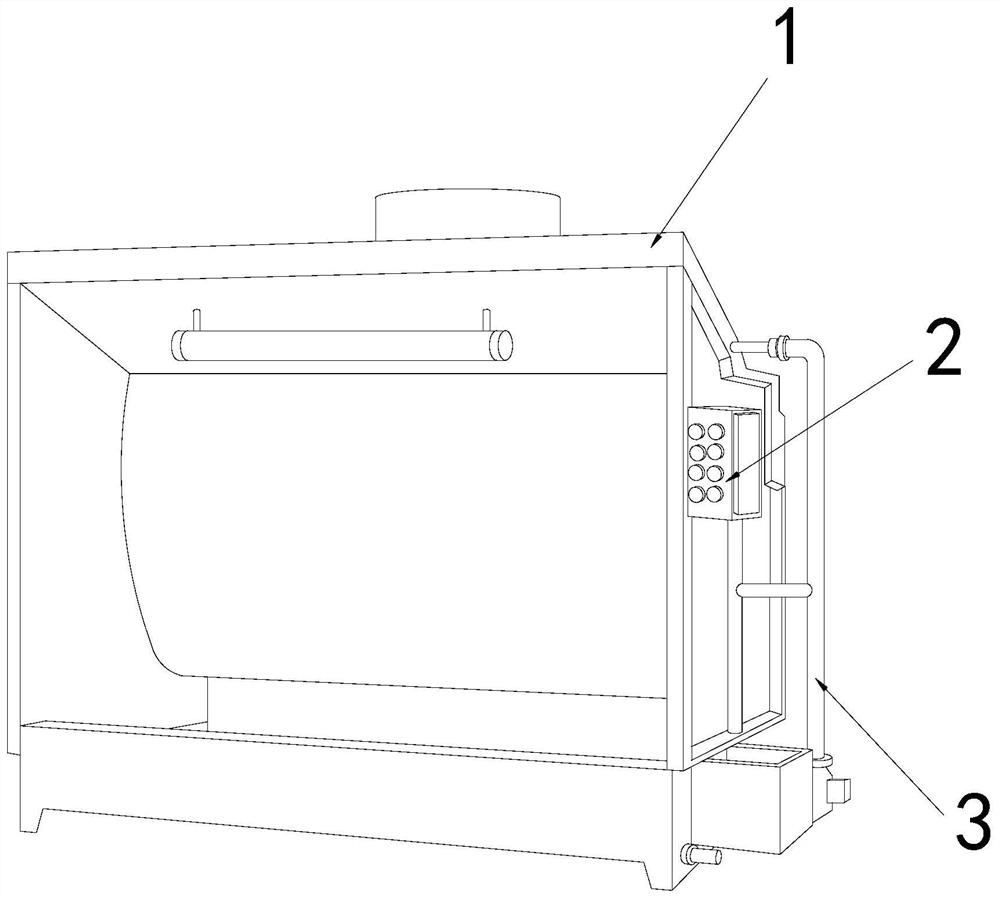

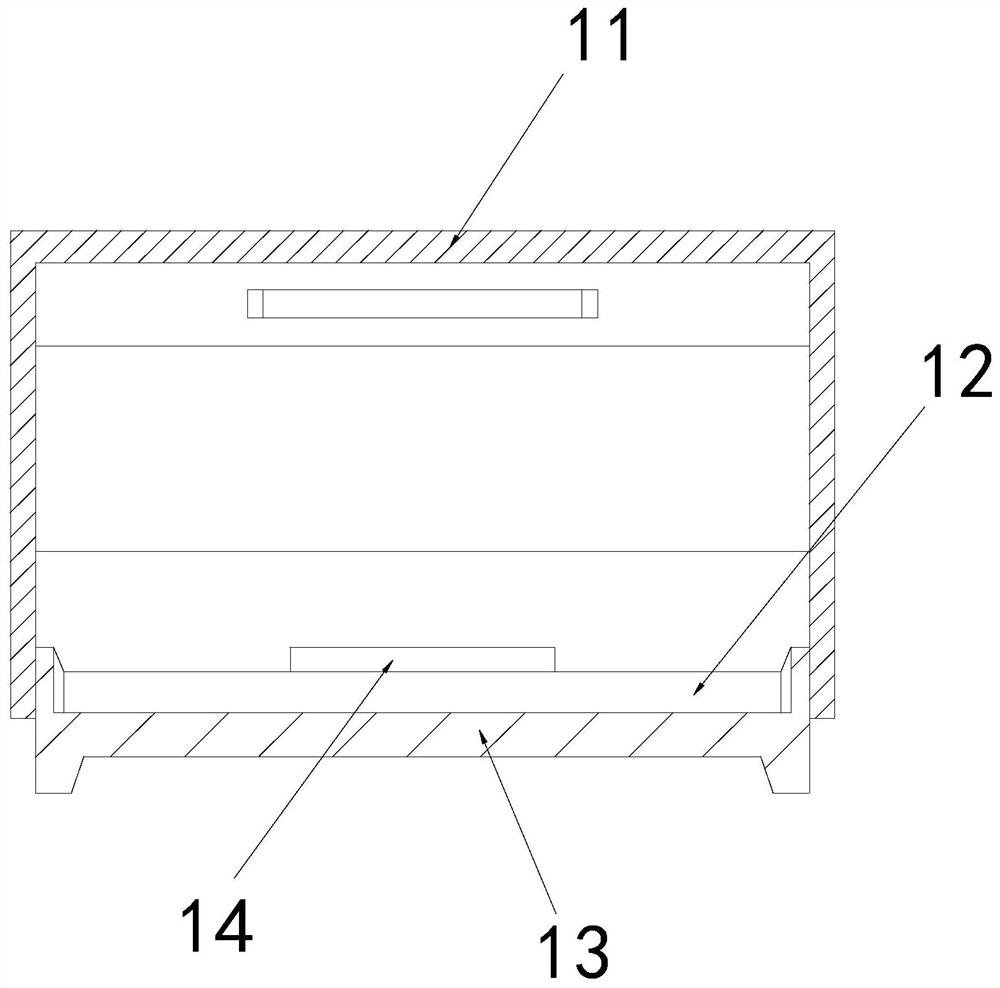

[0027] The invention provides a waste heat recovery equipment for coating environmental protection mechanical equipment. Its structure includes a body 1, a control electric box 2, and a material guide pipe 3. The control electric box 2 is embedded and connected to the right side of the body 1. The body 1 and the material guide pipe 3 are an integrated structure; the body 1 includes a frame body 11, a heat recovery plate 12, a bottom frame 13, and an operating table 14, and the heat recovery plate 12 is embedded in the inner position of the bottom frame 13 , the bottom frame 13 and the frame body 11 are of an integrated structure, and the console 14 is installed on the upper surface of the bottom frame 13 .

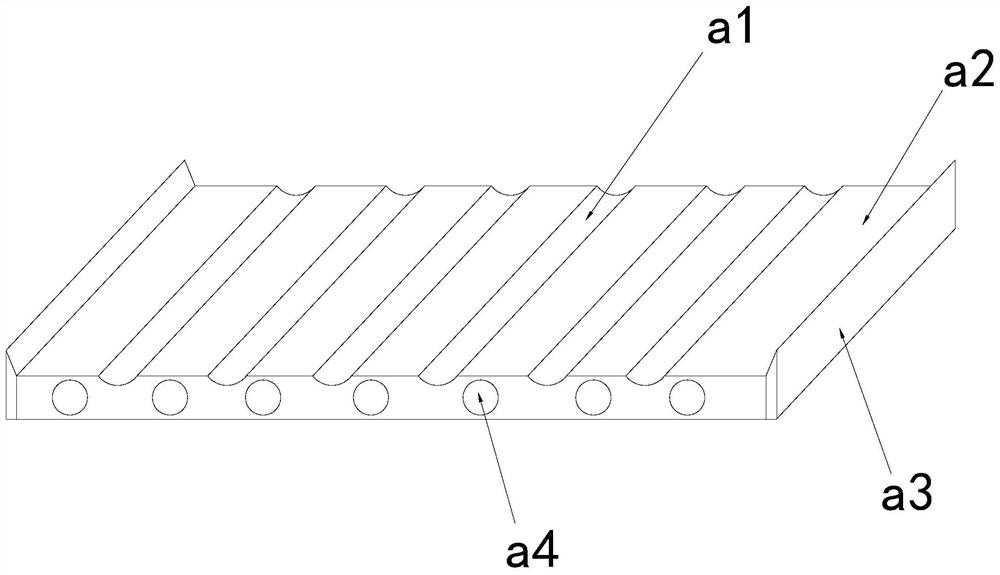

[0028] Wherein, the heat recovery plate 12 includes a collecting groove a1, a plate body a2, an connecting plate a3, and a cooling chamber a4, the collecting groove a1 and the plate body a2 are an integrated structu...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035]Wherein, the heat dissipation cavity a4 includes an introduction strip c1, an outer ring c2, a middle solid block c3, and a heat dissipation tooth c4, the introduction strip c1 is embedded in the inner position of the outer ring c2, and the middle solid block c3 is fixed on the outer ring c2 In the middle position, the heat dissipation teeth c4 and the lead-in bar c1 are an integrated structure, and the lead-in bar c1 is made of copper metal with strong thermal conductivity, and the heat of the object can be introduced into the interior of the outer ring c2 through the lead-in bar c1.

[0036] Wherein, the middle solid block c3 includes a linkage plate c31, a coupling block c32, a resilient piece c33, and a fixed block c34. The linkage plate c31 is embedded and fixed on the outer surface of the coupling block c32. Hinge connection, the rebound piece c33 is installed between the fixed block c34 and the linkage pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com